Updated on April 15, 2024

Product Advantages :

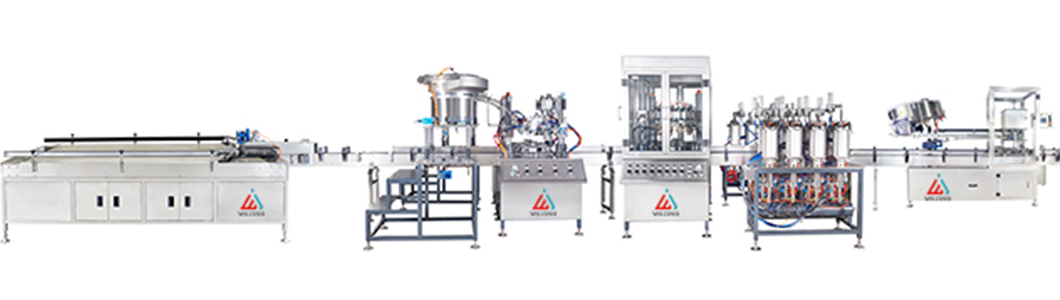

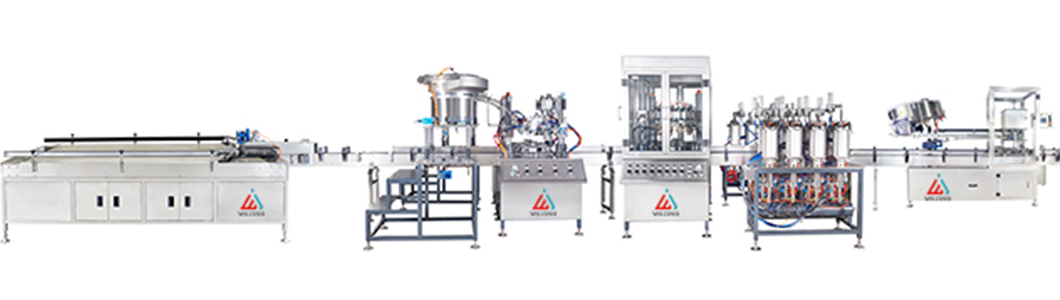

The automatic filling production line of high-speed aerosol is a combination of sophisticated machinery. It is made up of:

A double rotary table 12 head Liquid filling machine

A valve inserting machine

A 10 head Gas filling machine

A water bath machine

A weighing machine

An actuator placing machine

An outer cap pressing machine

Booster pump

Conveyor belt

This assembly of equipment from the automatic filling production line of high-speed aerosol works together to provide a reliable and efficient way to produce aerosols. It ensures that products are of consistently high-level quality.

Applications:

The production line is of high precision and high efficiency, thus meeting international 1 inch filling specifications. It is applicable to tinplate, aluminum cans, and is suitable to be filled with medium oil, water-base material, emulsion solvent and similar mediump viscosity materials. Furthermore, propellants such as DME, LPG, 134a, N2 and CO2 are all suitable for being filled by this production line. In conclusion, this production line can be widely used in chemical, daily chemical, food and pharmaceutical industries for aerosol spray.

Customization:

Model Number | QGJ70 |

Place of Origin | Guangdong |

Certification | CE&ISO9001 |

Supply Ability | 10sets per month |

Production speed | 60-70 cans / min |

Capacity | 30-750ml ( Can Be Customized) |

Speed | High |

Gas consumption | 6.5m 3/ Min |

Dimension | 22000*3000*2000 mm |

Technical Parameters:

The production speed of this machine is between 100 to 120 bottles per minute. The filling volume ranges from 30 to 750ml, and this machine can even achieve a repeat filling accuracy of ± 1%. It can also suitable for 1inch valve, and suitable for can diameter from 35 to 73.85mm,width up to 310mm. In addition, this machine requires a compressed air pressure of 0.7 to 0.85mpa and a gas consumption rate of 5m3/min. Lastly, the power supply for this machine is AC380V 50HZ, it also could be customized to 220V60HZ or 450V 60HZ.

Packing and Shipping:

The Automated Filling Machine is packaged securely in a poly-wood box and shipped to the customer's location. The box is then secured with tape and labeled with an address sticker.