Product Advantage

Efficient Operation: Automates nozzle pressing, reducing manual work and boosting productivity in aerosol filling.

Precise and Consistent Sealing: Ensures accurate, reliable nozzle pressing for secure seals on every can.

Enhanced Safety: Built-in safety features protect workers and handle flammable aerosols safely.

Versatile Compatibility: Supports a wide range of aerosol products, meeting diverse production needs.

Cost-effective Solution: Lowers labor costs and reduces errors, delivering a budget-friendly option for manufacturers.

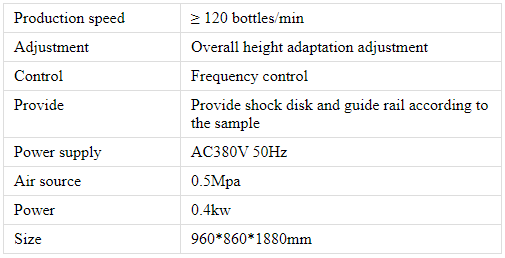

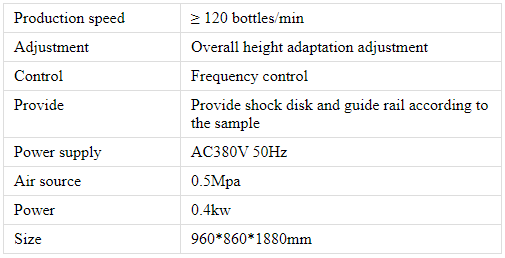

Technical Parameters

Product Uses

Beauty and Personal Care Products: Ideal for pressing nozzles on aerosol-based products like hairsprays, deodorants, and body sprays.

Household Cleaners: Used for pressing nozzles on cleaners like air fresheners and disinfectants.

Automotive and Industrial Products: Suitable for pressing nozzles on aerosol lubricants, degreasers, and rust inhibitors.

Insecticides and Pesticides: Ensures safe, effective nozzle pressing for pest control aerosols.

Paints and Coatings: Guarantees airtight nozzle pressing for aerosol paints and coatings.

Product Operate Guide

Prepare the Machine: Set up and calibrate the machine, adjusting nozzle pressing pressure and speed for the aerosol product.

Load Aerosol Cans: Place empty cans on the conveyor, ensuring correct alignment and spacing.

Start the Machine: Activate the machine, align nozzles with cans, and press nozzles automatically with pre-set pressure.

Monitor the Process: Watch for misaligned nozzles or pressing issues, and adjust to maintain proper sealing.

Quality Control: Inspect sealed cans regularly for leaks or improper seals, and adjust pressing parameters as needed.

FAQ

Q: Can the machine handle different sizes and shapes of aerosol cans?

A: Yes, the machine is designed to accommodate various sizes and shapes of aerosol cans, providing flexibility for different product requirements.

Q: Is the machine compatible with different types of aerosol products, such as flammable or corrosive ones?

A: Yes, the machine is designed to handle a wide range of aerosol products, including flammable, corrosive, and non-flammable ones, ensuring safe and efficient nozzle pressing.

Q: How easy is it to change the settings for different aerosol products?

A: The machine features a user-friendly interface, allowing operators to easily adjust the settings for different aerosol products, including nozzle pressing pressure and speed.

Q: Can the machine detect and reject cans with faulty or incomplete nozzle pressing?

A: Yes, the machine is equipped with sensors to detect faulty or incomplete nozzle pressing. It can automatically reject such cans, ensuring only properly sealed products move forward in the filling line.

Q: What maintenance is required for the machine?

A: Regular maintenance includes cleaning the machine, inspecting and replacing worn-out parts, and ensuring proper lubrication. Refer to the manufacturer's guidelines for specific maintenance instructions.