Product Advantage:

1. Compact design: Saves space in the production area.

2. Low maintenance cost: Requires minimal upkeep and spare parts.

3. Energy efficient: Consumes less power during operation.

4. Advanced safety features: Protects workers and equipment.

5. Quick setup: Ready for production in a short time.

Technical Parameters:

Capacity | 600-1200 cans/ hour, depending on filing volume |

Liquid filling capacity | 30-500ml(can be adjustable) |

Gas filling capacity | 30-500ml(can be adjustable) |

Filling accuracy | ≤±1% |

Applicable aerosol can diameter | 40-70mm |

Suitable aerosol can height | 70-300mm |

Air source | 0.5-0.6Mpa |

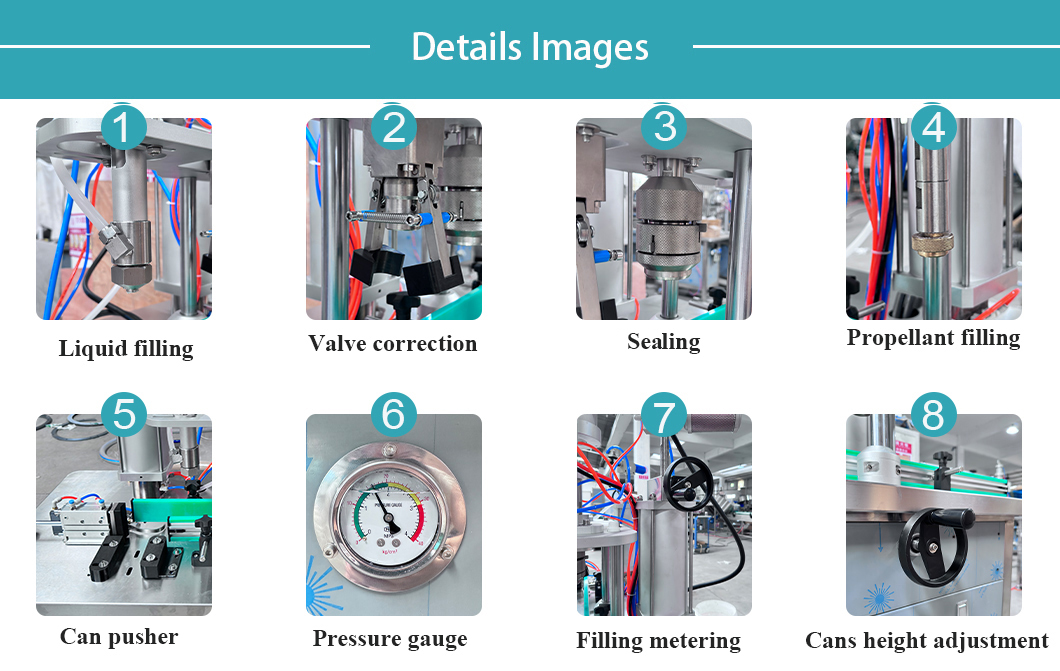

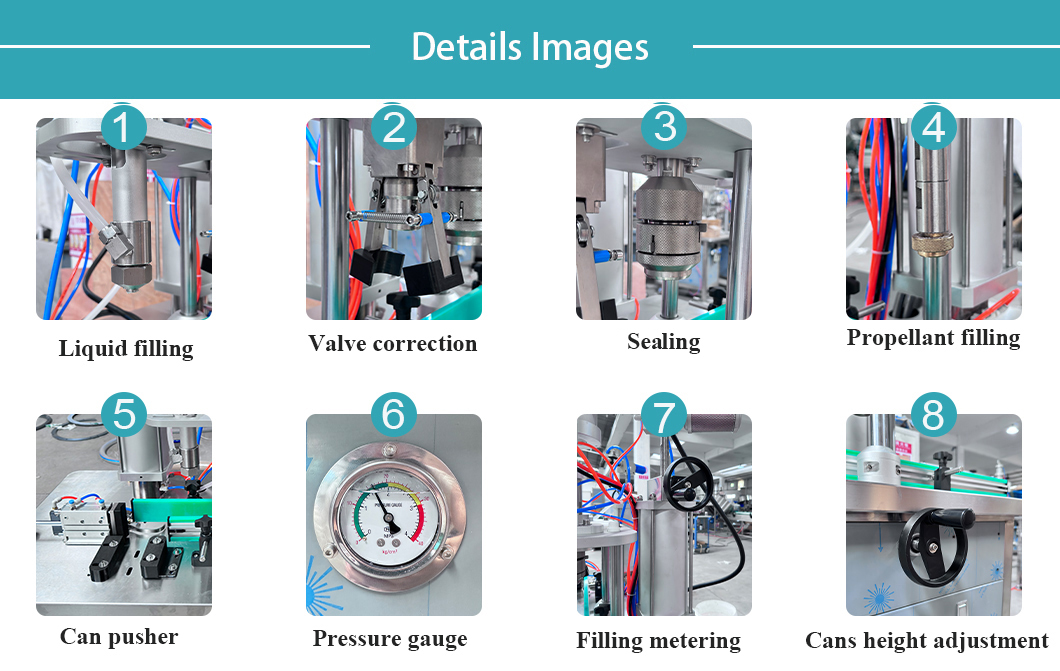

Detail Images:

1. QGJV20 aerosol filling machine 4 in 1, is with fourfunctions: liquid filling ,valve correcting, valve crimping ,propellant gas filling

2. The liquid filling system has the function of automatically inhaling liquid, which can fill high viscosity medium , and we can adjust the volume of filling.

3. The valve sealing system has a high precision sealing head, large capacity cylinder, even if low air pressure 0.5-0.6MPa, can also have a high quality sealing effect.

4. The propellant gas filling system mainly used for propellant such as (CO2 ,butane gas,nitrogen ,Freon, dimethyl ether and 134a, etc.) ,Corrosion resistance. Main seals are imported. Applicable to all kinds of aerosol filling valve.

5. Aerosol cans pushing forward automatically.

Product Uses:

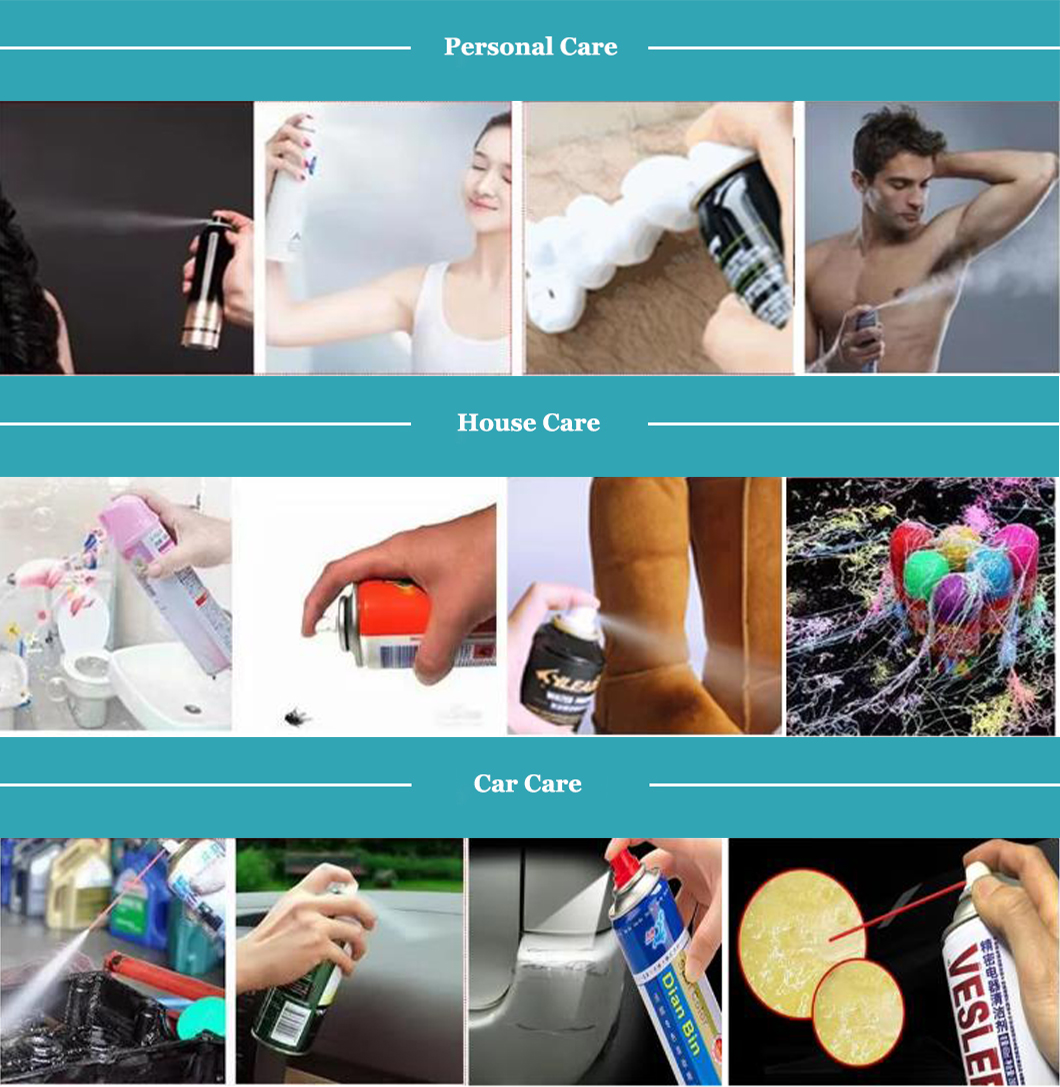

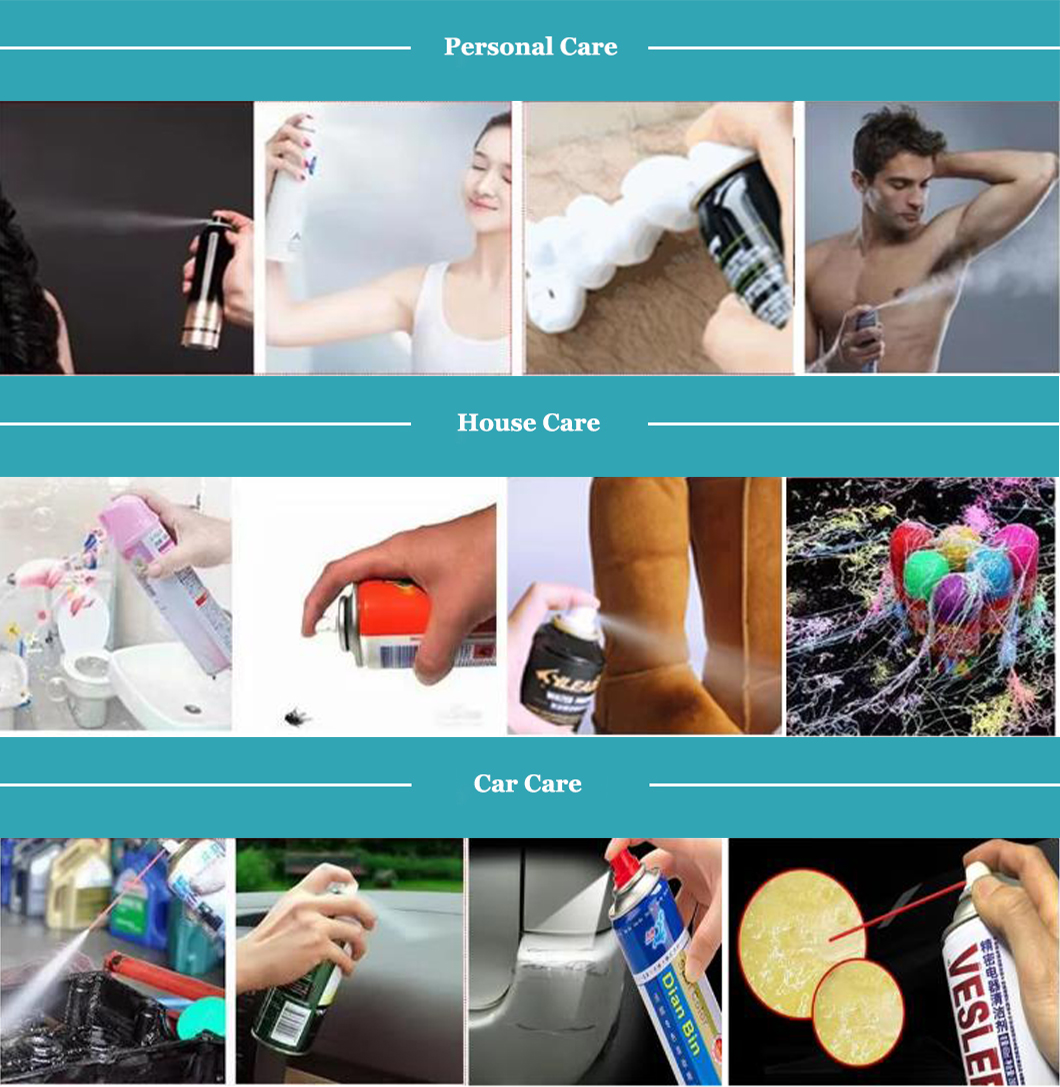

This filling machine can be widely used in the production of various aerosol products, such as pesticides, Air fresheners, Car care products, Hair spray, Air fresheners, Insecticides, Disinfectants,Fire extinguishing agents, Carburetor cleaner,Sunscreen Spray ,Nasal spray, Cosmetic Spray Evian ,Perfume Spray,shaving foam ,Spray paint....etc. Its high efficiency and versatility can help enterprises greatly improve production efficiency and reduce production costs, while also ensuring product quality and stability. In addition, the equipment also has the advantages of simple operation and easy maintenance, which is very suitable for small and medium-sized enterprises.

FAQ:

1. How often does the machine need maintenance?

It depends on usage, but a general rule is at least once a month for optimal performance.

2. Can it handle different sizes of aerosol cans?

Yes, it is adjustable to accommodate various can sizes within a certain range.

3. What if the machine malfunctions?

Contact our technical support immediately. We provide prompt troubleshooting assistance.

4. How accurate is the filling process?

The filling accuracy is typically within ±1%, ensuring consistent quality.

5. Does the machine come with a warranty?

Yes, it comes with a one-year warranty covering manufacturing defects.