1. Introduction to Rust Inhibitors

Rust inhibitor, also known as rust-preventive aerosol, is a chemical agent used to protect metal surfaces by preventing or delaying oxidation and rust formation. It creates a barrier film on the metal surface, blocking contact between corrosive agents like moisture and oxygen and the metal, thereby effectively inhibiting rust generation and spread. It is widely applicable for inter-process rust prevention of steel, stainless steel, alloy steel components, and materials across numerous industries.

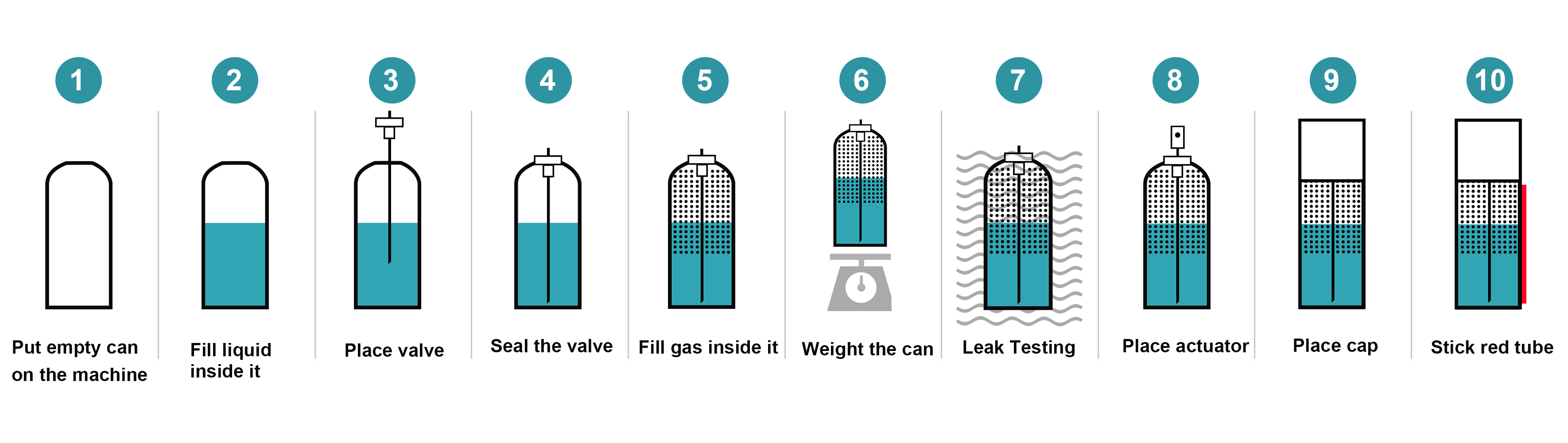

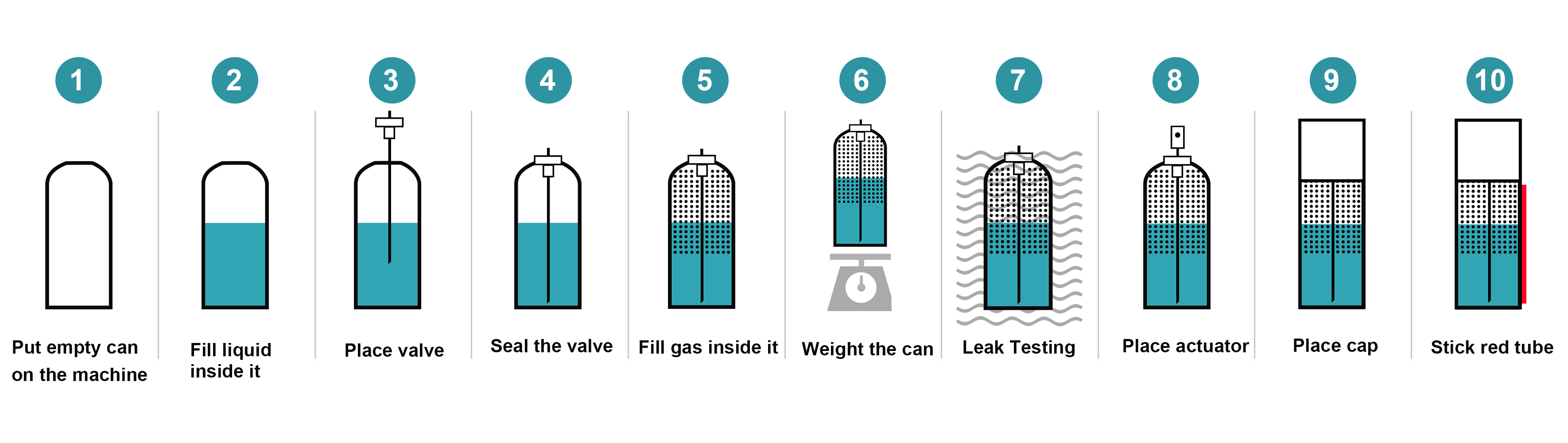

2. Filling Production Process

Rust-proof lubricant production technology is an aerosol technology, comprising aerosol cans, valves, nozzles, caps, base liquid, and propellant gas. The production process is completed using specialized equipment. The production flow is as follows: raw material production → raw material filling → valve inserting → sealing → propellant gas filling → weight checking → water bath leak testing → fixing nozzle →fixing cap → red tube sticking → coding → packaging and shipping.

3.Equipment Introduction and Selection

Rust-removing lubricant filling equipment is categorized into small-scale and large-scale production configurations based on operational capacity. Our company offers equipment with diverse product lines and model configurations to meet varying customer output requirements.

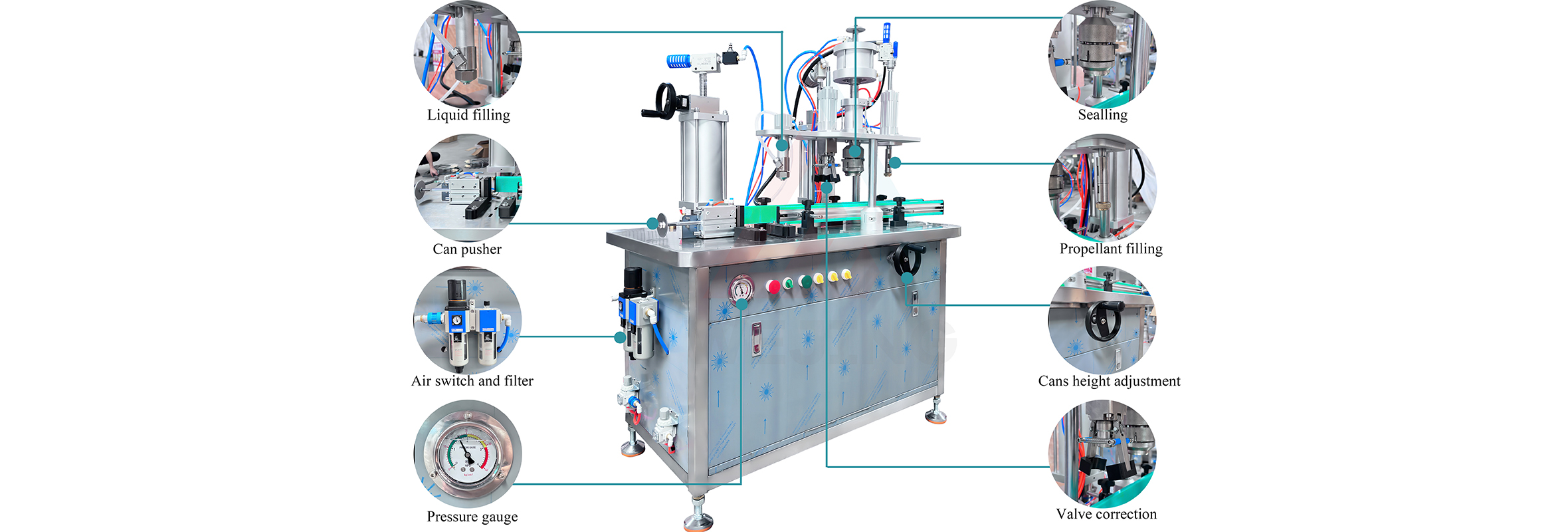

(1)  Semi-Automatic 4-in-1 Aerosol Filling Machine

Semi-Automatic 4-in-1 Aerosol Filling Machine

For start-ups or small-scale production enterprises with low output, we recommend the QGJV-20 Semi-Automatic 4-in-1 Aerosol Filling Machine.

This machine integrates liquid filling, valve positioning, sealing, and gas charging into one operation, simultaneously completing four processes with a single action. It saves labor and space while offering high efficiency, precision, and stability. Filling capacity: 30-500ml (customizable) Filling speed: 600-1200 cans per hour Ideal for entrepreneurial small-to-medium aerosol manufacturers.

1 | Capacity | 600-1200 cans/ hour, depending on filing volume |

2 | Liquid filling capacity | 30-500ml(can be adjustable) |

3 | Gas filling capacity | 30-500ml(can be adjustable) |

4 | Filling accuracy | ≤±1% |

5 | Applicable aerosol can diameter | 40-70mm |

6 | Suitable aerosol can height | 70-300mm |

7 | Air source | 0.5-0.6Mpa |

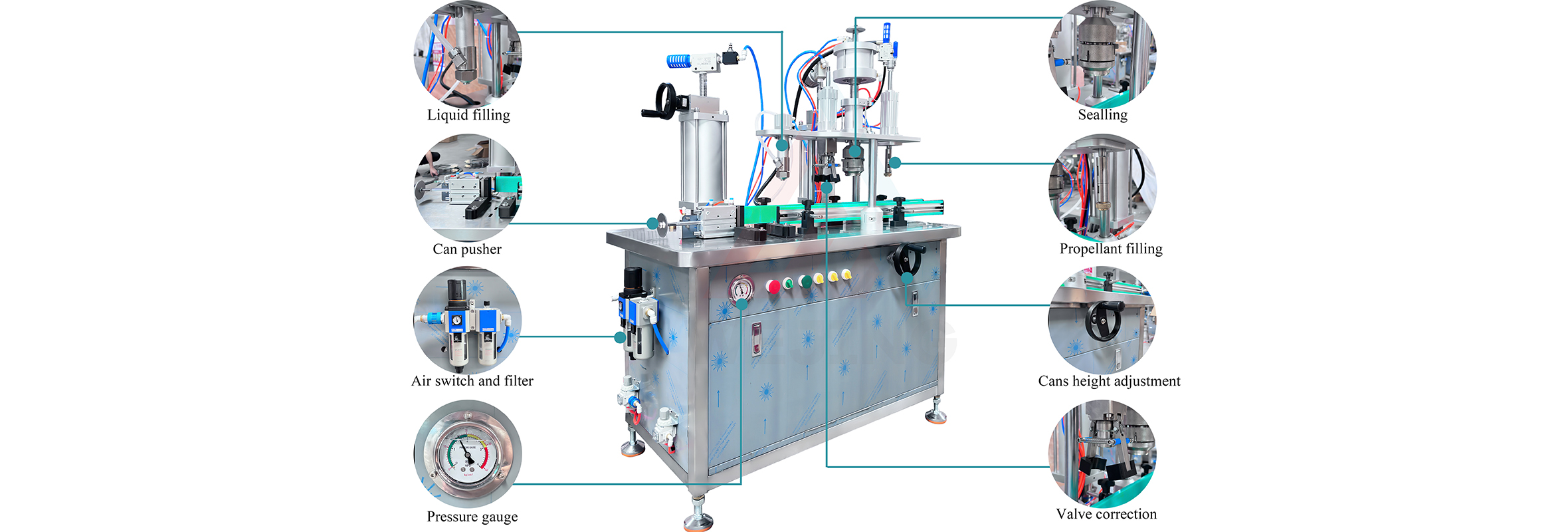

(2)  Automated Aerosol Filling Production Line

Automated Aerosol Filling Production Line

For enterprises with stable sales channels and large-scale production, we recommend the QGJ70 automated Lubricant aerosol filling production line.

This line comprises a turntable-type four-head liquid filler, turntable-type sealer, four-head gas charger, automatic valve applicator, automatic weighing system, automatic nozzle press, automatic cap press, coding machine, and conveyor belt. It can be integrated with a water bath leak detector. All processes are mechanized, significantly reducing labor requirements and making it ideal for aerosol manufacturers with ultra-high-volume production needs.

Note: Customization available based on specific client requirements.

1 | Filling capacity | 60-70cans/min |

2 | Liquid filling volume | 30-1200 ml ( can be customized) |

3 | Gas filling volume | 30-1200ml( can be customized) |

4 | Filling heads | 4 liquid heads & 4 gas filling head |

5 | Filling accuracy | ≤±1% |

6 | Applicable cans diameter | 35 - 70mm( can be customized) |

7 | Applicable cans height (mm) | 80 - 300mm( can be customized) |

8 | Applicable valve | 1 inch |

9 | Working pressure | 0.6 - 0.8Mpa |

10 | Max gas consumption | 5m3/min |

11 | Material | SS304 ( some parts can be SS316) |

12 | Power | 7.5KW |

13 | Warranty | 2 years |