|

Product Description

1)This area can be fully edited and gives you the opportunity tointroduce yourself, your website, your products or your services. This area can be fully edited and gives you the opportunity to introduce yourself, your website, your products or your services. This area can be fully edited and gives you the opportunity to introduce yourself, your website, your products or your services. This area can be fully edited and gives you the opportunity to introduce yourself, your website, your products or your services.This area can be fully edited and gives you the opportunity to introduce yourself, your website, your products or your services.

2)This area can be fully edited and gives you the opportunity to introduce yourself, your website, your products or your services.

|Technical parameters

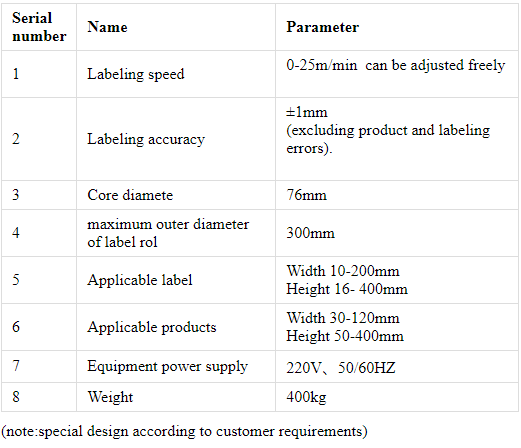

1. | Labeling speed | 0-25m/min( can be adjusted freely) |

2. | Labeling accuracy | ±1mm (excluding packaging and label errors). |

3. | Paper roll | Inner diameter 76mm Maximum paper roll outer diameter Dia.300mm. |

4. | Applicable label | Hength 10- 200mm |

5. | Width 16-400mm |

6. | Applicable bottle | Minimum size: 30mm(W)*50mm(H) |

7. | Largest size:120mm(W)* 400MM(H) |

8. | Power supply | 220V/50 Hz, 0.8KW |

9. | Air source | 0.4-0.8Kg |

10. | Mechanical dimensions | 3000x1450x1400mm(L*W*H) |

11. | Equipment weight | 400kg |

|Equipment characteristics

The machine body is made of 304 stainless steel, which meets the requirements of GMP.

The machine can be controlled by computer single or double side marking, can be used for single-head round bottle, flat bottle side paste.

PLC with large man-machine interface control, with label length automatic learning, can adapt to different labels.

Multi-group labeling parameter memory, can quickly change the product production.

The conveyor and the pressing mechanism use the same power source, and the speed can be adjusted independently to ensure the stability of the label.

The mechanical structure of the whole machine adopts reinforced rigid design, simple and stable.

|Application

It can be used for irregular products or regular products corresponding to two labels on the side at the same time or control for unilateral side labeling, such as: chemical, petroleum, engine oil, dish soap, shampoo, shower gel, beverage cans... and other two-sided labeling, you can arbitrarily adjust the double-sided labeling angle, which can adapt to different labeling side surfaces.

|Machine operation

size, position, and alignment settings.

Load the flat objects onto the conveyor system.

Load the label roll onto the machine.

Set desired labeling parameters using the control panel.

Initiate the labeling process.

The machine automatically applies labels onto the flat surfaces of the products.

Advanced sensors and alignment systems ensure accurate label placement.

For double-sided labeling, labels are applied simultaneously on both sides.

Monitor the process for quality control.

The machine operates continuously, integrating seamlessly into your production line.

Perform regular maintenance and cleaning.

Diagnostic features assist in troubleshooting if any issues arise.

|FAQ

Q1: Can the machine handle different label sizes and materials?

Yes, our machine is designed to accommodate various label sizes, shapes, and materials. It offers flexibility for customization based on your specific labeling requirements.

Q2: Can the machine be integrated into an existing production line?

Yes, It can be synchronized with other equipment, such as packaging machines, for a fully automated labeling process.

Q3:Is the machine easy to operate?

Yes, our Double Side Flat Labeling Machine features an intuitive control panel, allowing for easy setup of labeling parameters and monitoring of the labeling process. Minimal training is required for operators to adapt to the machine.

Q4: How fast can they label bottles?

Labeling speed varies, but they can label a large number of bottles per minute.

Q5: What maintenance is required for the machine?

Regular maintenance and cleaning are recommended to keep the machine in optimal condition. This ensures its reliable and consistent performance. The machine is equipped with diagnostic features to assist in troubleshooting if any issues arise.