Aerosol Filling Machine Overview

Speed: 3600-4200 cans/hour (can be customized according to your needs)

Can Type:1 inch tinplate and aluminum can

Propellant Type: LPG, DME, N₂, CO₂, R134a, etc

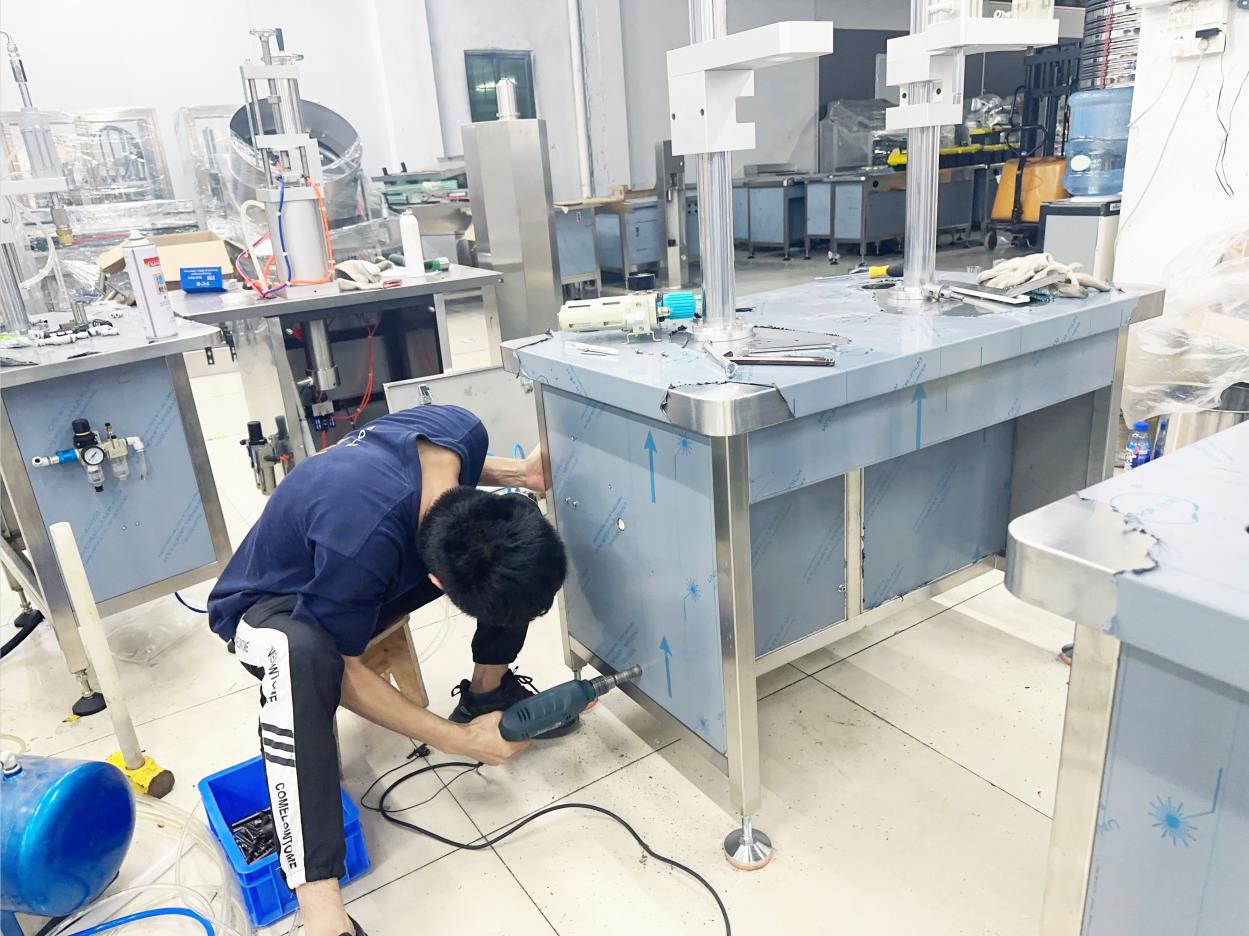

Core components: Can feeding machine , Liquid filling machine , Gas filling machine, Valve insert , Air piston pump , Weight checking machine , Packing table.

Recommended Products

FAQ on common issues with aerosol filling machines:

1. What is the propellant type of aerosol filling machine :

The type of propellant used in the aerosol product (e.g., LPG, DME, N₂, CO₂, R134a, etc)

2. What is the terminal products of aerosol filling machine?

It is suitable for various types such as deodorants, hair sprays, and air fresheners,oil spray , snow spray ,etc.

3.What is the application fields of aerosol filling machine?

It is suitable for various fields such as house care ,car care , personal care and chemical industries.

4. Can the machine handle different sizes of aerosol cans?

Yes, our aerosol filling machines are designed to be compatible with multiple can sizes.

5. What if the filling quantity is inaccurate?

Check the settings and components of the filling system for possible issues.

6. Does the machine have safety features?

Most machines are equipped with safety features to ensure operator safety.

Why Choose WEJING

Brand advantages:

1. Provide customers with comprehensive technical support and services.

2. Provide customers with free technical training .

3. Provide sincere after-sales service with a response time of no more than 12 hours.

4. Factory direct sales, suffcient supply of goods, reducingintermediate sales links.

Service advantages:

1. Professional Quality: 10 years of quality assurance, trustworthy.

2. Service Guarantee: Free pre-sales sampling, on-site inspection, convenient forusers to use; After sales warranty for two years, mandatory repair for any damage,life long maintenance.

3. Technical Service: With years of accumulation of filling packaging machinery technology and experience, we have numerous R&D talents and strong.

Technical advantages:

1. Precision manufacturing: Wejing Machinery uses advanced processes for highly accurate products.

2. Expert R & D team: Skilled engineers develop innovative and custom - made machinery.

3. Quality materials: Utilizes top - grade materials for durability and long - term performance.

Certificate Advantages:

1. Quality Assurance: With ISO9001, Wejing Machinery ensures consistent high - quality products.

2. Safety Compliance: The CE certificate guarantees the safety of Wejing Machinery for users.

3. Customer Trust: Enhance customer confidence in Wejing's products and services with CE & ISO9001.

Real Reviews From Real Customers

Positive reviews from African clients

The machine has gained recognition from Australian customers

News About Aerosol Filling Machine For WEJING

-

Aerosol filling machines are essential for precise, efficient production of countless products. Discover the top 10 global manufacturers leading the industry with innovative technology, reliable equipment, and comprehensive support. Find the perfect aerosol filling solution for your cosmetic, pharmaceutical, or industrial needs.Blog

Aerosol filling machines are essential for precise, efficient production of countless products. Discover the top 10 global manufacturers leading the industry with innovative technology, reliable equipment, and comprehensive support. Find the perfect aerosol filling solution for your cosmetic, pharmaceutical, or industrial needs.Blog -

Aerosol propellants,as the core element of an aerosol system, play a vital role in product spraying and dispersion. This guide aims to provide you with a comprehensive understanding of aerosol propellants, including how they work, their types, environmental impacts, and future development trends.Blog

Aerosol propellants,as the core element of an aerosol system, play a vital role in product spraying and dispersion. This guide aims to provide you with a comprehensive understanding of aerosol propellants, including how they work, their types, environmental impacts, and future development trends.Blog -

In today’s fast-paced food and beverage industry, efficiency and accuracy are paramount. Manufacturers are constantly seeking innovative solutions to streamline their production processes and ensure product quality. One such innovation that has become increasingly popular is the semi auto aerosol fiBlog

In today’s fast-paced food and beverage industry, efficiency and accuracy are paramount. Manufacturers are constantly seeking innovative solutions to streamline their production processes and ensure product quality. One such innovation that has become increasingly popular is the semi auto aerosol fiBlog