1. Shaving Gel Introduction

Shaving gel is a gel-based product specifically designed for shaving and skin care. It softens facial hair, lubricates razor movement to reduce post-shave irritation, and enhances moisture retention in the shaved area.

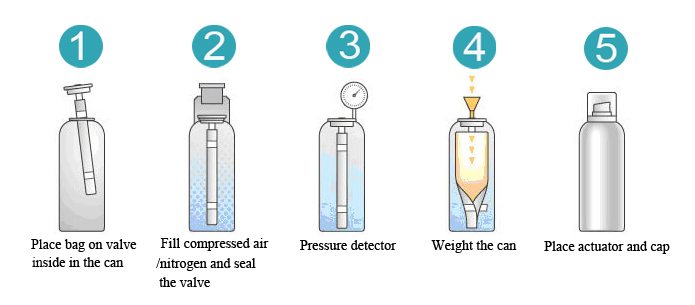

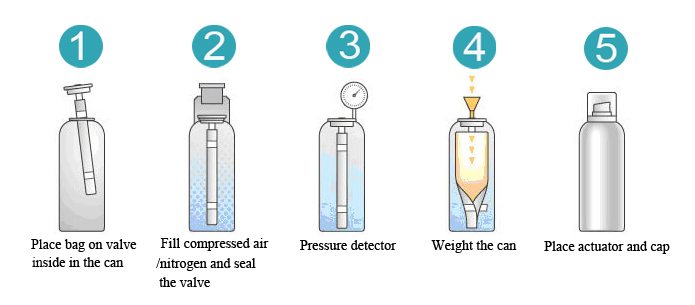

Shaving gel utilizes bag-on-valve aerosol packaging technology, characterized by an independent flexible pouch (typically polymer-based) housed within the can. The gel is contained within this pouch, while compressed air or nitrogen fills the space between the pouch and the can body. When the valve is pressed during use, external gas pressure compresses the pouch, smoothly dispensing the contents. As the gel matrix passes through a specialized foaming device at the valve tip, it mixes with air to instantly create a dense, fine lather.

2. Filling Production Process

① Empty Can Feeding: Operators manually or automatically place pre-installed empty cans onto the equipment workbench.

② Pressurization & Sealing: Compressed air or nitrogen is injected into the space between the valve and can wall. The valve and can opening are then sealed.

③ Filling: A pre-prepared shaving gel base is quantitatively dispensed into the bladder via an independent filling head. The liquid and gas remain completely separated.

④ Pressure Testing: The aerosol can undergoes pressure testing.

⑤ Valve stem cleaning: Clean the valve stems of filled aerosol cans.

⑥ Capping: Install outer caps.

3. Semi-Automatic Shaving Gel BOV Aerosol Filling Machine

We recommend the WJER-650 semi-automatic shaving gel BOV aerosol filling machine. This machine integrates compressed air (or N₂) filling and sealing via touchscreen + PLC program control, followed by raw material filling. It is particularly suitable for shaving gel filling. Advantages include high speed, easy operation, accurate metering, excellent seal tightness, and freely adjustable gas pressure. Adjustments are convenient and versatile, accommodating diameters from 35-70mm without requiring mold changes. The machine also features a one-button tank cleaning function, significantly improving cleaning efficiency.

1 | Filling capacity (cans/min) | 10-15 cans/min |

2 | Liquid filling volume (ml) | 30-650ml |

3 | Gas filling accuracy | ±0.03Mpa |

4 | Liquid filling accuracy | ≤±1% |

5 | Applicable cans diameter (mm) | 35-70 ( can be customized) |

6 | Applicable cans height (mm) | 70-330 ( can be customized) |

7 | Applicable valve (mm) | 25.4 (1 inch BOV) |

8 | Propellant | N2, compressed air |

9 | Max gas consumption (m3/min) | 1m3/min |

10 | Power (KW) | AC 220V/50HZ |

11 | Air source | 0.6-0.7Mpa |

12 | Dimensions | 1200×650×1670 mm |

13 | Weight | 255 kg |

4. Core Elements of the Production Plan

Raw Material Preparation: A uniform, stable shaving gel base must be prepared in advance.

Gas Supply: A stable, clean source of compressed air or nitrogen is required.

Environmental Control: The filling area should be kept clean to minimize contamination.

Personnel Operations: Semi-automated equipment requires 1-2 operators for loading, monitoring, and unloading.

5. The Difference Between Shaving Gel and Shaving Foam

Comparison Dimensions | Shaving Foam | Shaving Gel |

Core Structure | Standard aerosol package, with contents directly mixed with propellant. | Bag-on-aerosol package, where contents (inside the bag) are completely separated from propellant gas (outside the bag). |

Active Ingredients and Propellants | Foam base + liquefied gas propellant (e.g., propane-butane, dimethyl ether). | Gel/paste base + compressed air or nitrogen (non-liquefied). |

Mechanism of Action | Propellant vaporizes and expands, directly carrying and expanding the contents. | Gas compresses the flexible pouch, forcing the contents through a valve foaming device to create foam. |

Product Form | Instant foam, dispenses rich foam upon pressing. | Gel/paste instantly foams upon contact with air after extrusion. |

Safety | Pressurized can; propellant is typically flammable. | Uses only compressed gas, non-flammable, offering higher safety. |

Formulation and Skin Feel | Requires compatibility with propellant; may contain higher alcohol content, potentially offering a fresher or quicker-drying feel on skin. | Greater formulation flexibility allows more skincare ingredients, typically resulting in richer, gentler skin feel. |

Production Cost | Mature production equipment and processes, lower cost. | More complex packaging and equipment, higher initial investment. |

Environmental Sustainability | Traditional propellants may involve VOCs. | Uses air/nitrogen, more environmentally friendly. |