Product Advantage:

1. High-speed Labeling

- Rapid sticker application

- Precise placement on aerosol cans

- Increases production output

2. Seamless Integration

- Fits into existing aerosol filling lines

- Reduces manual labor requirements

- Enhances overall production efficiency

3. Versatile Compatibility

- Adapts to various aerosol can sizes

- Accommodates different product specifications

- Enables production flexibility

4. User-friendly Interface

- Intuitive controls for easy operation

- Simple adjustments for different settings

- Minimizes operator training time

5. Durable Construction

- Built with robust materials

- Ensures long-term performance

- Reduces maintenance frequency and costs

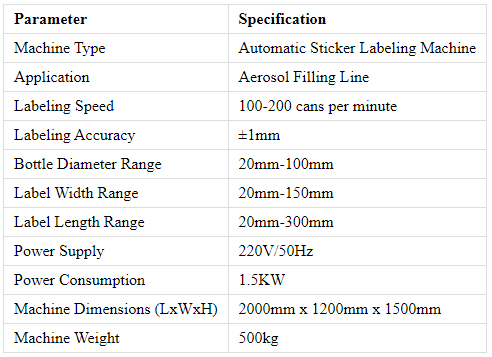

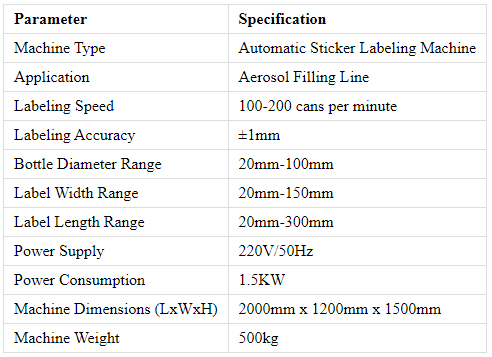

Technical Parameters:

Product Operate Guide:

1. Machine Setup

- Connect to power supply

- Integrate with aerosol filling line

- Verify all connections

2. Adjustment

- Set parameters for aerosol can size

- Configure label width and length

- Fine-tune settings for specific product requirements

3. Label Loading

- Insert labels into labeling system

- Align labels correctly

- Adjust tension for smooth feed

4. Operation

- Start labeling process

- Monitor label application

- Check label positioning on cans

5. Maintenance

- Conduct regular inspections

- Clean machine components

- Address operational issues promptly

Product Features:

1. Label Size Compatibility

- Accommodates various label widths and lengths

- Suitable for different aerosol can sizes

2. Product Versatility

- Labels diverse aerosol products

- Suitable for cosmetics, pharmaceuticals, and household items

3. Labeling Speed

- Processes 100-200 cans per minute

- Ensures efficient, high-speed production

4. Accuracy

- Offers labeling precision of ±1mm

- Ensures accurate label placement on aerosol cans

5. Maintenance Requirements

- Needs regular inspection and cleaning

- Requires periodic lubrication and component adjustment