1. Carburetor Cleaner

Carbon deposits accumulating on components like the throttle body can cause issues such as unstable idling and increased fuel consumption. Carburetor cleaner effectively dissolves and removes these deposits, thoroughly cleaning relevant parts to restore fuel atomization and ensure uniform air-fuel mixture. This product is easy to use and cost-effective, making it widely applied in traditional vehicle maintenance to improve engine performance.

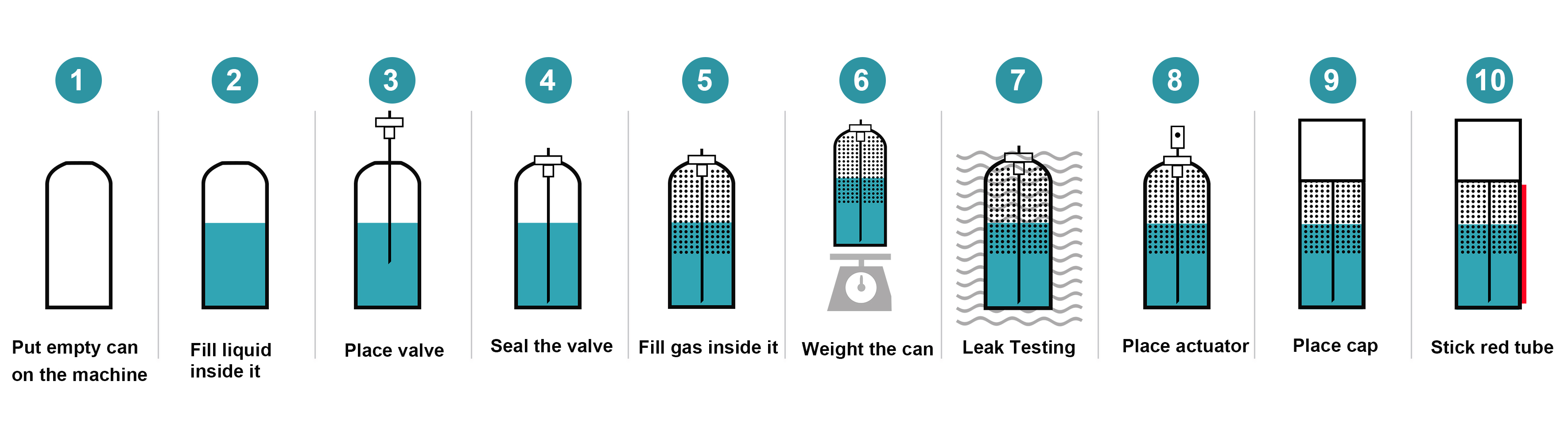

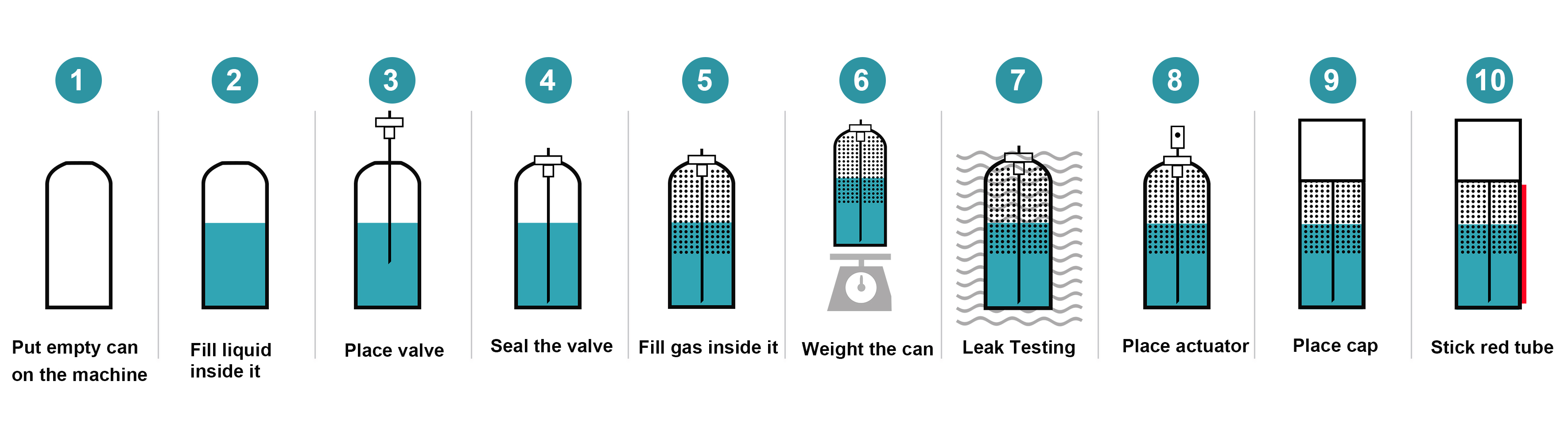

2. Filling Production Process

Carburetor cleaner production employs aerosol technology, comprising an aerosol can, valve, nozzle, cap, concentrate, and propellant gas. The manufacturing process is completed using specialized equipment and follows these steps: raw material production → raw material filling → valve inserting → sealing → propellant gas filling → weight checking → water bath leak testing → fixing nozzle →fixing cap → red tube sticking → coding → packaging and shipping.

3. Equipment Introduction and Selection

Carburetor cleaner filling equipment is categorized into small-scale and large-scale production based on operational capacity. Our company offers various product configurations and models to meet different customer output requirements.

(1)  Small-Scale Production Machinery (Startup/Pilot Production)

Small-Scale Production Machinery (Startup/Pilot Production)

Small-Scale Production Machinery (Startup/Pilot Production)

For startups, small workshops, or enterprises with low output volumes, we recommend the following three semi-automatic aerosol filling machines:

|

|

|

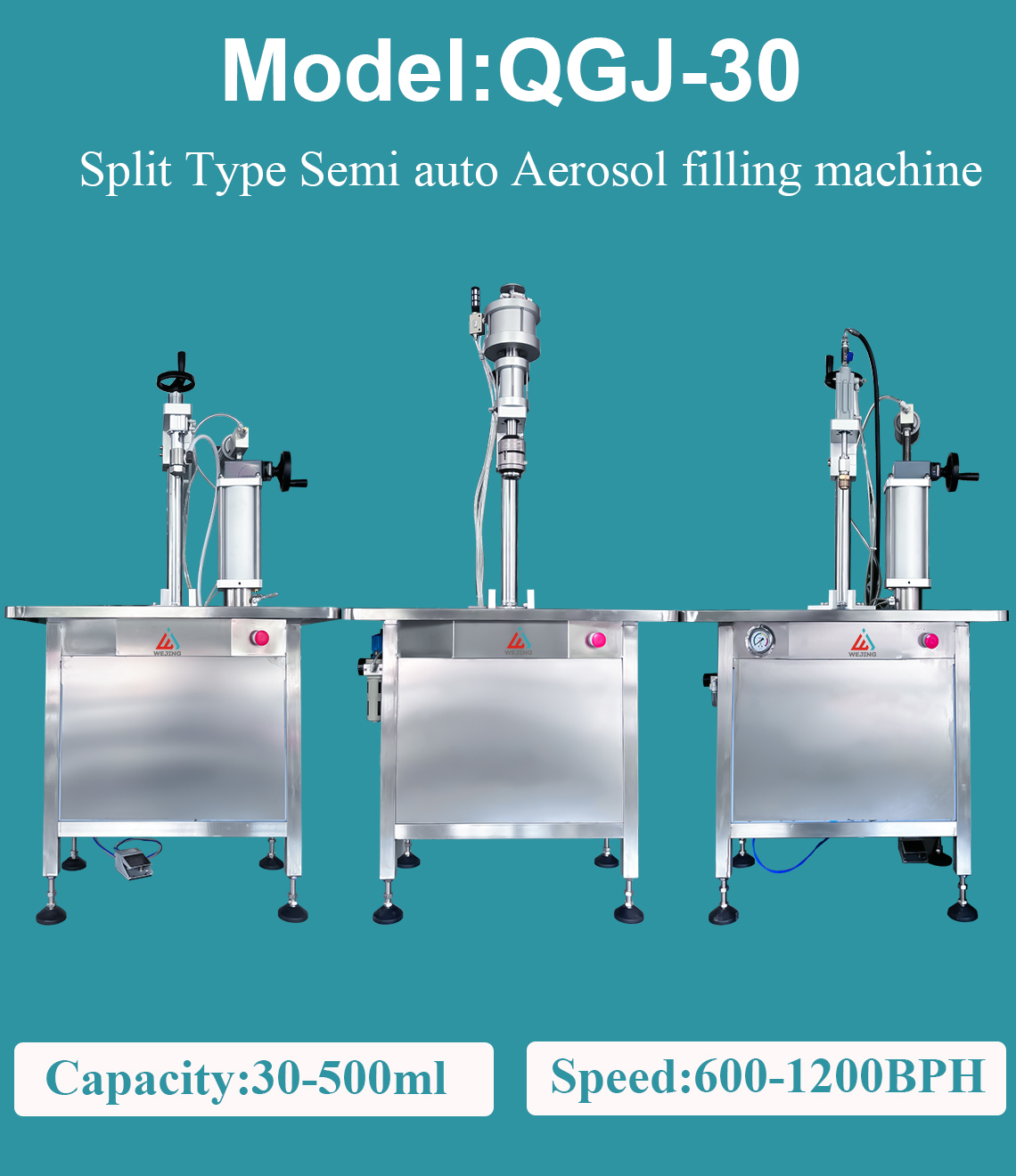

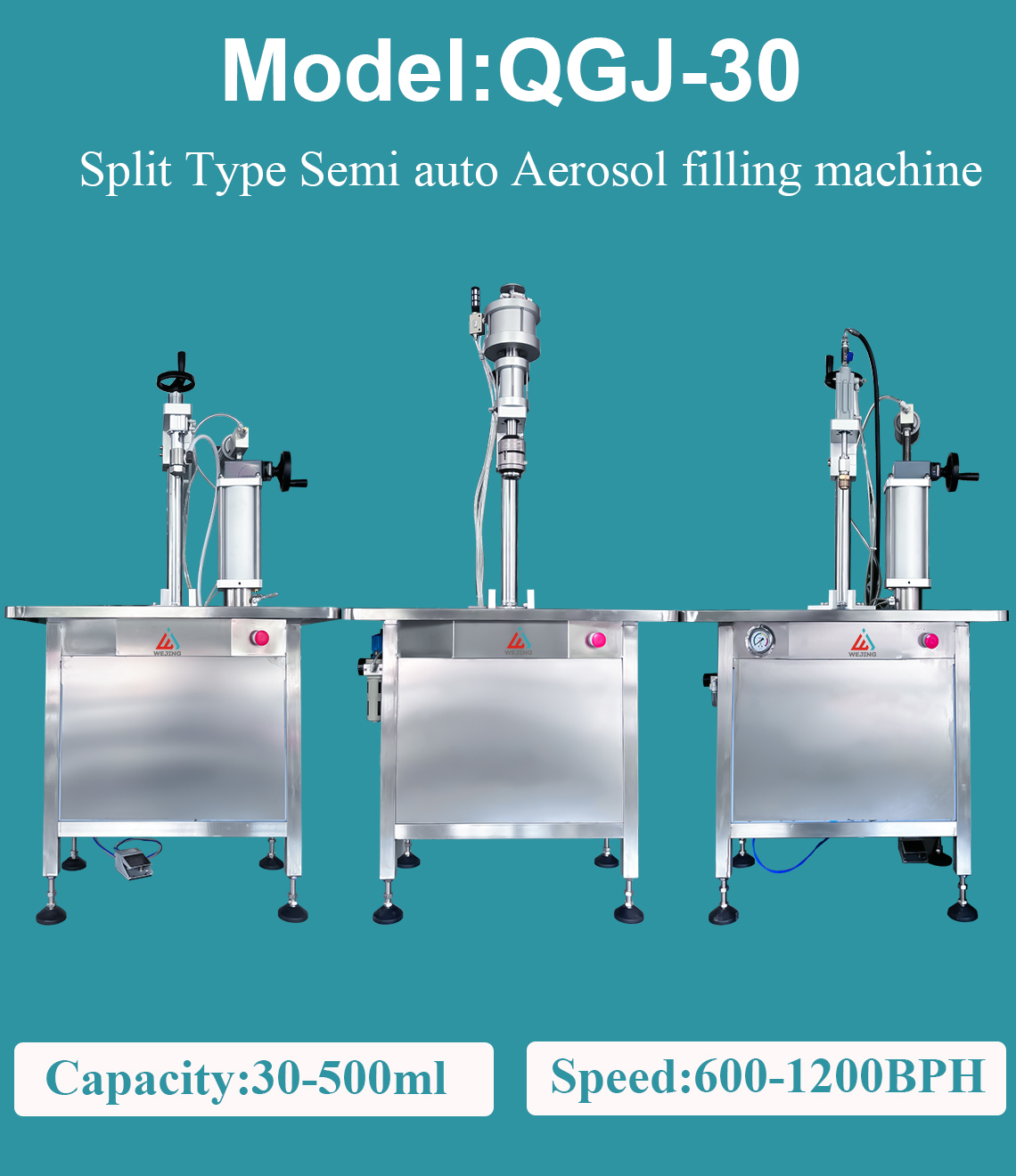

The QGJ-30 Semi-Automatic Aerosol Filling Machine consists of a liquid filling unit, sealing unit, and gas charging unit (including a booster pump).

Highly flexible, fast filling speed, high precision (≤±1%),  and easy adjustment for bottle changeovers. and easy adjustment for bottle changeovers. | The QGJS-20 Semi-Automatic 3-in-1 Aerosol Filling Machine integrates three functions—liquid filling, sealing, and gas charging—into a single workstation. A single operator can complete all actions simultaneously with one press of the foot valve.

This standard three-in-one integrated machine offers high integration, saving space and labor while ensuring simple operation. | The QGJV-20 Semi-Automatic 4-in-1 Aerosol Filling Machine integrates liquid filling, valve support, sealing, and gas charging into a single operation, completing all four processes simultaneously with one action.

The integrated valve support process further reduces labor requirements and streamlines the workflow. |

(2)  LineMedium-to-large production lines (stable mass production)

LineMedium-to-large production lines (stable mass production)

For enterprises with stable sales channels and large-scale production, we recommend the fully automated aerosol filling production line. This line comprises a turntable-type four-head liquid filling machine, turntable-type sealing unit, four-head gas charging machine, automatic valve applicator, automatic weighing system, automatic nozzle pressing unit, automatic capping press, coding machine, and conveyor belt. It can be integrated with a water bath leak detection system. All processes are mechanized, significantly reducing labor requirements and making it highly suitable for aerosol manufacturers with ultra-high-volume production needs.

Note: Customization available based on specific client requirements.

1 | Filling capacity | 60-70cans/min |

2 | Liquid filling volume | 30-1200 ml ( can be customized) |

3 | Gas filling volume | 30-1200ml( can be customized) |

4 | Filling heads | 4 liquid heads & 4 gas filling head |

5 | Filling accuracy | ≤±1% |

6 | Applicable cans diameter | 35 - 70mm( can be customized) |

7 | Applicable cans height (mm) | 80 - 300mm( can be customized) |

8 | Applicable valve | 1 inch |

9 | Working pressure | 0.6 - 0.8Mpa |

10 | Max gas consumption | 5m3/min |

11 | Material | SS304 ( some parts can be SS316) |

12 | Power | 7.5KW |

13 | Warranty | 2 years |