1. Paint

Spray paint, also known as aerosol paint, typically consists of an aerosol can, valve, contents (paint), and propellant. It involves high-pressure filling of paint processed through specialized methods for convenient application, also referred to as manual spray paint. Spray paints are primarily categorized into oil-based and water-based types. Oil-based paints offer lower production costs, while water-based paints are more environmentally friendly. This article focuses on oil-based paints; water-based paints are covered in a separate article.

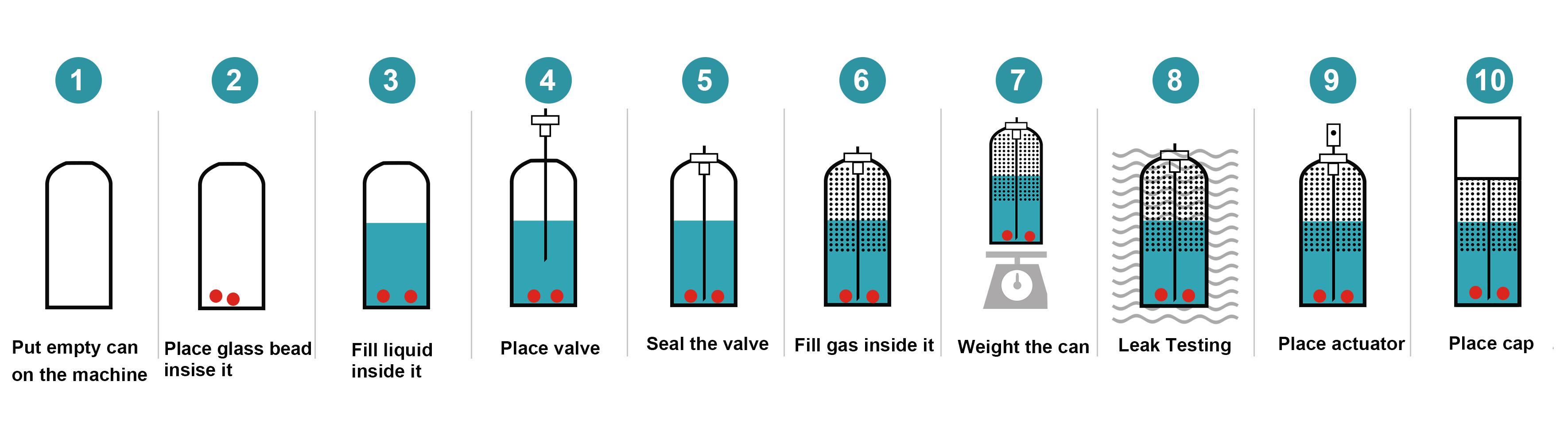

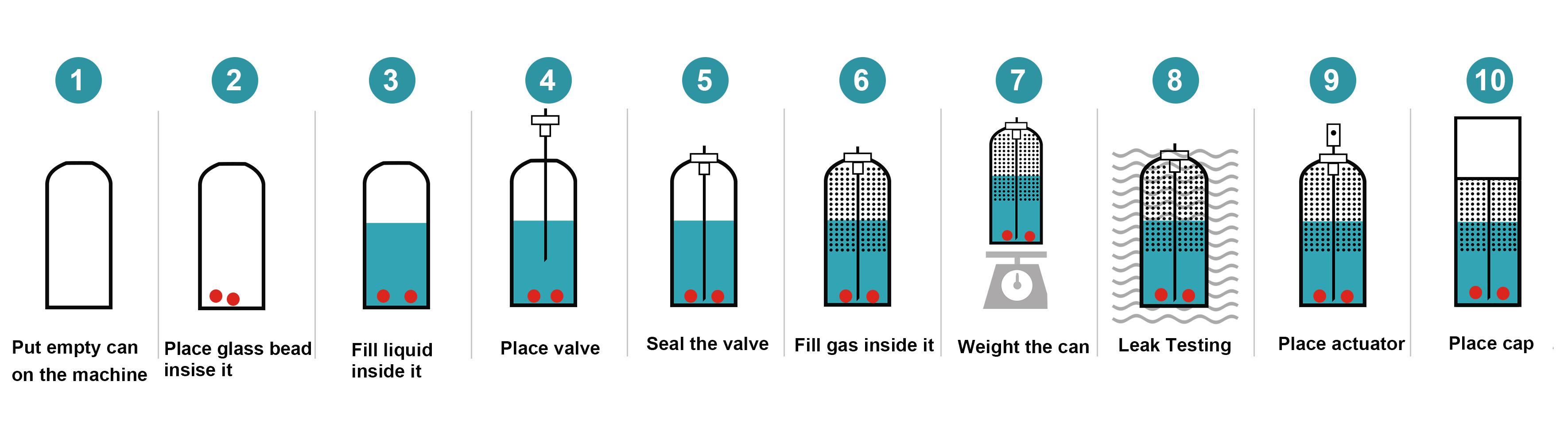

2. Filling Production Process

Oil-based paints generally employ tube valve aerosol packing.

Raw material production → Aerosol feeding → Glass bead placing →liquid filling → Valve inserting→ Sealing → Propellant gas filling → Weight checking → Water bath leak testing → Nozzle fixing → Cap fixing → Coding → Packaging

3. Equipment Introduction and Selection

Insecticide filling equipment is categorized by production scale into small-scale, medium-scale, and large-scale production. Our company offers equipment with different product configurations and models to meet diverse customer output requirements.

(1)  Small-scale Production Machines (Startup/Pilot Production)

Small-scale Production Machines (Startup/Pilot Production)

Suitable for startup teams, new product pilot production, or small-batch custom manufacturing. Semi-automatic equipment features simple operation, low investment costs, and flexible adaptation to diverse orders.

|

|

|

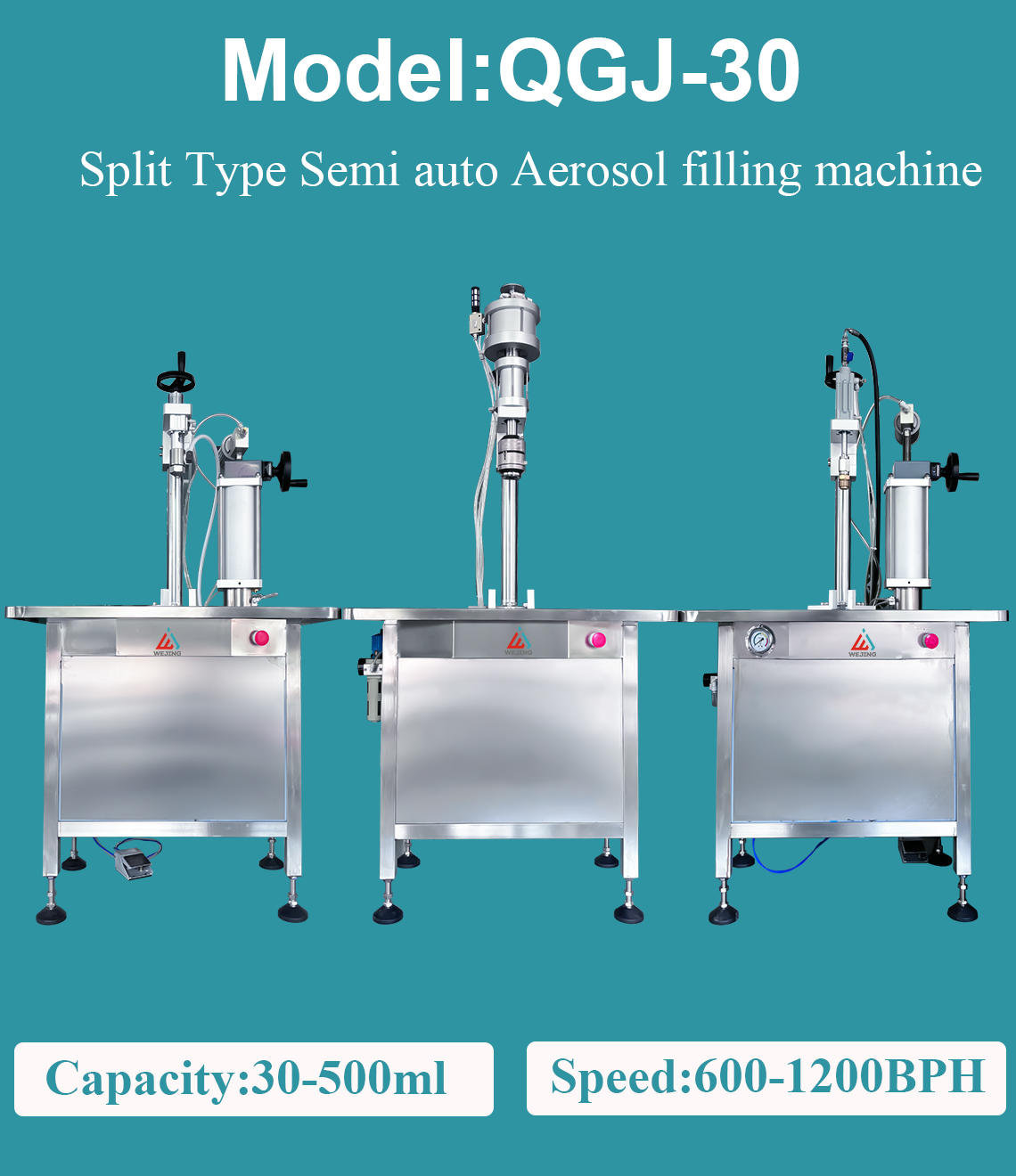

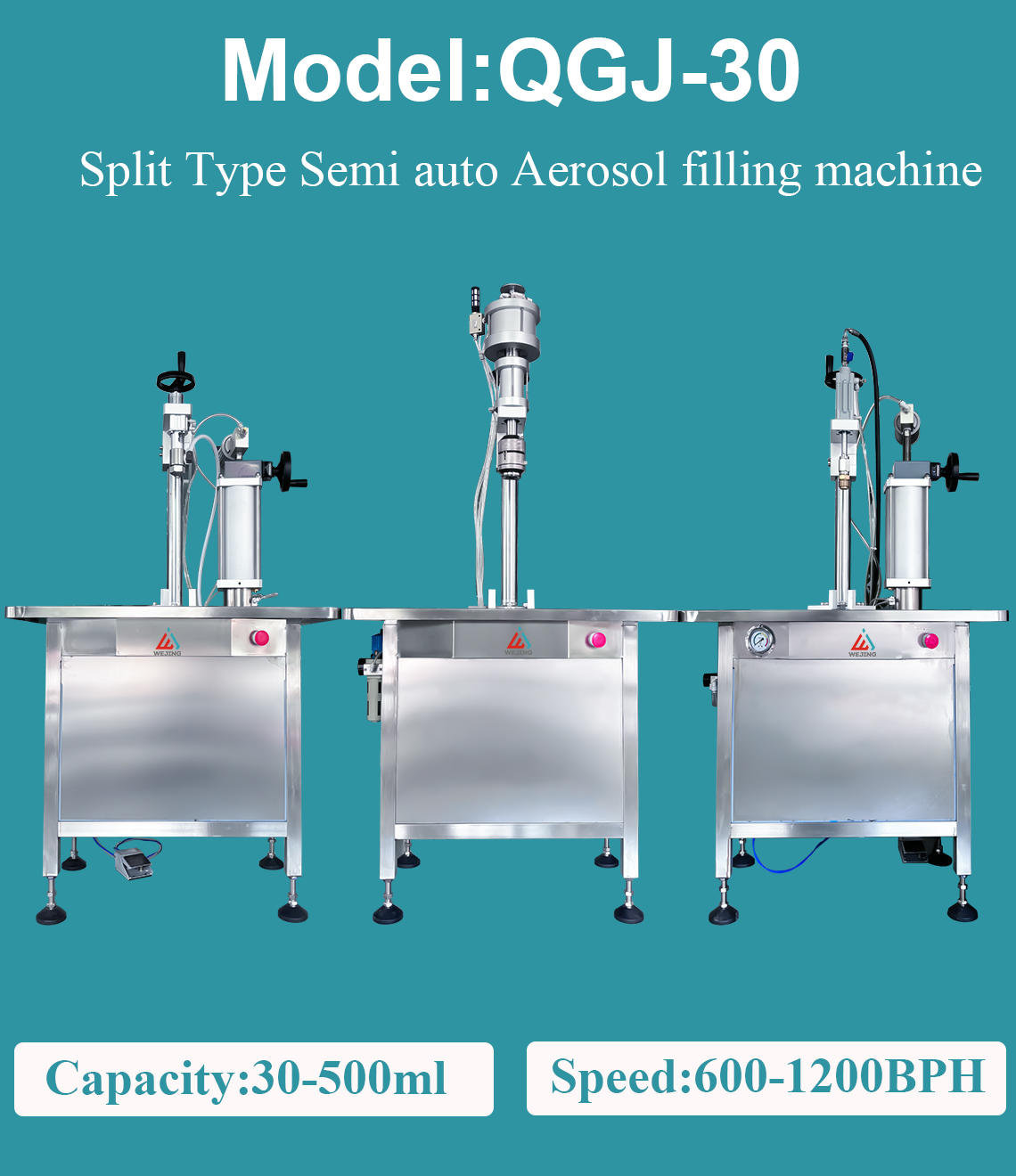

The QGJ-30 Semi-Automatic Aerosol Filling Machine consists of a liquid filling unit, sealing unit, and gas charging unit (including a booster pump).

Highly flexible, fast filling speed, high precision (≤±1%),  and easy adjustment for bottle changeovers. and easy adjustment for bottle changeovers. | The QGJS-20 Semi-Automatic 3-in-1 Aerosol Filling Machine integrates three functions—liquid filling, sealing, and gas charging—into a single workstation. A single operator can complete all actions simultaneously with one press of the foot valve.

This standard three-in-one integrated machine offers high integration, saving space and labor while ensuring simple operation. | The QGJV-20 Semi-Automatic 4-in-1 Aerosol Filling Machine integrates liquid filling, valve support, sealing, and gas charging into a single operation, completing all four processes simultaneously with one action.

The integrated valve support process further reduces labor requirements and streamlines the workflow. |

(2) Medium-Sized Production Line (Output Upgrade)

For enterprises with medium-to-small-scale output upgrade needs, we recommend the QGJ70 Automatic Aerosol Paint Filling Production Line. This line offers filling capacities of 30-1200ml (customizable) at speeds of 60-70 cans per minute.

For enterprises with medium-to-small-scale output upgrade needs, we recommend the QGJ70 Automatic Aerosol Paint Filling Production Line. This line offers filling capacities of 30-1200ml (customizable) at speeds of 60-70 cans per minute.

The system comprises a turntable-type four-head liquid filler, turntable-type sealing and gas-charging machine, automatic valve applicator, automatic nozzle presser, coding machine, and conveyor belt. It can be integrated with water bath leak detection, automatic weighing machine, and automatic capping. All core processes are mechanized, significantly reducing labor requirements. This setup is highly suitable for medium-scale aerosol manufacturers entering production.

(3)  Large-Scale Production Line (Stable Mass Production)

Large-Scale Production Line (Stable Mass Production)

For enterprises with stable sales channels, we recommend the QGJ120 Automatic Aerosol Paint Filling Production Line. This line handles filling volumes of 30-1200ml (customizable) at speeds of 90-120 cans per minute, substantially boosting output.

The QGJ-120 Automatic aerosol filling production line is composed of can feeding machine,glass bead placing machine. two index ten heads liquid filing machine,two index valve inserting &crimping machine, two index ten heads gas filling machine, automatic valve inserting machine, automatic weighing checker, automatic water-bath leakage tester, automatic printer, automatic actuator presser, automatic cap presser and conveyor All processes are mechanized, significantly reducing labor requirements and making it highly suitable for aerosol manufacturers engaged in large-scale production.