Product Advantage:

1. Versatile Functionality: Our machine is designed to handle various packaging needs, accommodating different bottle sizes and shapes, providing flexibility for diverse product ranges.

2. Streamlined Operation: With its full automatic capabilities, the machine eliminates the need for manual intervention, reducing labor costs and ensuring consistent and efficient packaging.

3. Space-saving Design: The all-in-one design of our machine optimizes floor space, making it suitable for facilities with limited space availability.

4. High Speed and Accuracy: The machine operates at high speeds while maintaining precise and accurate packaging, maximizing productivity without compromising quality.

5. Easy Maintenance: Our machine is designed for easy maintenance, with accessible components and user-friendly interfaces, minimizing downtime and ensuring continuous operation.

Technical Parameters:

Parameter | Specification |

Machine Type | Robotic Case Packer |

Suitable for | Aerosol Gas Spray Filling Line |

Packaging Speed | Adjustable, up to 60 cases per minute |

Case Size Range | Length: 150-500mm; Width: 100-400mm; Height: 50-300mm |

Power Supply | 220V, 50Hz |

Air Pressure | 0.6-0.8 MPa |

Machine Dimensions | 3000x2000x1800mm(L*W*H) |

Weight | 900kg |

Product Uses:

1. Efficient Case Packing: Our machine automates the case packing process, ensuring efficient and consistent packaging of bottles, reducing manual labor and increasing productivity.

2. Seamless Integration: The all-in-one design allows for easy integration into existing production lines, streamlining workflow and optimizing overall efficiency.

3. Versatile Packaging: The machine is suitable for various industries, including food and beverage, pharmaceuticals, cosmetics, and more, accommodating different bottle types and sizes.

4. Product Protection: The machine provides secure and reliable packaging, protecting bottles during transportation and minimizing the risk of damage.

5. Cost-effective Solution: By automating the case packing process, our machine helps reduce labor costs and improve overall operational efficiency, providing a cost-effective packaging solution.

Product Operate Guide:

1. Set Bottle Parameters: Adjust the machine settings to match the dimensions and specifications of the bottles, including height, diameter, and packaging requirements.

2. Load Bottles: Place the bottles onto the machine's conveyor, ensuring proper alignment and spacing for seamless packaging.

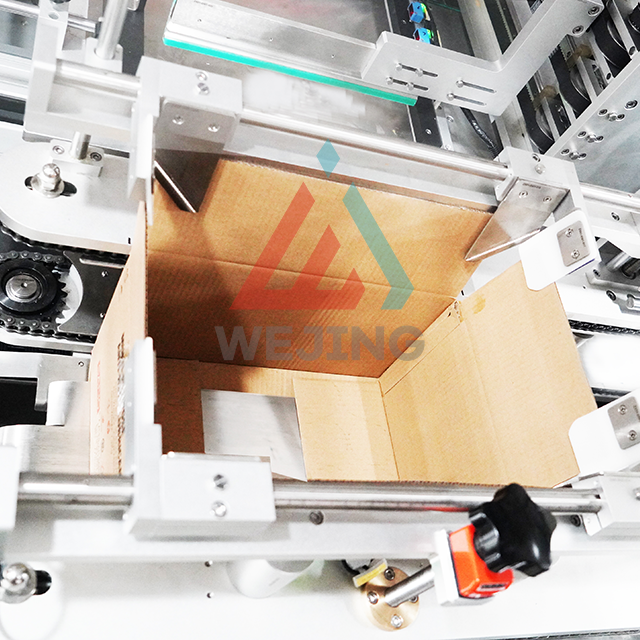

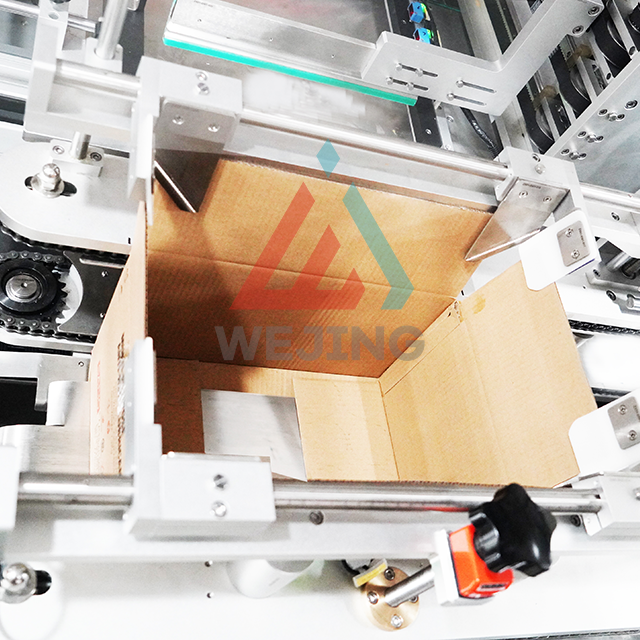

3. Set Case Parameters: Configure the machine to match the dimensions and requirements of the cases, including length, width, and stacking patterns.

4. Activate Machine: Start the machine and monitor its operation, ensuring smooth and accurate case packing of the bottles.

5. Maintenance and Troubleshooting: Regularly clean and inspect the machine, addressing any issues promptly to ensure optimal performance and minimize downtime.

FAQ:

1. Can the machine handle different bottle shapes and sizes?

Yes, our machine is designed to accommodate various bottle shapes and sizes, providing flexibility for different product packaging requirements.

2. Is the machine compatible with different case types?

Absolutely, our machine is versatile and can handle different case types, including cardboard, corrugated, and plastic cases.

3. How can I ensure the machine operates at the desired speed?

You can adjust the machine settings to set the desired packaging speed, allowing for optimal efficiency and meeting production demands.

4. Does the machine require regular maintenance?

Yes, regular maintenance is recommended to ensure the machine's optimal performance. We provide a maintenance guide and support for any troubleshooting needs.

5. Can the machine be integrated into existing production lines?

Yes, our machine is designed for seamless integration into existing production lines, facilitating a smooth workflow and maximizing overall efficiency.