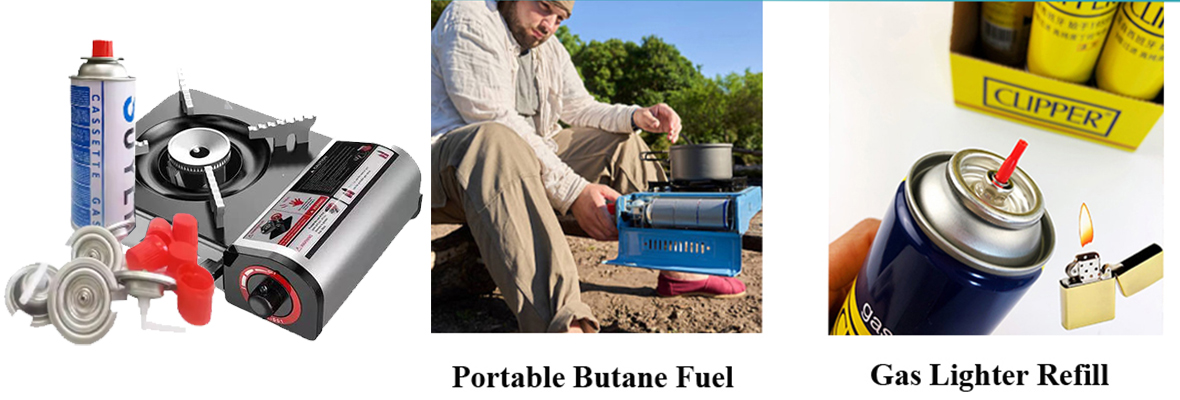

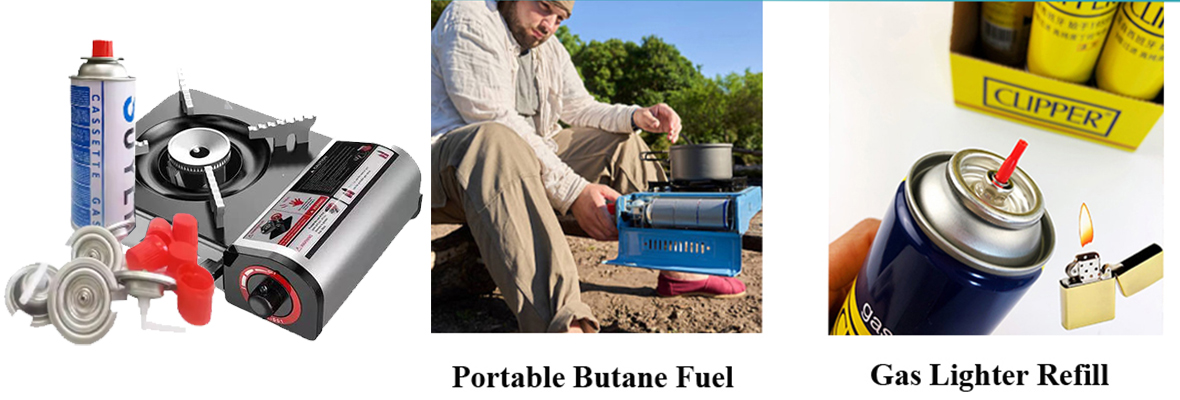

1. Introduction to Cartridge Gas

Cartridge gas, typically referring to fuel for portable cartridge stoves, primarily consists of butane stored in liquid form within specialized canisters. It serves as a common portable energy source for outdoor activities.

The core characteristics of canister gas lie in its portability and safety design. It primarily uses filled butane gas as fuel (some canisters can also use liquefied petroleum gas, etc.), heating directly through physical means. It is widely used in outdoor activities such as camping and hiking. Modern compliant canisters are equipped with high-temperature automatic pressure relief valves. When the ambient temperature is too high or the internal pressure is abnormal, they actively release pressure, effectively avoiding explosion risks and enhancing safety during outdoor use.

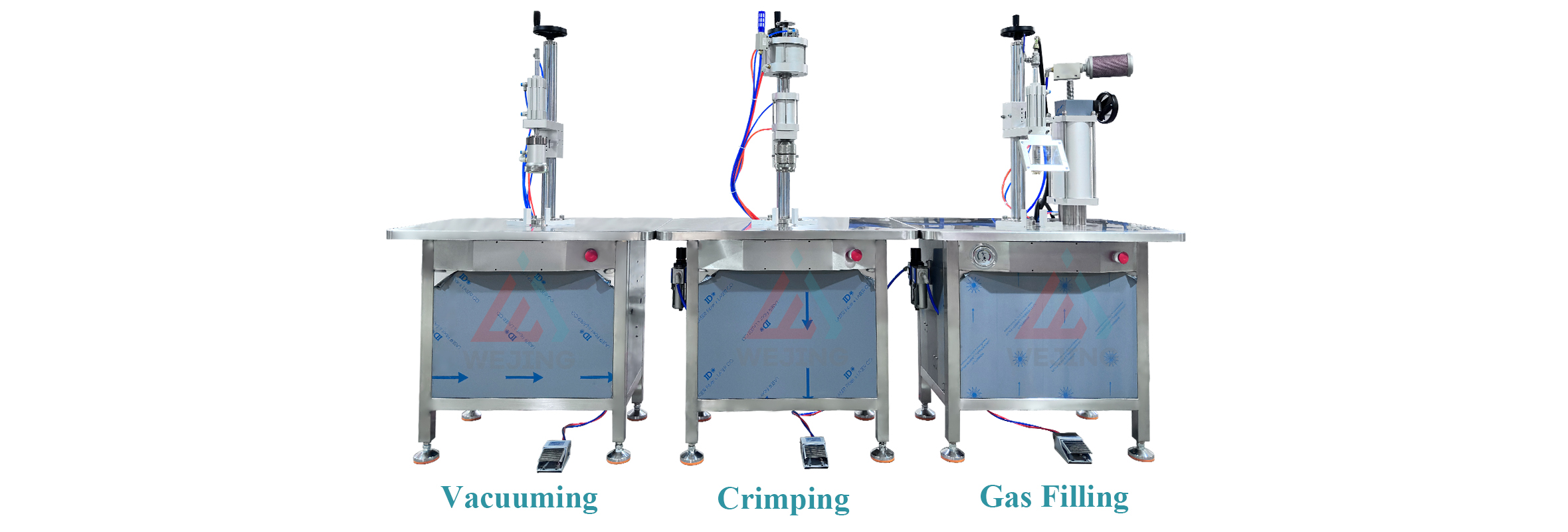

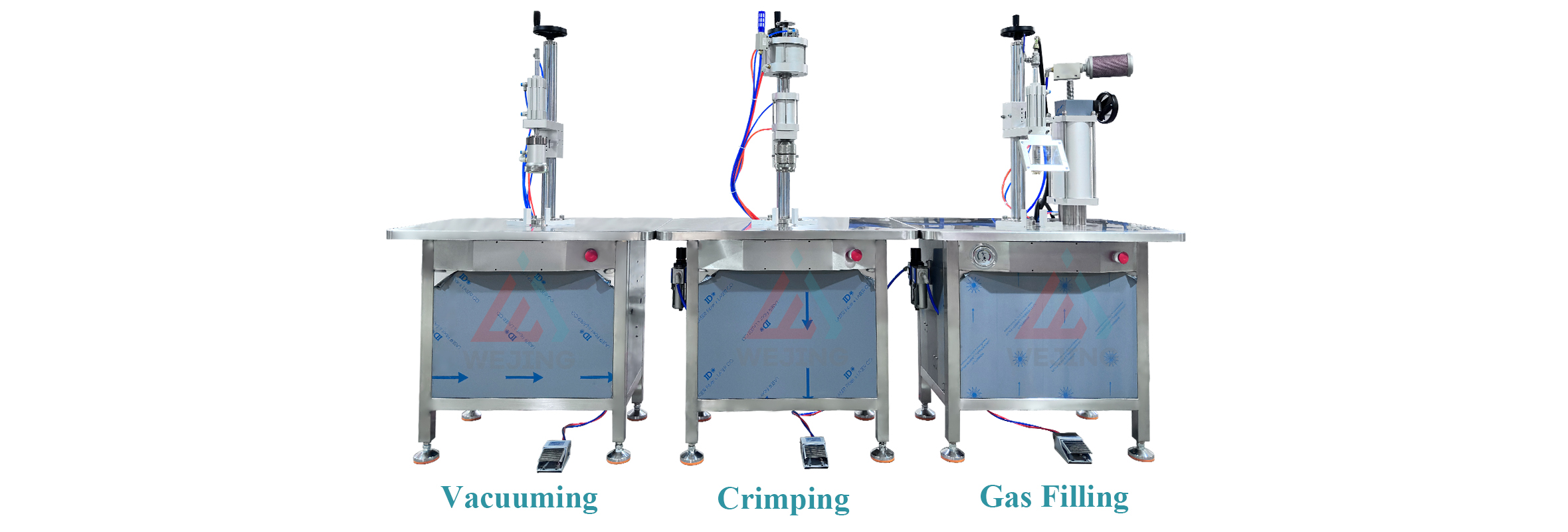

2. Filling Production Process

Cartridge gas consists of aerosol cans, valves, protective caps, and butane gas, with its production completed using specialized equipment. The production flow is as follows: Can feeding → valve inserting → vacuum → sealing → gas filling → weight checking → water bath leak testing → capping → coding → packing and shipping.

3. Equipment Introduction and Selection

Cartridge gas filling equipment is categorized by production scale into small-scale and large-scale systems. Our company offers various product lines and model configurations to meet diverse customer output requirements.

(1)  Semi-Automatic Butane Gas Filling Machine

Semi-Automatic Butane Gas Filling Machine

For startups, small workshops, or low-volume production enterprises; We recommend this semi-automatic cartridge aerosol filling machine, which consists of a vacuum pump, sealing machine, and gas filling unit (including booster pump). It offers high filling accuracy and excellent stability. Filling capacity: 30-500ml (customizable). Filling speed: 600-1200 cans per minute. Ideal for entrepreneurial small and medium-sized aerosol manufacturers.

1 | Capacity | 600-1200 cans/ hour, depending on filing volume |

2 | Liquid filling capacity | 30-500ml(can be adjustable) |

3 | Gas filling capacity | 30-500ml(can be adjustable) |

4 | Filling accuracy | ≤±1% |

5 | Applicable aerosol can diameter | 40-70mm |

6 | Suitable aerosol can height | 70-300mm |

7 | Air source | 0.5-0.6Mpa |

(2)Automatic Cartridge Gas Filling Production Line

For manufacturers with stable sales channels and large-scale production, we recommend the automatic cartridge gas filling production line. This line comprises a bottle sorting machine, automatic valve applicator, turntable vacuum sealing and gas filling machine, automatic weighing system, water bath leak detection, automatic capping machine, coding machine, and conveyor belt. All processes are mechanized, significantly reducing labor requirements and making it ideal for aerosol manufacturers with ultra-high-volume production.

Note: Could customizable based on specific customer requirements.

1 | Filling capacity | 60-80ans/min |

2 | Liquid filling volume | 30-1200 ml ( can be customized) |

3 | Gas filling volume | 30-1200ml( can be customized) |

4 | Filling accuracy | ≤±1% |

5 | Applicable cans diameter | 35 - 70mm( can be customized) |

6 | Applicable cans height (mm) | 80 - 300mm( can be customized) |

7 | Applicable valve | 1 inch |

8 | Working pressure | 0.6 - 0.8Mpa |

9 | Max gas consumption | 3m3/min |

10 | Material | SS304 ( some parts can be SS316) |

11 | Power | 50KW |

12 | Warranty | 2 years |