Product Advantage:

1. Product Integrity: Aerosol filling machines maintain product integrity by preventing contamination and ensuring proper sealing, preserving the quality and shelf life of aerosol products.

2. Cost Efficiency: These machines optimize resource utilization, reducing material waste and minimizing production costs in the long run.

3. Consistency: Automatic aerosol filling machines deliver consistent and uniform fills, ensuring that each can contains the same amount of product, resulting in a standardized end product.

4. Speed: With their high-speed filling capabilities, aerosol filling machines significantly increase production rates, allowing manufacturers to meet tight deadlines and fulfill large orders efficiently.

5. Easy Integration: These machines can be seamlessly integrated into existing production lines, enhancing overall workflow and enabling manufacturers to scale their operations effectively.

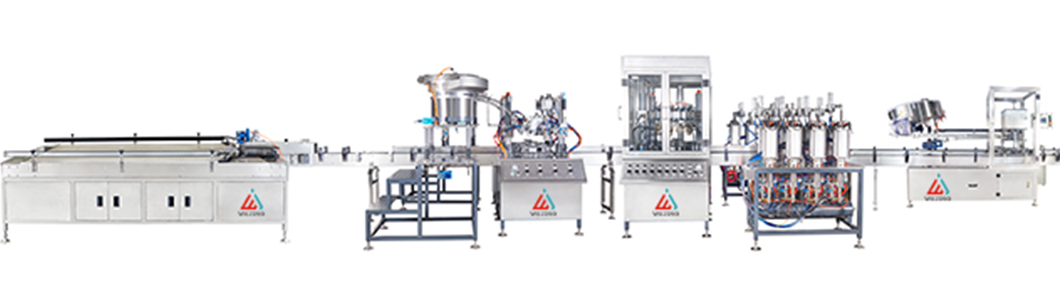

Technical Parameters:

Model Number | QGJ70 |

Place of Origin | Guangdong |

Certification | CE&ISO9001 |

Supply Ability | 10sets per month |

Production speed | 60-70 cans / min |

Capacity | 30-750ml ( Can Be Customized) |

Speed | High |

Gas consumption | 6.5m 3/ Min |

Dimension | 22000*3000*2000 mm |

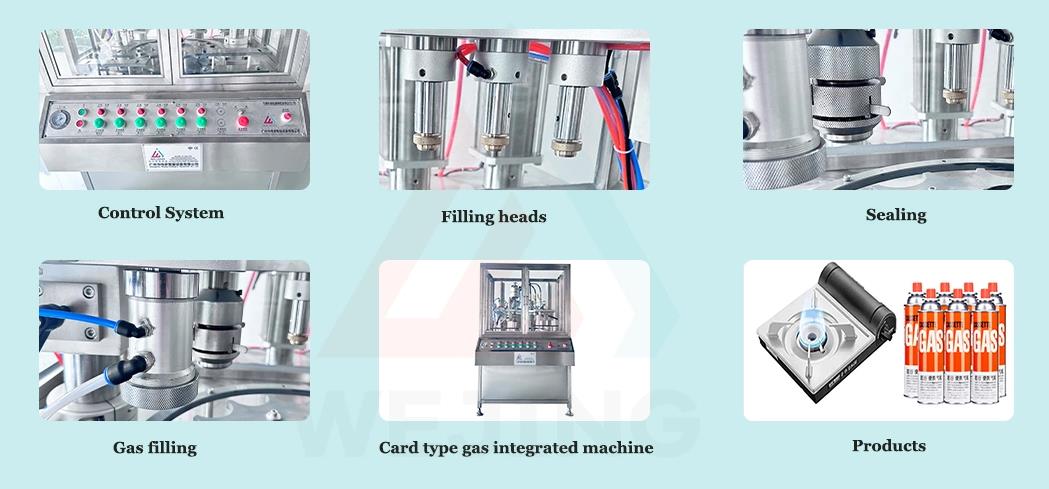

Detailed Images and Product Uses:

Cartridge gas: It could used for cooking when we have trip outside.

Product Operate Guide:

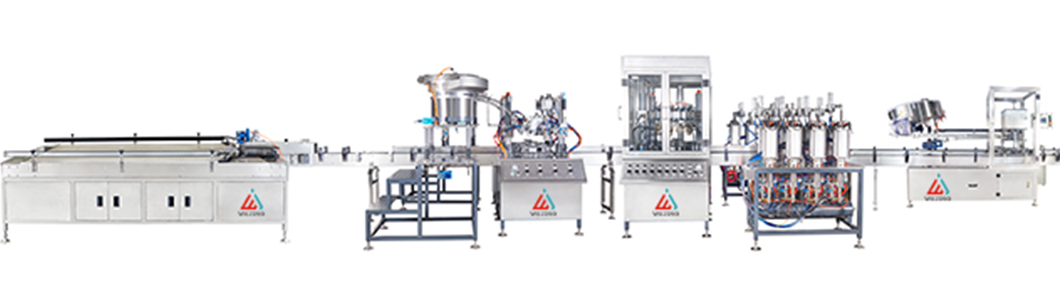

1. Machine Setup: Ensure all components are properly installed and calibrated before operation.

2. Product Preparation: Prepare the gas, ensuring they meet desired specifications.

3. Can Loading: Place empty cans onto the conveyor system, ensuring proper alignment and stability.

4. Filling Process: Start the machine and adjust settings for accurate filling, monitoring the process for any abnormalities.

5. Quality Control: Regularly inspect filled cans for proper volume, tight seals, and overall product quality.

FAQ:

1. Can this filling machines handle different propellant types?

Yes, aerosol filling machines can handle various propellant types, including compressed gases like nitrogen, carbon dioxide, and liquefied propellants like hydrocarbons.

2. Is it possible to integrate labeling capabilities into aerosol filling machines?

Some aerosol filling machines offer optional labeling modules that can be integrated into the production line for seamless filling and labeling operations.

3. What is the typical lifespan of an aerosol filling machine?

The lifespan of an aerosol filling machine can vary depending on factors like usage, maintenance, and build quality. Generally, a well-maintained machine can last for several years or even decades.

4. Are aerosol filling machines compatible with environmentally friendly propellants?

Yes, many modern aerosol filling machines are designed to accommodate environmentally friendly propellants like compressed air or nitrogen, helping to reduce the environmental impact of aerosol products.

5. Can aerosol filling machines handle custom can sizes and shapes?

Yes, some aerosol filling machines can be adjusted or customized to accommodate unique can sizes and shapes, meeting the specific requirements of different products and packaging designs.