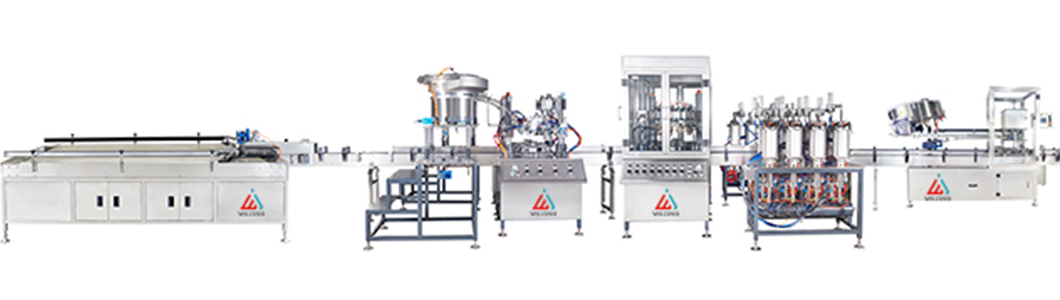

Product Advantage:

1. Increased Productivity: Aerosol filling machines streamline production, allowing for faster filling rates and higher output.

2. Consistent Fill Levels: These machines ensure precise dosing, maintaining product consistency and quality.

3. Minimal Operator Intervention: Automatic operation reduces labor requirements and frees up personnel for other tasks.

4. Improved Efficiency: Aerosol filling machines optimize resource utilization, minimizing waste and reducing production costs.

5. Enhanced Safety: These machines incorporate safety features to protect operators and minimize the risk of accidents during the filling process.

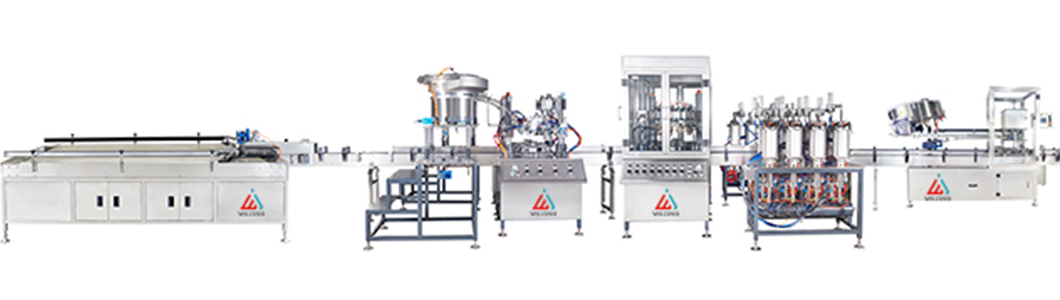

Technical Parameters:

Parameter | Value |

Filling capacity (cans/min) | 60-70 cans/min |

Gas filling volume (ml) | 10 - 300 each head |

Filling accuracy | ≤±1% |

Applicable cans diameter (mm) | 35 - 65( can be customized) |

Applicable cans height (mm) | 80 - 350( can be customized) |

Applicable valve (mm) | 1 inch |

Working pressure (Mpa) | 0.6 - 0.8 |

Max gas consumption (m3/min) | 2.5 |

Power (KW) | 4.5 |

Dimension (LWH) mm | 1500*1100*1200 |

Material | SS304(some parts can be SS316) |

Warranty | 1 year |

Key Selling Points | High speed fully automatic high production |

Maintenance Requirements | Recommended maintenance procedures and schedules |

Certifications and Standards | CE&ISO9001 |

Product Uses:

This machine also could add some parts to achieve following function:

1. Beauty and Cosmetics: Aerosol filling machines are used for filling cosmetic products such as sunscreens, self-tanning sprays, makeup setting sprays, and hair styling products.

2. Automotive Care: These machines are employed for filling car care products like tire inflators, engine degreasers, interior cleaners, and brake cleaners.

3. Paints and Coatings: Aerosol filling machines are utilized for filling spray paints, touch-up paints, clear coatings, and specialty coatings used in various industries.

4. Industrial Maintenance: They are used for filling lubricants, penetrating oils, corrosion inhibitors, and other maintenance products for industrial machinery and equipment.

5. Personal Protection: Aerosol filling machines are employed for filling personal protective equipment (PPE) sprays such as sunscreen sprays, insect repellents, and antibacterial sprays.

Product Operate Guide:

1. Operator Training: Ensure operators receive proper training on the machine's operation, safety protocols, and troubleshooting techniques.

2. Material Handling: Handle liquid and gas formulations with care, following appropriate safety measures and ensuring correct labeling and storage.

3. Machine Calibration: Regularly calibrate the machine to maintain accurate filling volumes and ensure consistent product quality.

4. Production Monitoring: Continuously monitor the production line, checking for any abnormalities, such as leaks, jams, or deviations from the desired filling parameters.

5. Documentation and Reporting: Maintain detailed records of production runs, including batch numbers, filling settings, and any issues encountered for quality control and traceability purposes.

FAQ:

1. How accurate is the filling process of aerosol filling machines?

Aerosol filling machines are designed to provide precise and accurate filling. The filling accuracy depends on various factors such as the machine's technology, calibration, and the chosen filling parameters. It's important to select a machine with a reputation for high accuracy and consider regular calibration for optimal results.

2. Can aerosol filling machines handle different product viscosities?

Yes, aerosol filling machines are versatile and can handle a wide range of product viscosities. They can be equipped with different filling mechanisms or nozzles to accommodate various viscosities, from thin liquids to thicker gels or creams.

3. Are aerosol filling machines suitable for small-scale production?

Yes, aerosol filling machines are available in different sizes and capacities, making them suitable for both small-scale and large-scale production. It's important to select a machine that matches the production requirements to achieve efficient and cost-effective filling processes.

4. What safety measures should be taken when operating an aerosol filling machine?

Safety is crucial when operating aerosol filling machines. Operators should follow safety guidelines provided by the manufacturer, including wearing appropriate protective equipment, handling flammable or hazardous materials with caution, and ensuring proper ventilation in the filling area.

5. How can maintenance and troubleshooting be performed on an aerosol filling machine?

Regular maintenance is essential to keep an aerosol filling machine in optimal condition. The manufacturer's guidelines should be followed for routine maintenance tasks such as cleaning, lubrication, and inspection. In case of issues or breakdowns, it's recommended to consult the machine's manual or contact the manufacturer for troubleshooting guidance or professional assistance.