Product Advantage

1. Enhanced Accuracy: With precise measurement and control systems, the machine ensures accurate fills every time, minimizing product giveaway and maximizing cost-effectiveness.

2. Improved Product Quality: The automatic filling machine minimizes the risk of human errors and contamination, preserving the integrity and consistency of the filled products.

3. Increased Efficiency: By automating the filling process, the machine operates at high speeds, significantly boosting production rates and overall efficiency.

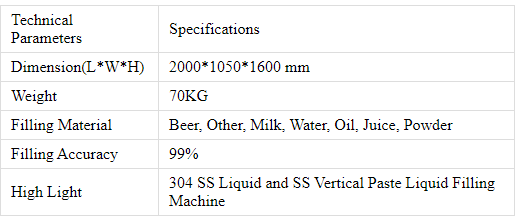

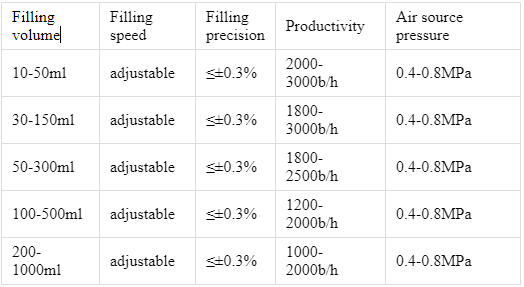

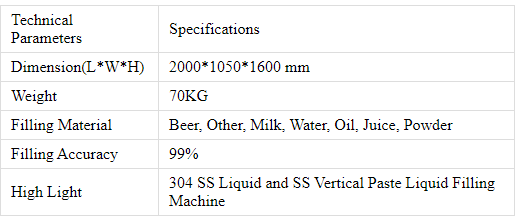

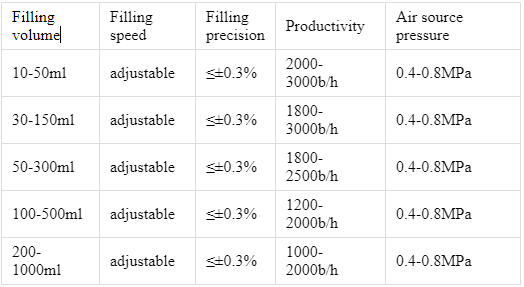

Technical Parameters:

Specification:

Product Uses:

This high-speed machine maximizes productivity and efficiency while maintaining exceptional product quality. Ideal for industries such as food and beverage, pharmaceuticals, and cosmetics, the automatic filling machine is an indispensable asset for businesses seeking enhanced production processes.

Product Operate Guide:

1. Pre-Production Checks: Before starting the filling process, ensure that all components, such as hoses, nozzles, and valves, are securely connected and in good condition. Verify that the machine is clean and free from any residual product.

2. Priming and Purging: Prime the filling machine by running a few cycles with the product to ensure proper flow and remove any air bubbles. Purge the machine of any remaining product from previous runs to prevent cross-contamination.

3. Operator Safety: Train operators on the safe use of the filling machine, including wearing appropriate personal protective equipment (PPE) such as gloves and safety goggles. Emphasize proper handling of chemicals or hot liquids, if applicable.

4. Production Monitoring: Regularly monitor the filling process to ensure consistent performance. Check for any anomalies, such as leaks, overfills, or underfills, and take corrective actions immediately to maintain product quality and prevent waste.

5. Cleaning and Maintenance: Follow a regular cleaning and maintenance schedule to keep the filling machine in optimal condition. Clean components thoroughly after each production run and perform routine maintenance tasks, such as lubrication and replacement of worn parts, as recommended by the manufacturer.

FAQ:

1. Can an automatic filling machine be used for both liquid and viscous products?

Yes, automatic filling machines are versatile and can handle a wide range of viscosities, from low-viscosity liquids to highly viscous products, by adjusting parameters and using appropriate filling mechanisms.

2. What kind of training is required to operate an automatic filling machine?

Operators typically receive training on machine operation, control panel navigation, setup and changeover procedures, troubleshooting common issues, and safety protocols to ensure proper and efficient operation.

3. Can an automatic filling machine be used in a cleanroom environment?

Yes, there are automatic filling machines designed for cleanroom environments, featuring stainless steel construction, HEPA filtration, and other measures to maintain strict cleanliness standards.

4. How does an automatic filling machine prevent product spillage or overflow?

Automatic filling machines are equipped with sensors or volume control mechanisms to detect fill levels, ensuring precise and accurate filling, preventing spillage or overflow.

5. Can an automatic filling machine be connected to other packaging equipment?

Yes, automatic filling machines can be integrated with other packaging equipment, suchas capping machines, labeling machines, or sealing machines, to create a complete automated packaging line.