Product Advantage

1. Enhanced Efficiency: Our inkjet conveyor belt accelerates the aerosol filling process, reducing production time and increasing output, improving overall operational efficiency.

2. Precise Inkjet Printing: The conveyor belt ensures consistent and accurate inkjet printing on aerosol bottles, enabling clear and legible labeling for improved product identification and traceability.

3. Portability and Flexibility: With its portable design, our conveyor belt can be easily moved and adjusted to fit different production setups, offering flexibility and adaptability in various environments.

4. Compact Size: The small and compact size of our conveyor belt allows it to be integrated seamlessly into existing production lines, optimizing space utilization and minimizing disruptions.

5. Reliable Performance: Built with high-quality materials and advanced technology, our inkjet conveyor belt delivers reliable and consistent performance, minimizing downtime and ensuring long-term productivity.

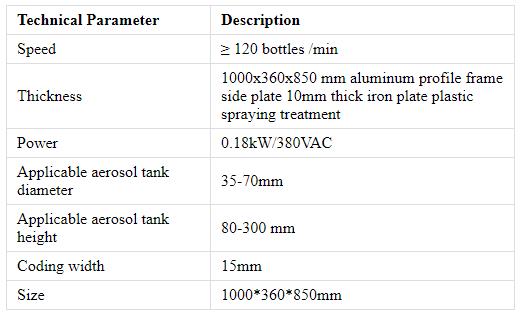

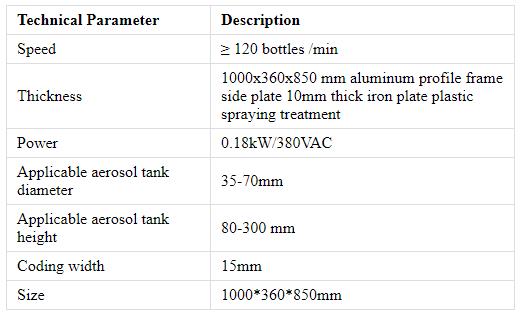

Technical Parameters

Product Uses

1. Labeling and Batch Tracking: The inkjet conveyor belt is specifically designed to facilitate precise inkjet printing for labeling and batch tracking on aerosol bottles.

2. Product Identification: It enables clear and legible printing of essential information such as product name, ingredients, usage instructions, and expiration dates on aerosol bottles.

3. Branding and Marketing: The conveyor belt allows for easy customization and branding, enabling companies to promote their brand and enhance product visibility through printed logos and graphics.

4. Compliance and Regulations: The inkjet conveyor belt helps meet regulatory requirements by providing a reliable and standardized method for printing necessary information mandated by regulatory bodies.

5. Quality Control: It assists in maintaining quality control by ensuring accurate and consistent printing, reducing the risk of errors or mislabeling, and enhancing overall product quality and customer satisfaction.

Product Operate Guide

1. Ensure the inkjet conveyor belt is securely installed and aligned with the aerosol filling machine, following the manufacturer's instructions and safety guidelines.

2. Adjust the conveyor belt speed to match the production line requirements, ensuring smooth and continuous movement of aerosol bottles for inkjet printing.

3. Set the desired printing parameters on the inkjet printer, such as font size, content, and position, to achieve accurate and legible printing on the aerosol bottles.

4. Place the aerosol bottles on the conveyor belt, ensuring they are properly spaced and aligned for consistent and efficient printing.

5. Monitor the inkjet printing process, regularly inspecting the quality and alignment of the printed information, and make necessary adjustments to optimize printing results.

FAQ

Q: Can the inkjet conveyor belt accommodate different sizes of aerosol bottles?

A: Yes, our conveyor belt is adjustable and can handle various sizes of aerosol bottles, providing flexibility for different product requirements.

Q: Is the inkjet printing on the aerosol bottles permanent and resistant to smudging?

A: Yes, our inkjet printing technology ensures durable and smudge-resistant prints on the aerosol bottles, maintaining the integrity of the labeling information.

Q: Can the conveyor belt be integrated with existing aerosol filling machines?

A: Yes, our inkjet conveyor belt is designed to be easily integrated with most aerosol filling machines, offering seamless compatibility and enhancing production efficiency.

Q: Does the conveyor belt require regular maintenance?

A: Yes, regular maintenance is recommended to ensure optimal performance. Our product comes with a maintenance guide that outlines the necessary steps for upkeep.

Q: Can the inkjet conveyor belt be used for other packaging applications besides aerosol bottles?

A: While our conveyor belt is primarily designed for aerosol bottles, it can be adapted for other packaging applications, such as labeling on cans or small containers, with proper adjustments.