Parameters

| Model:WJMX10 |

| 1 | Action flow | Automatic unloading, automatic filling, automatic sealing, finished product output |

| 2 | number of channels | 10(can be controlled individually) |

| 3 | Productivity | 13000PCS/H |

| 4 | Mask Bag Specifications | Width 80-165mm Length 90-225mm |

| 5 | Standard filling pump | Electronic gear pump |

| 6 | Filling accuracy | ±0.2g |

| 7 | Mains &Power | Mains:380V/50-60Hz Power:8KW |

| 8 | air pressure | 0.6Mpa 700L/min |

| 9 | Equipment size | 2800*1000*1750mm(Climbing belt not included) |

Product Details:

Mask bag discharge area

Large space for mask unloading area

High efficiency of mass production with 8 stations

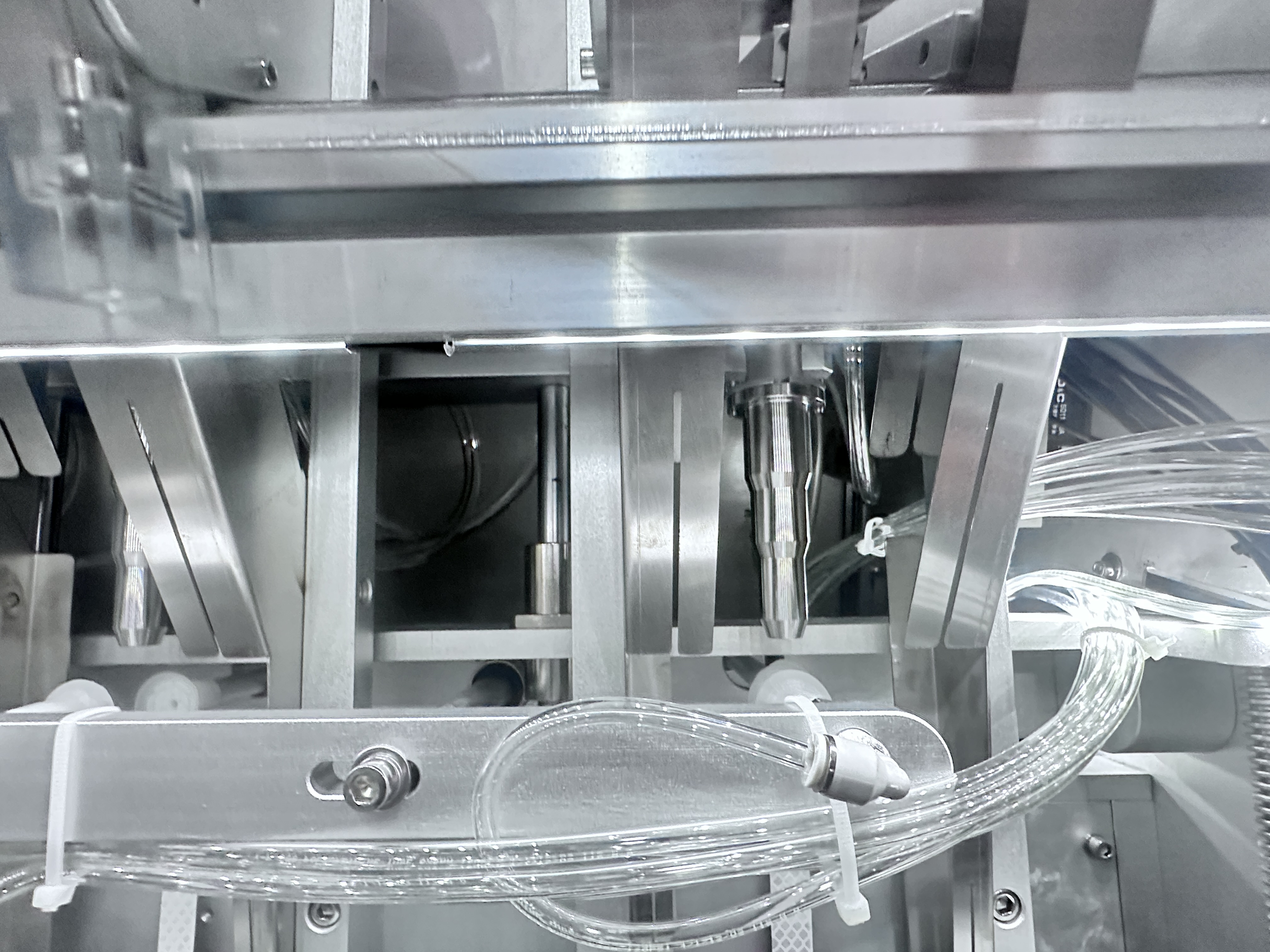

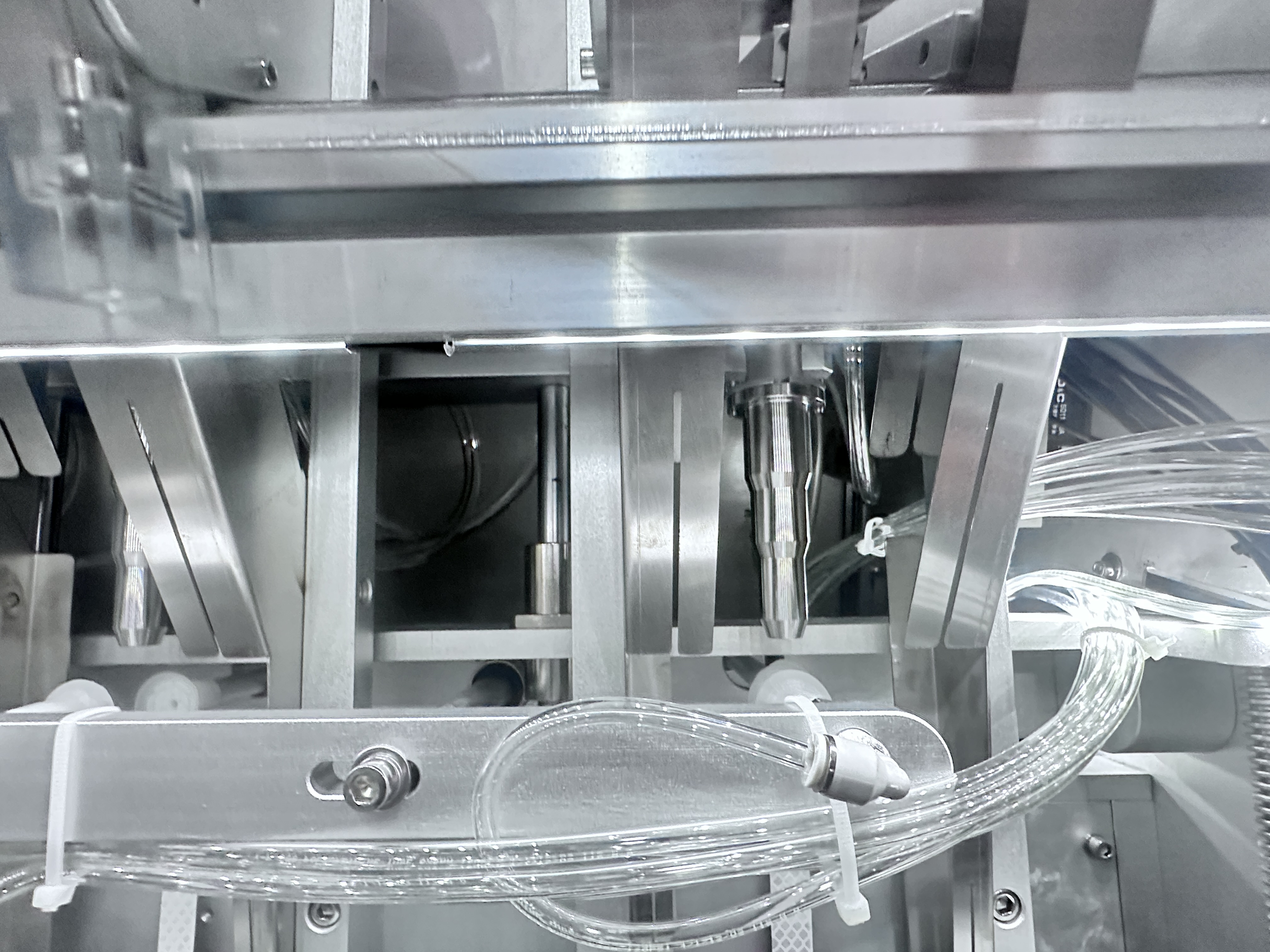

Bag opening and filling

Opening of the mask bag

Filling essence

Excess air is discharged from the bag after filling

Sealing and Coding

Heat sealing knife seals the mouth of the bag and prints the date of manufacture.

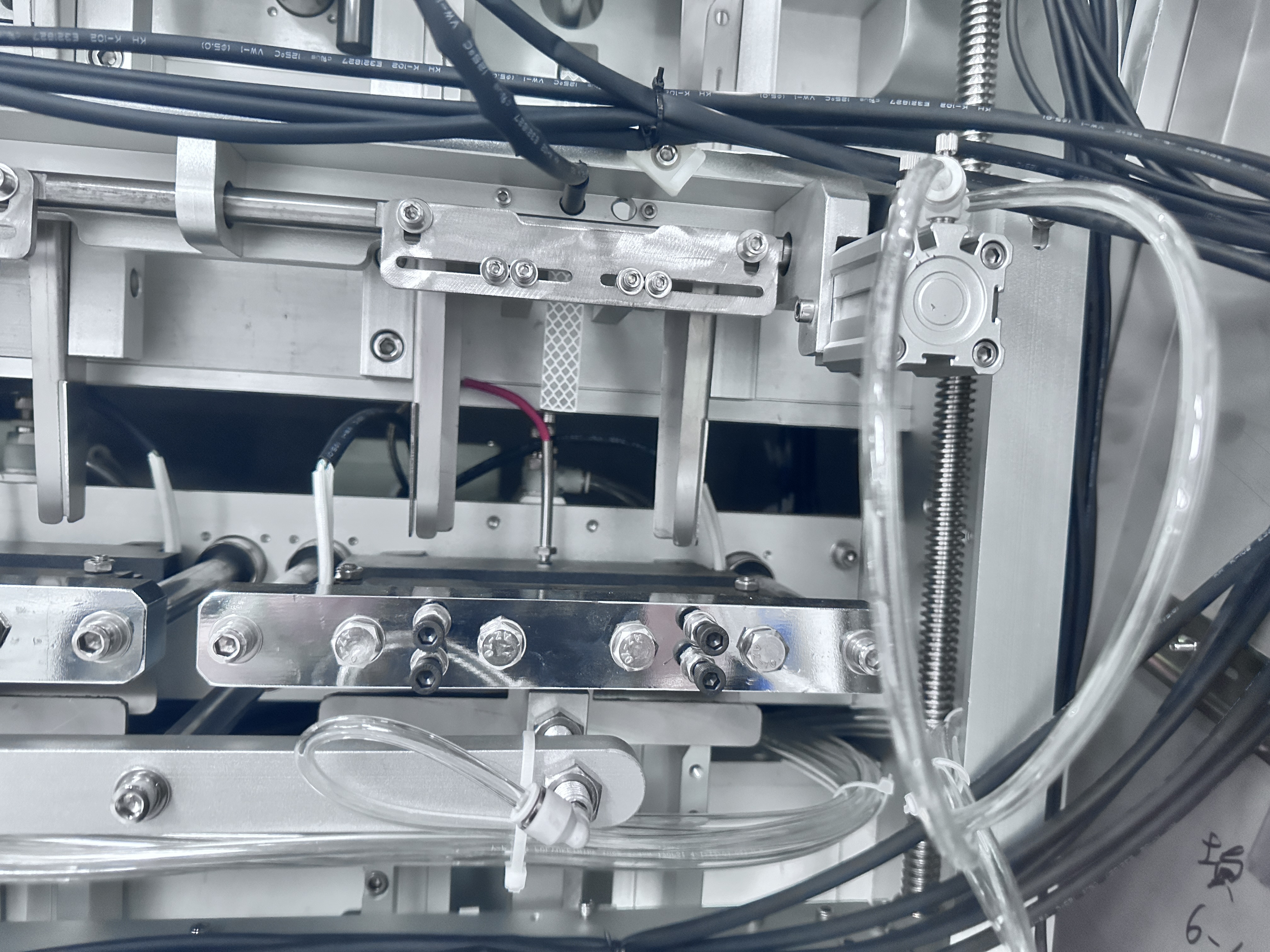

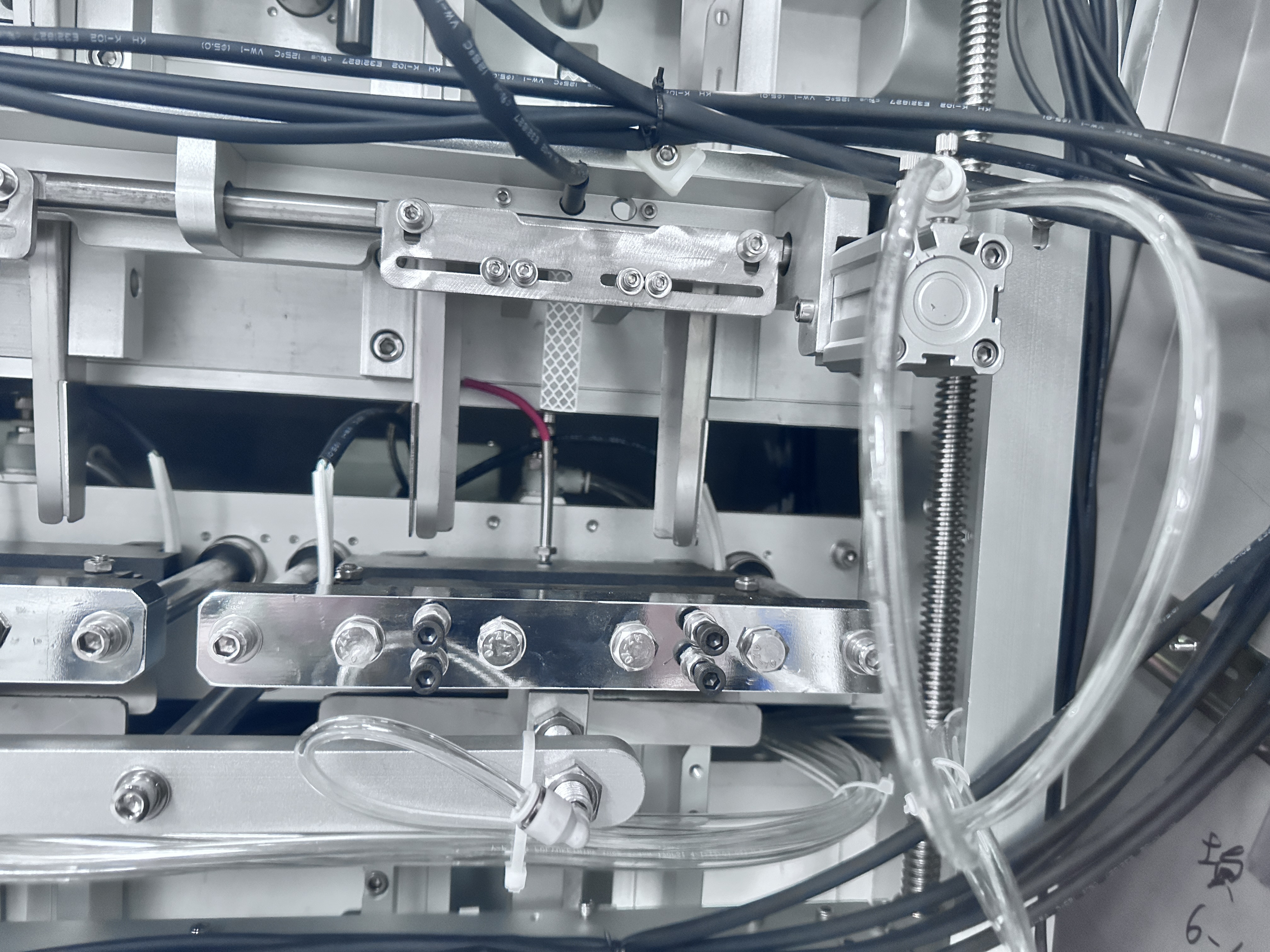

Precision magnetic pump

Multiple precise magnetic pump cleaningchannels can clean machinery accuratelyand quickly.

Adjustable width and height

Compatible with a variety of mask bags

Adjustable size can be switched by one key, no need to change the mold.

Vacuum pressure sensor

Fiber optic amplifier for high speed operation and stable bag opening

Product Advantages:

1. Plentiful Heads: The ten-head configuration permits concurrent filling, considerably accelerating the packaging rate of facial masks.

2. Precise Quantification: It accurately gauges the filling quantity, guaranteeing that every mask is furnished with the appropriate dosage of the product.

3. Sanitary: Constructed from materials that are effortlessly cleansed, upholding a top-notch hygienic milieu for cosmetic items.

4. Operator-Convenient: The straightforward operational panel empowers workers to swiftly master and handle the machine without difficulty.

5. Space-Efficient: Its condensed structure consumes less floor area in the factory whilst delivering excellent functionality.

Technical Features:

1. This machine is proficient in automatically discharging, filling, sealing, coding, and delivering products.

2. The components that make contact with the items are fabricated from 316 stainless steel, conforming to GMP norms.

3. When bags are lacking, neither the filling nor the sealing procedures will commence. The sealed bags will not stick together.

4. Operated by PLC + LED touch screen, it is convenient to configure the equipment parameters on the display, and the production capacity and error details are lucid.

5. Temperature regulation is effected via digital display.

6. The electrical and pneumatic parts are sourced from globally renowned brands.

FAQ:

1. Is this machine adaptable to diverse sizes of facial masks?

Yes, it can be modified to fit the various sizes of facial masks prevalently available in the market.

2. Is the machine simple to clean?

Yes. The components that make contact with the masks are typically made of 316 stainless steel, facilitating easy cleaning and maintaining hygiene.

3. Is the machine's operation intricate?

No. It is managed by PLC + LED touch screen, allowing for effortless parameter setting on the screen.

4. In what way is the temperature controlled?

Temperature control is realized via digital display, which is straightforward for accurate adjustment.

5. What about the caliber of the parts?

The electrical and pneumatic components are sourced from globally renowned brands, ensuring dependability and stability.