Introduction

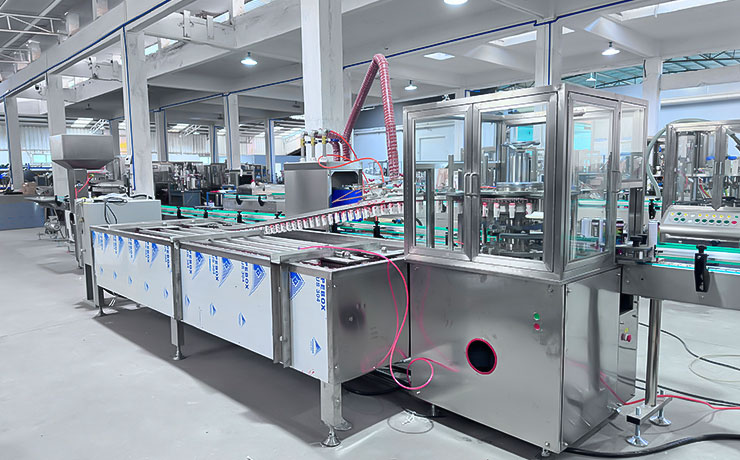

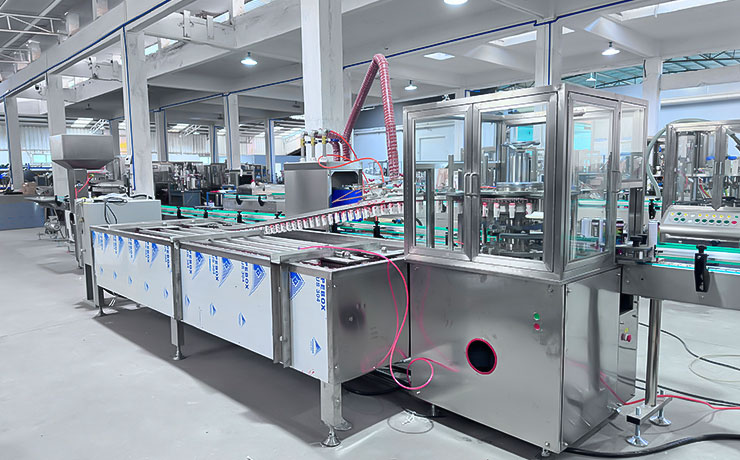

In the global aerosol market, the ability to rapidly respond to diverse demands through production capacity is becoming the key to brand competitiveness. A Mexican air freshener manufacturer specializing in high-end home environments faced this challenge: how to achieve flexible, efficient production of multiple product categories and specifications while ensuring quality and stability? After rigorous global evaluation, they ultimately partnered with Guangzhou Weijing Intelligent Equipment Co., Ltd. to implement a meticulously designed QGJ-70 fully automated aerosol filling line. This production line not only guarantees output capacity but also serves as an intelligent solution engineered for flexibility and future growth.

1. Core Client Requirements

As an industry innovator with a diverse and rapidly evolving product line, the client's primary need transcends mere scale expansion. They sought a production system capable of supporting their business model:

(1) Ultimate Production Flexibility

Frequent, rapid switching between products of varying capacities, fragrances, and formulations demands exceptional equipment versatility and changeover efficiency.

(2) Exceptional Stability and Quality Control

Rigorous standards for filling precision and seal reliability necessitate equipment maintaining stability during prolonged continuous operation to ensure batch-to-batch consistency.

(3) Maximized Investment Efficiency

Seeking optimal balance between initial investment and long-term operational costs while meeting defined capacity targets (70 cans/minute).

(4) Workshop Layout and Process Optimization

The production line must seamlessly integrate into existing facilities while optimizing material and personnel flow to enhance overall operational efficiency.

2. Solution

Weijing Intelligent tailored the QGJ-70 fully automated filling production line for the client. Its core advantages include:

(1) Flexible Production Design

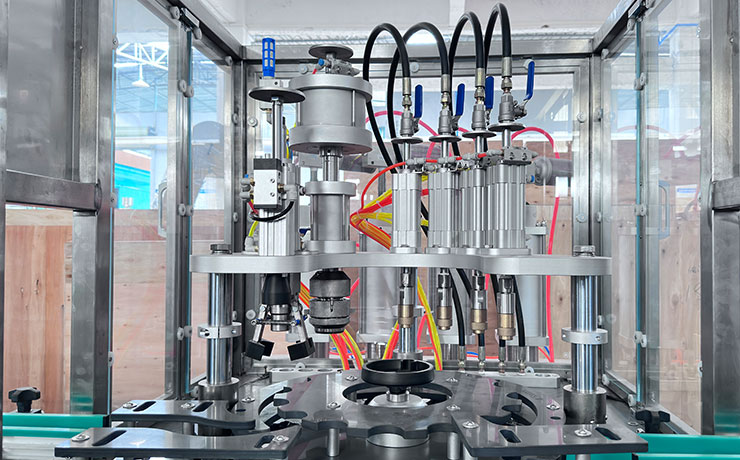

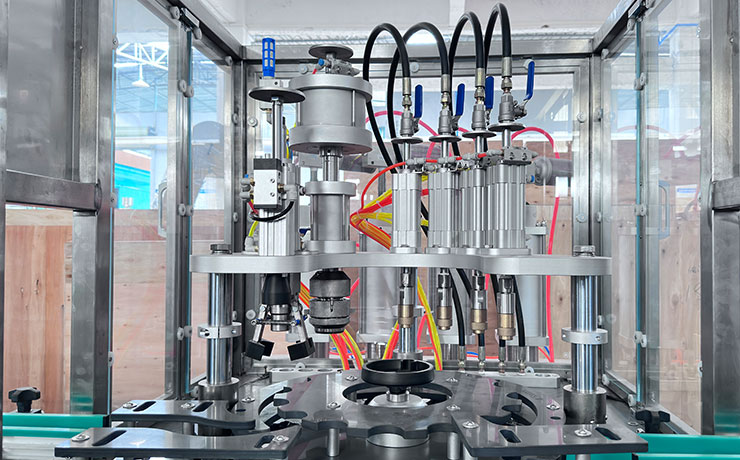

The entire line employs a fully modular design, with each functional unit—from liquid filling and valve installation to gas filling and inspection—being independent and configurable. Customers can configure the line according to current product requirements and easily add, remove, or upgrade modules like building blocks as business evolves—without replacing the entire line. This perfectly supports small-batch, high-frequency production while minimizing changeover time and costs.

(2) Stable Quality Assurance

l High-precision filling within ±1% ensures product consistency

l Integrated inspection stages like water bath leak detection guarantee 100% pass rate

l ISO quality management system implemented throughout equipment manufacturing

(3) Future-Ready Intelligent Design

l Reserved equipment interfaces support future functional expansion

l Energy-optimized design reduces long-term operational costs

l Remote operation and maintenance support enables intelligent servicing

(4) Technical Highlights

l Production Speed: 60-70 cans/minute (adjustable)

l Applicable Containers: Diameter 35-70mm, Height 85-310mm

l Filling Accuracy: ±1%

l Equipment Layout: Customized U-shaped design

(5) Customer Value Realization

l Production changeover time reduced by 60%

l Space utilization improved by 35%

l Operational labor costs reduced by 30%

l Product defect rate reduced to below 0.1%

3. Expert Perspective

“True smart manufacturing pursues not merely high speed, but precisely matched flexible production. Weijing's solution enables customers to achieve maximum comprehensive benefits at an optimized rhythm of 70 cans per minute.”

4. Project Outlook

This production line will serve as the core foundation for the client's capacity expansion over the next 3-5 years, supporting continuous innovation across their product portfolio. Wejing Intelligent will continue providing comprehensive technical support to help the client maintain a competitive edge in the global market.

5. About Us

Guangzhou Wejing Intelligent Equipment Co., Ltd. specializes in delivering intelligent filling solutions for global manufacturing enterprises. Leveraging extensive industry expertise and technological innovation capabilities, we have assisted clients in over 30 countries and regions in achieving production upgrades.