Product Advantage

1. Versatile Application: Our management machine is designed to handle various aerosol products, including DMSO spray, thermo spray, aerosol gel, and aerosol mist, providing flexibility for different production needs.

2. Enhanced Efficiency: With its fully automatic functionality, this machine optimizes the production process, reducing labor costs and increasing overall productivity.

3. Precise Filling and Sealing: The machine ensures accurate filling and sealing of aerosol bottles, minimizing product waste and ensuring consistent product quality.

4. Reliable Labeling: Our management machine incorporates reliable labeling technology, ensuring accurate and consistent labeling of aerosol bottles, enhancing brand image and compliance with regulatory requirements.

5. Streamlined Management: This machine offers streamlined management of aerosol bottle production, with features such as batch tracking, data recording, and remote monitoring, facilitating efficient production planning and quality control.

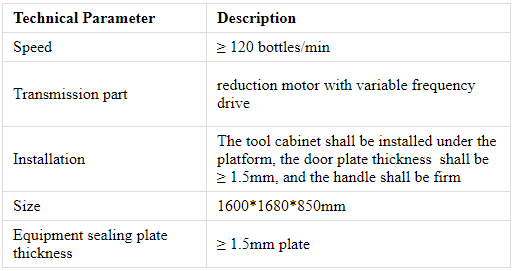

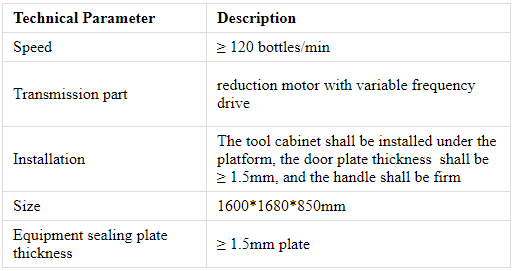

Technical Parameters

Product Uses

1. Personal Care Industry: Our management machine is ideal for the production of aerosol products in the personal care industry, such as hair sprays, deodorants, and body mists, ensuring efficient and precise filling and packaging.

2. Household Products: This machine is suitable for the production of aerosol products used in household cleaning, air freshening, and insect repellent applications, ensuring consistent quality and productivity.

3. Automotive Industry: Our management machine is utilized for the production of aerosol products used in automotive care, such as tire shine, lubricants, and rust inhibitors, ensuring accurate filling and labeling for optimal performance.

4. Industrial Applications: This machine is employed for the production of aerosol products used in various industrial applications, such as paints, coatings, and adhesives, ensuring precise formulations and efficient packaging.

5. Pharmaceuticals: Our management machine is utilized for the production of aerosol products in the pharmaceutical industry, including nasal sprays and inhalers, ensuring accurate dosing and compliance with regulatory standards.

Product Operate Guide

1. Ensure the machine is properly installed and connected to power and air supply before operation, following the manufacturer's instructions.

2. Set the desired parameters on the control panel, including filling volume, sealing pressure, labeling specifications, and production speed.

3. Place empty aerosol bottles on the conveyor belt, ensuring they are properly aligned and spaced for efficient processing.

4. Start the machine and monitor the production process, ensuring that each bottle is filled, sealed, and labeled accurately and within the specified parameters.

5. Regularly inspect and maintain the machine, including cleaning the nozzles, replacing worn-out parts, and calibrating as necessary, to ensure optimal performance and product quality.

FAQ

Q: Can this machine handle different sizes of aerosol bottles?

A: Yes, our management machine is designed to accommodate various sizes of aerosol bottles, providing flexibility for different product requirements.

Q: Does the machine require specialized training to operate?

A: While basic training is recommended, our management machine is user-friendly and comes with a detailed operating manual to guide operators through the process.

Q: How does the machine ensure accurate filling and sealing of aerosol bottles?

A: Our machine is equipped with precise sensors and control systems that monitor and adjust the filling and sealing process to ensure accurate and consistent results.

Q: Can the machine handle different types of aerosol products, such as liquids and gels?

A: Yes, our management machine is versatile and can handle various types of aerosol products, including liquids, gels, sprays, and mists.

Q: What kind of after-sales support is provided?

A: We offer comprehensive after-sales support, including technical assistance, spare parts availability, and maintenance services, to ensure smooth operation and customer satisfaction.