Product Advantage:

1. Advanced technology allows for simultaneous filling of two aerosol cans, doubling production output.

2. Precise filling control ensures consistent and accurate fill levels, reducing product waste and improving quality.

3. Versatile design accommodates a wide range of aerosol can sizes and upper valve designs.

4. Easy integration into existing aerosol filling lines, minimizing downtime and increasing overall efficiency.

5. Robust construction and reliable performance ensure long-term durability and minimal maintenance requirements.

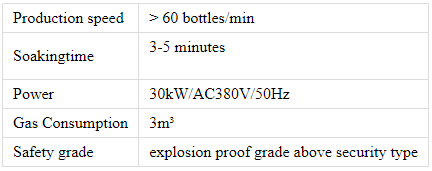

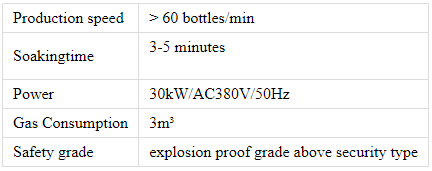

Technical Parameters:

Product Uses:

1. Suitable for filling aerosol products with upper valve designs, including air fresheners, deodorants, and insecticides.

2. Ideal for industries requiring high-speed aerosol production, such as personal care, household, and automotive.

3. Enables efficient and precise filling, ensuring accurate product quantities and reducing wastage.

4. Compatible with a wide range of aerosol can sizes, providing versatility for different packaging requirements.

5. Enhances production efficiency by allowing simultaneous filling of two units, reducing production time and costs.

Product Operate Guide:

1. Ensure the machine is properly connected to power and air supply, and all safety measures are in place.

2. Adjust the settings on the control panel for desired filling parameters, such as fill volume and speed.

3. Load aerosol cans into the designated feeding system, ensuring proper alignment and stability.

4. Start the machine and monitor the filling process, ensuring smooth operation and consistent product quality.

5. Regularly inspect and clean the machine to maintain optimal performance and prevent any potential issues.

FAQ:

Q: Can the machine handle different types of upper valve designs?

A: Yes, the machine is designed to accommodate various upper valve designs for different aerosol products.

Q: What is the maximum filling capacity of the machine?

A: The machine can fill aerosol products with a maximum capacity of [insert capacity] per unit.

Q: Is the machine compatible with different aerosol can sizes?

A: Yes, the machine is adjustable and can accommodate a range of aerosol can sizes for versatile production.

Q: How do I troubleshoot any issues during operation?

A: The machine is equipped with a user-friendly interface and troubleshooting guide to assist in resolving common issues.

Q: What maintenance is required for the machine?

A: Regular cleaning, lubrication, and inspection of the machine's components are recommended to ensure optimal performance and longevity.