2024.6.5 update

Product Advantage

1. High Efficiency: Our machine automates the filling process, increasing productivity and reducing labor costs.

2. Precise Filling: With advanced technology, it ensures accurate and consistent filling, minimizing product waste.

3. Versatile Compatibility: This machine is compatible with various aerosol spray cans, including PU foam aerosol cans.

4. Easy Operation: User-friendly controls and intuitive interface make it easy to operate and require minimal training.

5. Reliable Performance: Built with quality components, our machine offers reliable and stable operation, ensuring continuous production.

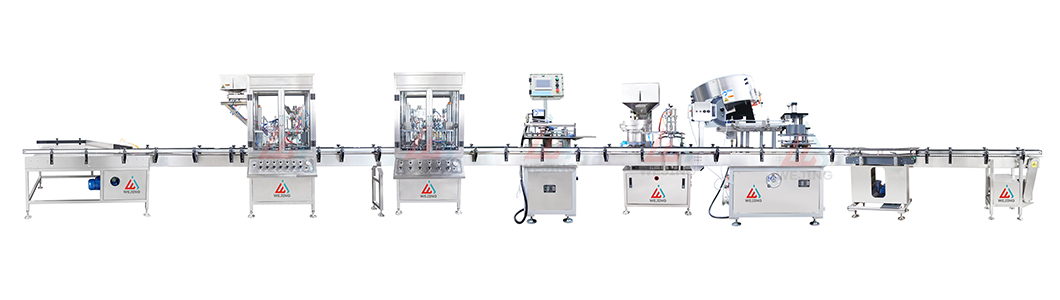

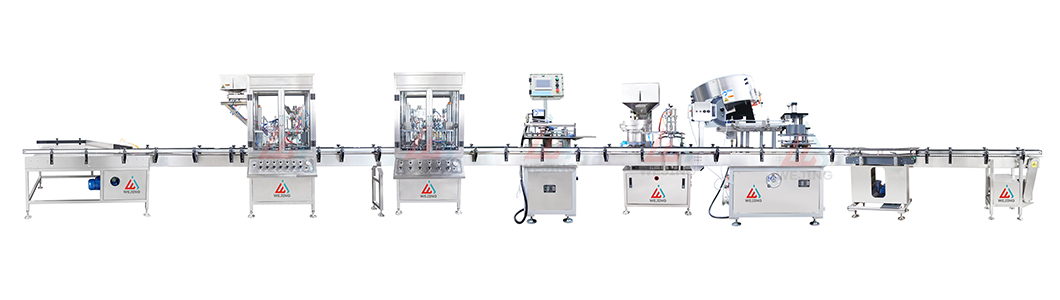

Technical Parameters

Technical Parameter | Description |

Filling capacity (cans/min) | 60-70 |

Liquid filling volume (ml) | 10-1200( can be customized) |

Gas filling volume (ml) | 10-1200( can be customized) |

Filling heads | 4 heads |

Filling accuracy | ≤±1% |

Applicable cans diameter (mm) | 35 - 70( can be customized) |

Applicable cans height (mm) | 80 - 300( can be customized) |

Applicable valve | 1 inch |

Working pressure (Mpa) | 0.6 - 0.8 |

Max gas consumption (m3/min) | 5 |

Power (KW) | 7.5 |

Dimension (LWH) mm | 22000*3500*2000 |

Material | SS304 ( some parts can be SS316) |

Warranty | 1 year |

Key Selling Points | High speed fully automatic high production |

Maintenance Requirements | Recommended maintenance procedures and schedules |

Certifications and Standards | CE&ISO9001 |

Detailed Images:

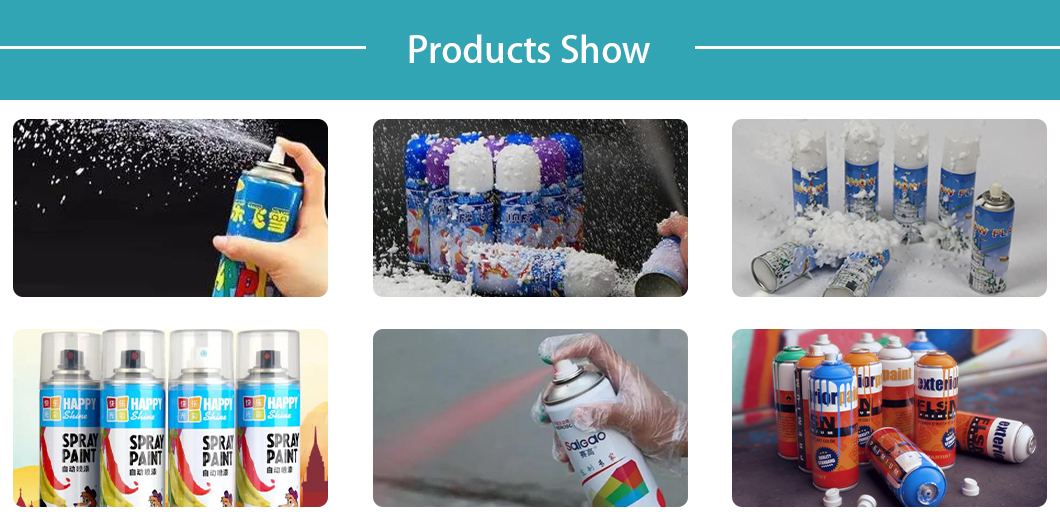

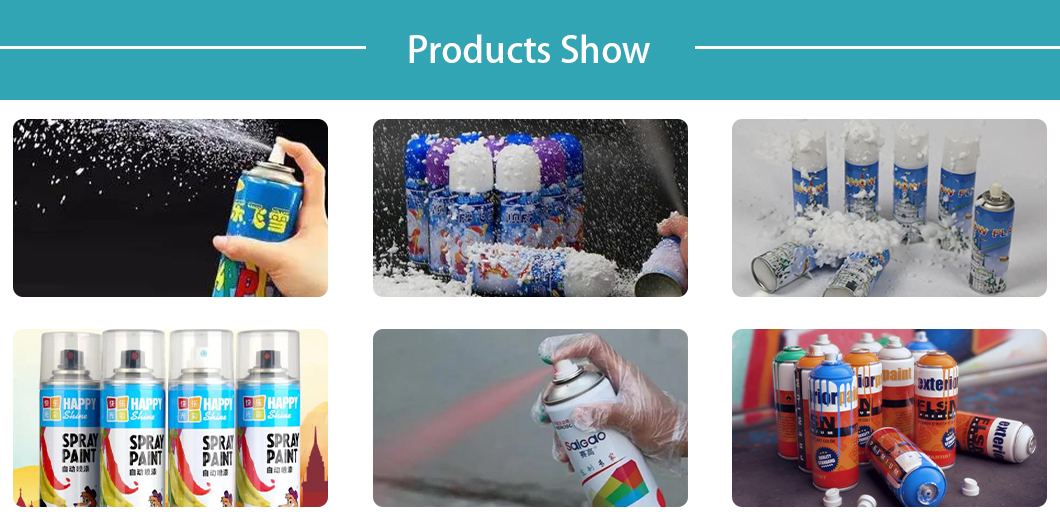

Product Uses

1. Cosmetic Industry: This machine is ideal for filling aerosol spray cans with cosmetics such as hairspray, deodorant, and body mist.

2. Household Products: It can be used to fill aerosol cans with household products like air fresheners, insecticides, and cleaning sprays.

3. Automotive and Industrial: This machine is suitable for filling aerosol cans with automotive and industrial products such as lubricants, paints, and adhesives.

4. Personal Care: It can be used to fill aerosol cans with personal care products like sunscreen, shaving foam, and dry shampoo.

5. Pharmaceuticals: This machine is suitable for filling aerosol cans with pharmaceutical products such as inhalers and nasal sprays.

Product Operate Guide

1. Preparation: Ensure all necessary materials, including aerosol cans and product formulation, are ready and properly aligned for efficient operation.

2. Machine Setup: Adjust the machine settings, including fill volume, valve placement, and propellant pressure, according to the specific requirements of your aerosol product.

3. Loading: Carefully load the empty aerosol cans onto the conveyor belt, ensuring proper alignment and avoiding any obstructions.

4. Start and Monitor: Start the machine and closely monitor the filling process, checking for any leaks or malfunctions, and adjusting settings if necessary.

5. Safety Measures: Adhere to safety protocols, including wearing protective gear, maintaining a clean workspace, and following proper disposal procedures for any waste materials.

FAQ

Q: Can this machine handle different sizes of aerosol cans?

A: Yes, our machine is adjustable and can accommodate various sizes of aerosol cans.

Q: Is it compatible with different types of propellants?

A: Absolutely, our machine is designed to work with a wide range of propellants commonly used in aerosol products.

Q: How often does the machine require maintenance?

A: Regular maintenance is recommended to keep the machine in optimal condition. The frequency of maintenance depends on the production volume and usage, typically ranging from monthly to quarterly.

Q: Is training required to operate the machine?

A: Basic training is recommended to ensure proper operation and maximize the machine's efficiency. We provide user manuals and offer training sessions upon request.

Q: What kind of technical support do you provide?

A: We offer comprehensive technical support, including remote assistance, troubleshooting guides, and spare parts availability, ensuring prompt and efficient resolution to any issues that may arise.