Product Advantage:

1. Unmatched Speed: This high-speed capper can cap aerosol bottles at an exceptional rate, significantly increasing production efficiency.

2. Precise and Secure Capping: The machine ensures precise and secure capping, preventing leakage and maintaining product integrity.

3. Easy Integration: Seamlessly integrates into existing aerosol filling lines, minimizing downtime and maximizing productivity.

4. User-Friendly Operation: The machine features a user-friendly interface, making it easy to operate and reducing the need for extensive training.

5. Reliable Performance: Built with advanced technology and high-quality components, the capping machine delivers consistent and reliable performance, ensuring long-term satisfaction.

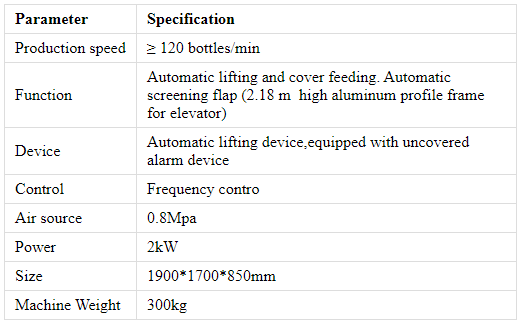

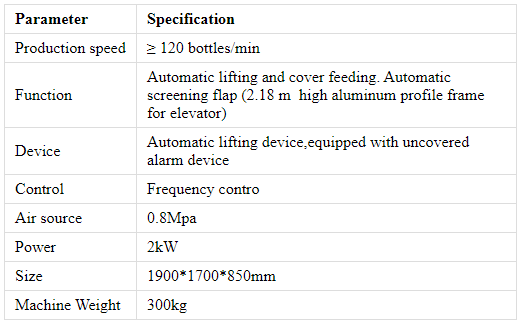

Technical Parameters:

Product Uses:

1. Ideal for aerosol manufacturing facilities, ensuring efficient capping of aerosol bottles in high-volume production lines.

2. Suitable for industries such as cosmetics, pharmaceuticals, and household products that require fast and accurate capping of aerosol containers.

3. Enables seamless integration into existing aerosol filling lines, enhancing overall production efficiency.

4. Ensures secure and tight caps, preventing leakage and maintaining product quality during storage and transportation.

5. Offers a reliable solution for automating the capping process, reducing manual labor and increasing productivity.

Product Operate Guide:

1. Ensure the machine is properly connected to the power supply and the aerosol filling line.

2. Adjust the machine settings according to the bottle size, cap type, and desired capping speed.

3. Load the bottles onto the conveyor system, ensuring proper alignment and spacing.

4. Start the machine and monitor the capping process, ensuring caps are securely and accurately applied to the bottles.

5. Regularly inspect and maintain the machine, including cleaning and lubricating components, to ensure optimal performance and longevity.

FAQ:

1. Can this machine handle different cap sizes and types?

Yes, the machine is designed to accommodate a wide range of cap sizes and types, providing flexibility for various aerosol bottle requirements.

2. What is the maximum capping speed of this machine?

The machine can cap bottles at a maximum speed of [insert specific speed], ensuring rapid and efficient production.

3. Is the capping process adjustable for different bottle heights?

Yes, the machine allows for easy adjustment of the capping process to accommodate different bottle heights, ensuring accurate and secure caps.

4. Does the machine have safety features to prevent accidents during operation?

Yes, the machine is equipped with safety features such as emergency stop buttons and protective guards to ensure operator safety.

5. What kind of maintenance is required for this machine?

Regular maintenance, including cleaning, lubrication, and inspection of components, is recommended to ensure optimal performance and prolong the machine's lifespan.