1. Edible Oil Spray

Edible oil spray canisters are products where edible oil and propellant are filled into a container, allowing direct spraying onto food during use. Common applications include: grilling, baking, food coloring, and wok-frying. With growing emphasis on low-fat, healthy living, precise oil control and reduced fat intake have become widespread in daily life.

The BOV aerosol cooking oil represents an innovative kitchen oil packaging solution. Its canister features an independent flexible food-grade pouch containing the oil, while compressed air or nitrogen fills the space between the pouch and the canister body. During use, gas pressure evenly compresses the pouch, forcing the oil through a specialized valve to form a uniform, fine mist or stream.

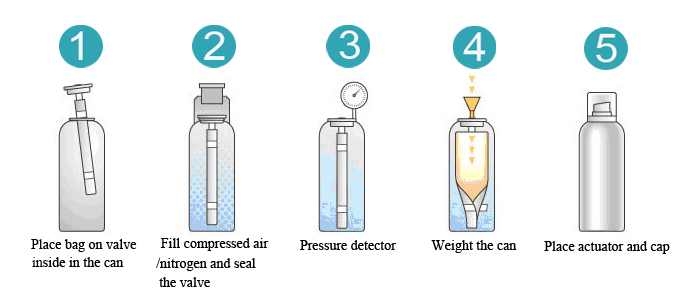

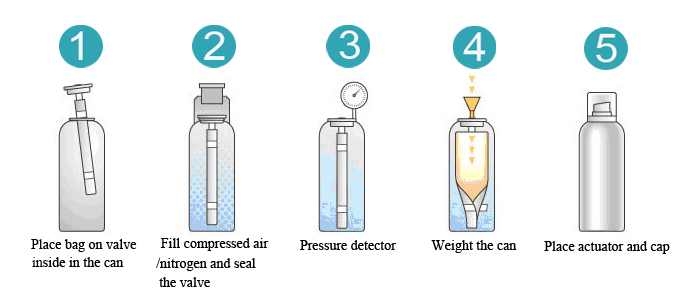

2. Filling Production Process

① Empty Can Feeding: Operators manually or automatically place pre-installed empty cans onto the equipment workbench.

② Pressurization & Sealing: Compressed air or nitrogen is injected into the space between the valve and can wall. The valve and can opening are then sealed.

③ Filling: A pre-prepared shaving gel base is quantitatively dispensed into the bladder via an independent filling head. The liquid and gas remain completely separated.

④ Pressure Testing: The aerosol can undergoes pressure testing.

⑤ Valve stem cleaning: Clean the valve stems of filled aerosol cans.

⑥ Fixing press:Install press.

⑦ Capping: Install outer caps.

3. Equipment Introduction and Selection

For startups, we recommend compact fully automated equipment. This solution offers not only cost-effectiveness and labor savings through high automation, but also a modular design that facilitates future upgrades or downgrades. It seamlessly adapts to product changes or increased production volumes, enabling easy product modifications or assembly line operations.

For manufacturing enterprises, we recommend fully automated assembly line products. These significantly enhance operational efficiency while reducing labor requirements.

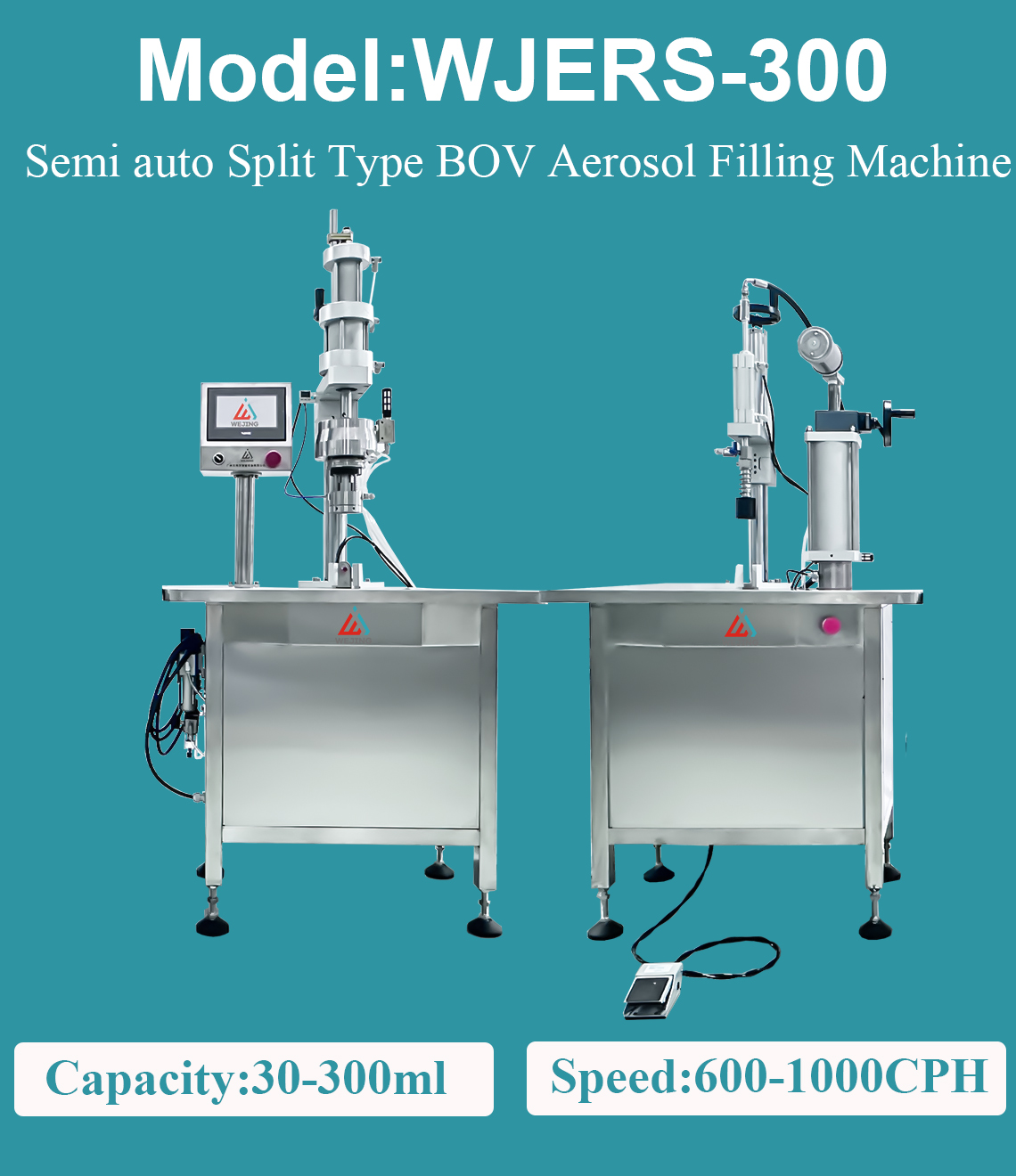

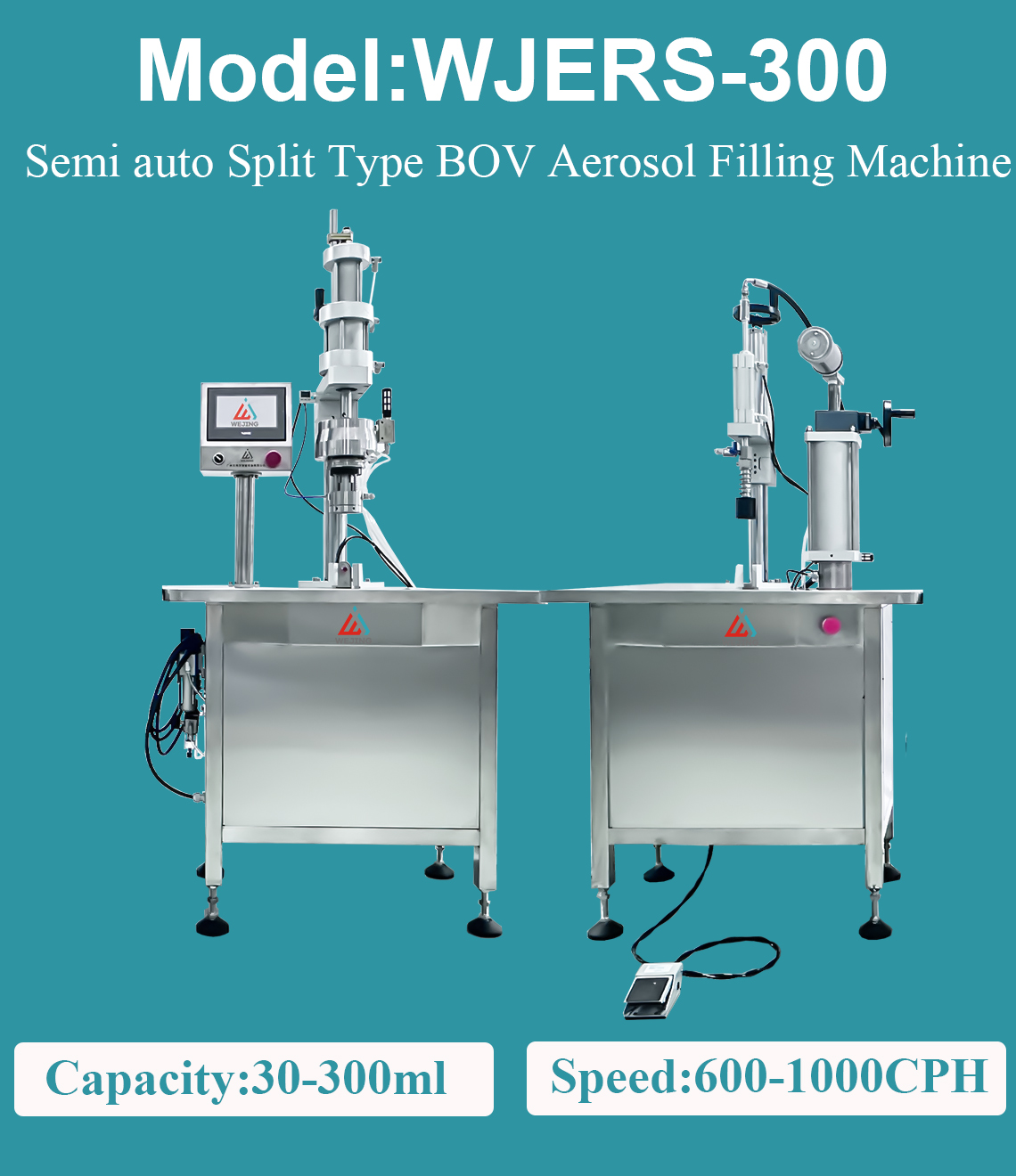

(1)  Semi-Automatic Binary Aerosol Filling Machine (Speed: 600-1000cans per hour)

Semi-Automatic Binary Aerosol Filling Machine (Speed: 600-1000cans per hour)

Lowest investment with high flexibility. Requires manual can loading/unloading, suitable for R&D, small-batch trials, startups, or small factories. Features higher integrated functionality.

|

|

The WJERS-300 Semi-Automatic Dual-Function Aerosol Filling Machine consists of an integrated gas-charging and sealing unit and a filling unit. | The WJER-650Semi-AutomaticBOVAerosol Filling Machine integrates the gas-charging & sealing head,liquid filling head,pressure testing and valve term cleaning heas onto a single workbench. |

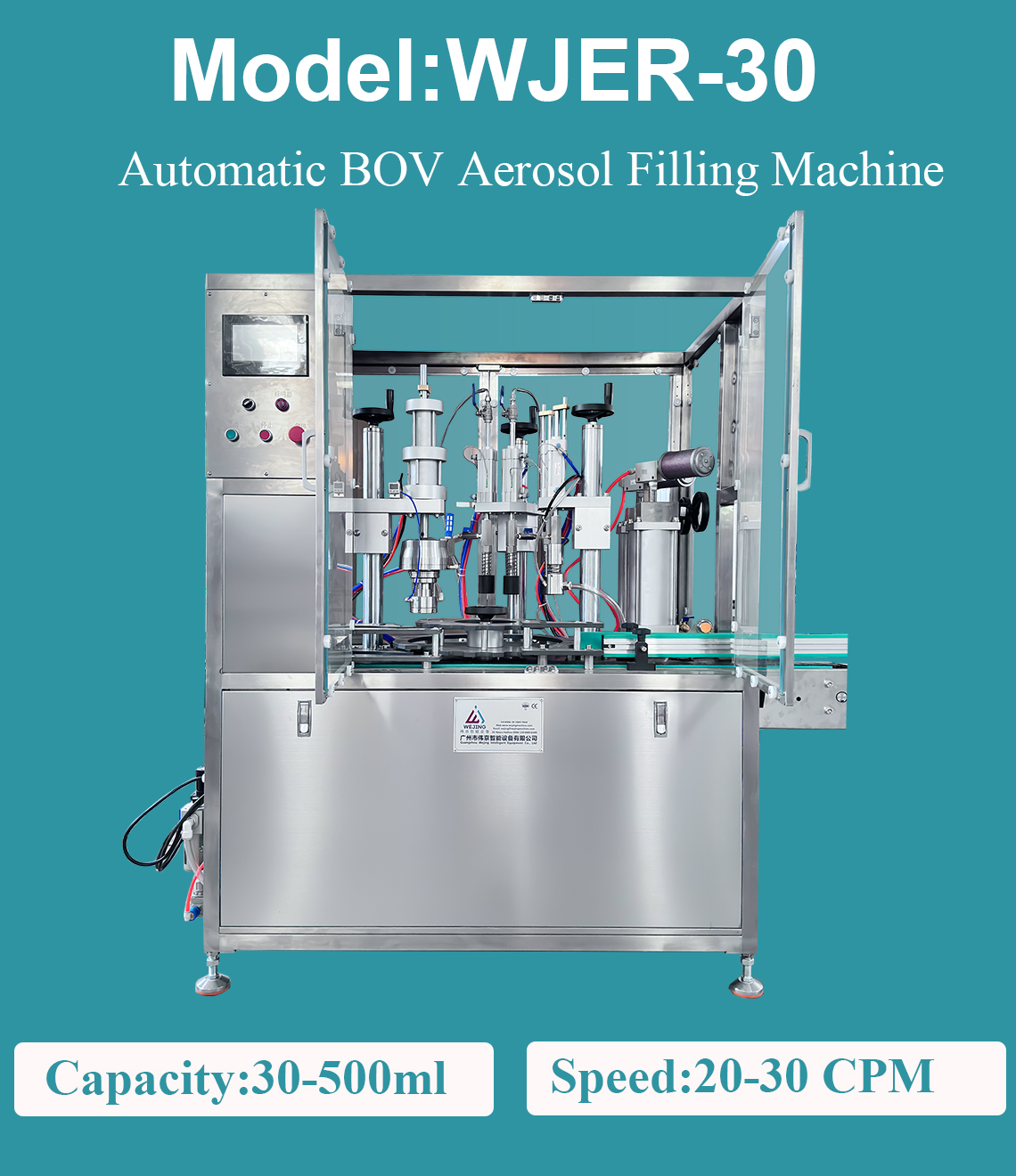

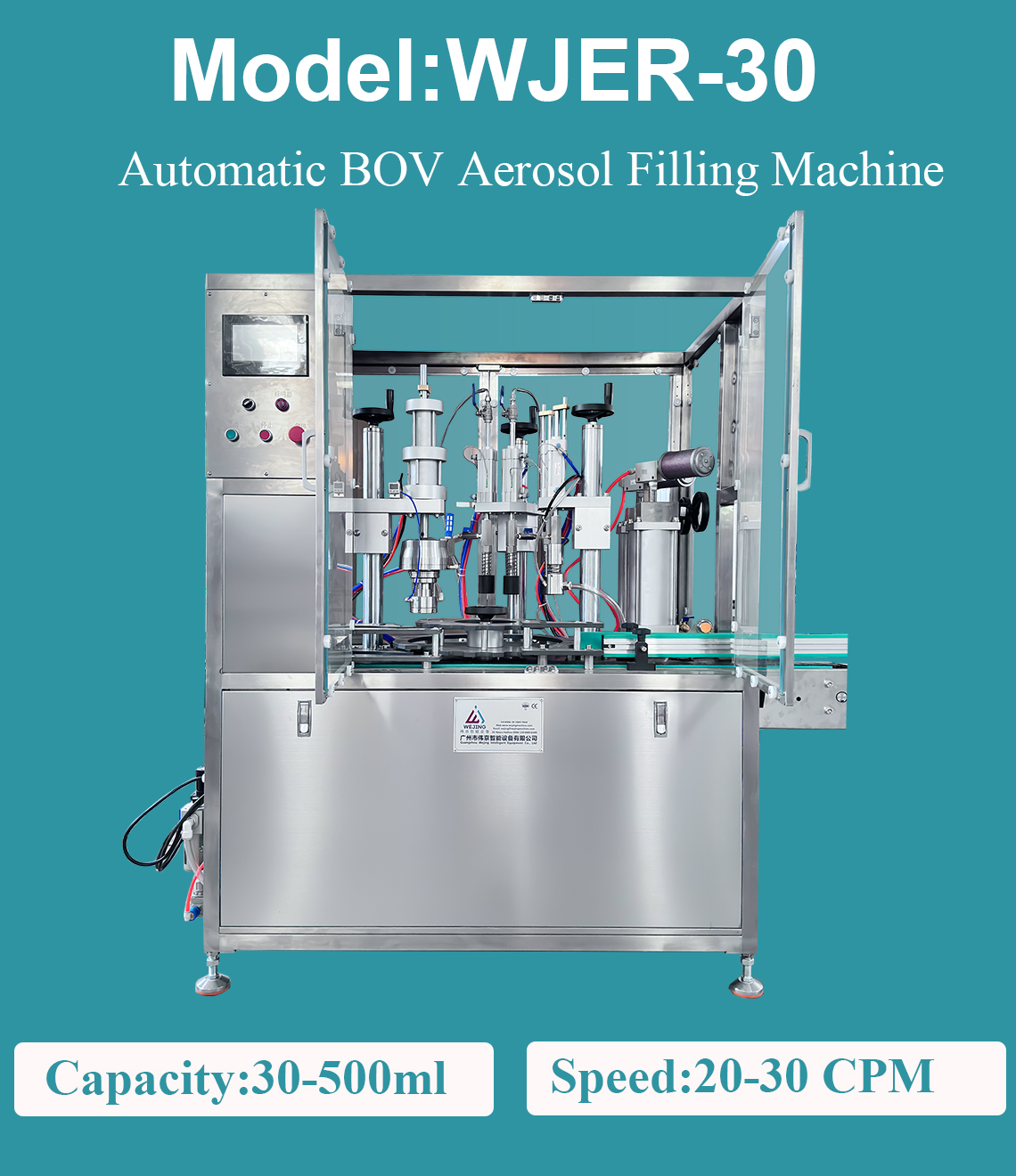

(2)  Compact Automatic Dual-Head Filling Machine (Speed: 20-30cans per min)

Compact Automatic Dual-Head Filling Machine (Speed: 20-30cans per min)

Features automated upgrades with integrated online pressure monitoring and cleaning systems to enhance quality control and operational efficiency. Ideal for small to medium-scale production runs, offering an excellent cost-performance ratio.

(3)  WJER-60 Automatic BOV Filling Machine (Speed: 50-60 cans per minute)

WJER-60 Automatic BOV Filling Machine (Speed: 50-60 cans per minute)

Standard fully automated production line. Multi-station parallel operation significantly enhances speed and stability, with comprehensive in-line quality control functions. Suitable for continuous production in medium to large-scale operations.

(4)  WJER-80 Automatic BOV Filling Machine (Speed: 70-80 cans per minute)

WJER-80 Automatic BOV Filling Machine (Speed: 70-80 cans per minute)

Enhanced configuration, fastest production speed, and redundant design ensure stability. Designed specifically for large-scale production or clients seeking maximum efficiency.