2024.6.6 update

Equipment characteristics:

1. Labeling Versatility: Our cutting-edge labeling machine excels in handling a wide range of label types, including self-adhesive labels, wrap-around labels, and partial wrap labels. This versatility provides flexible labeling options to meet diverse product requirements.

2. Customizable Labeling Modes: Tailored to different bottle sizes and label positions, our labeling machine offers adjustable labeling modes. This ensures seamless integration with various packaging configurations, enhancing operational flexibility.

3. Precision Label Placement: Equipped with advanced sensors and precision mechanisms, our labeling machine guarantees precise label placement on each bottle. This meticulous attention to detail ensures a professional and uniform appearance for every product.

4. User-Friendly Operation and Control: Our labeling machine is designed for user convenience. With intuitive controls and easy setup, operators can swiftly configure the machine for different bottle types and label sizes. This streamlines the labeling process and minimizes downtime.

5. Unwavering Performance: Crafted with top-quality materials and components, our labeling machine delivers unwavering performance. Engineered for durability, it minimizes downtime and maximizes operational efficiency, ensuring a reliable and consistent labeling process.

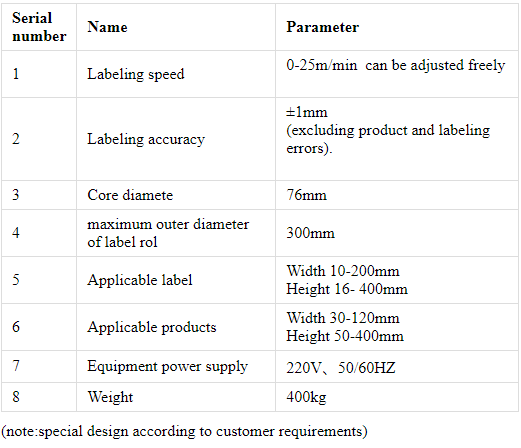

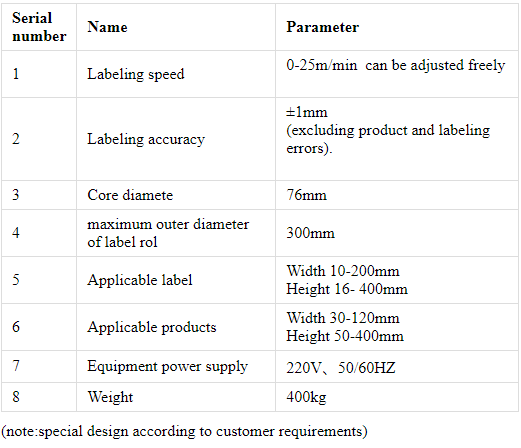

Technical Parameters:

Product application

The application of automatic labeling machines extends across a wide range of industries, including but not limited to food and beverage, pharmaceuticals, cosmetics, and household products. These machines are specifically designed to efficiently label round bottles made from various materials. This encompasses a diverse array of products such as sauces, beverages, medications, cosmetics, cleaning agents, and chemicals.

Product operation:

1. Set up the machine and fine-tune labeling parameters.

2. Place round bottles onto the machine's feeding system.

3. Mount the label roll onto the machine.

4. The machine accurately detects the position of each bottle.

5. The machine affixes the label onto the surface of the bottle.

6. Verify that the label adheres securely and appears smooth.

7. Conduct quality control checks to examine the labeled bottles.

8. The machine releases the labeled bottles upon completion.

9. Continuously monitor machine performance and perform necessary maintenance tasks.