Product Advantage:

1. Enhanced Homogenization: The Homogeneous Vacuum Mixing Emulsifier excels in achieving thorough homogenization of ingredients. Its advanced technology ensures the complete integration of substances, resulting in uniform compositions and consistent product quality.

2. Controlled Particle Size Distribution: With precise control over process parameters, the emulsifier enables the manipulation of particle size distribution. This control is crucial in industries like cosmetics and pharmaceuticals, where specific particle sizes are required to achieve desired product properties and performance.

3. Increased Stability of Active Ingredients: The vacuum environment provided by the emulsifier helps maintain the stability of active ingredients. By minimizing exposure to oxygen and other external factors, the emulsifier ensures the preservation of the potency and effectiveness of sensitive compounds, extending their shelf life.

4. Efficient Dispersion of Additives: The emulsifier facilitates the efficient dispersion of additives, such as colorants, flavors, and functional ingredients. Its powerful mixing action ensures even distribution throughout the product matrix, enhancing sensory attributes and providing a consistent consumer experience.

5. Improved Texture and Mouthfeel: The emulsifier's ability to create finely dispersed emulsions results in improved texture and mouthfeel of products. Whether it's achieving a smooth and creamy texture in a lotion or a velvety consistency in a sauce, the emulsifier enhances sensory aspects, elevating the overall product experience.

Technical Parameters:

Model | Capacity(L) | Mixing | Homogenizing |

|

| Power(kw) | Speed(r/min) | Power(kw) | Speed(r/min) |

WJ-LTP50 | 50 | 0.75 | 0-60 | 1.5 | 0-3000 |

WJ-LTP100 | 100 | 1.5 | 0-60 | 3 | 0-3000 |

WJ-LTP200 | 200 | 2.2 | 0-60 | 4 | 0-3000 |

WJ-LTP300 | 300 | 3 | 0-60 | 7.5 | 0-3000 |

WJ-LTP500 | 500 | 4 | 0-60 | 11 | 0-3000 |

WJ-LTP1000 | 1000 | 5.5 | 0-60 | 15 | 0-3000 |

WJ-LTP2000 | 2000 | 7.5 | 0-60 | 18.5 | 0-3000 |

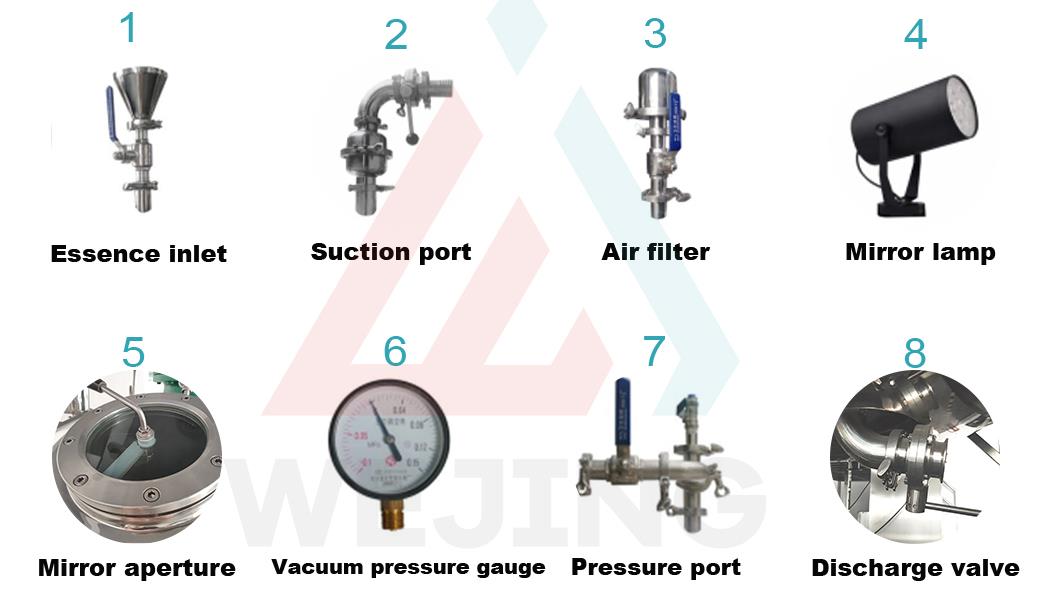

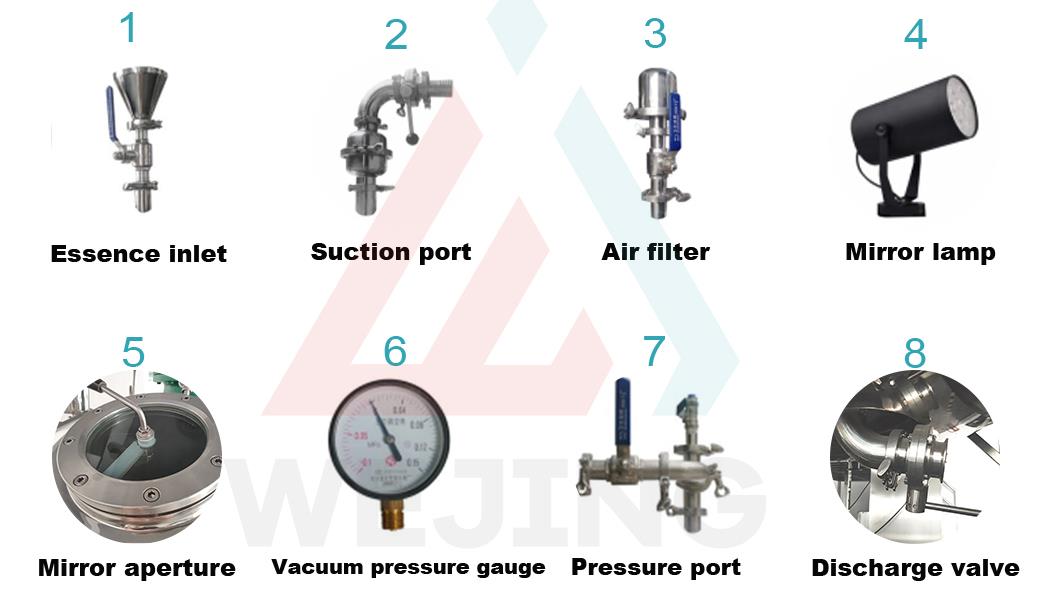

Detailed Images:

Product Uses:

1. Dairy Industry: The Homogeneous Vacuum Mixing Emulsifier is essential for producing emulsified dairy products like butter, cream, and yogurt, ensuring smooth texture, improved stability, and enhanced mouthfeel.

2. Confectionery Industry: This emulsifier is used in the production of emulsified confectionery products like chocolates, fillings, and creams, ensuring consistent texture, flavor distribution, and prolonged shelf life.

3. Pet Food Industry: It finds application in producing emulsified pet food products such as gravies and sauces, ensuring uniform distribution of nutrients, enhanced palatability, and improved digestibility.

4. Industrial Lubricants: The emulsifier is utilized in the manufacturing of emulsified lubricants, enabling optimal dispersion of additives, improved lubrication performance, and extended equipment lifespan.

5. Textile Industry: It plays a vital role in the production of emulsified textile auxiliaries, ensuring uniform application, enhanced dye absorption, and improved fabric properties.

Working principle:

The material is sucked into the working chamber by the strong centrifugal force generated by the high-speed rotation of the rotor. In the gap between the stator and rotor, the material is subjected to shear action, causing dispersed particles or droplets to break. This process mainly relies on extremely high shear force.

Product Operate Guide:

1. Product Customization: Adapt the emulsifier settings and formulation to meet specific customer requirements, such as texture, viscosity, or ingredient compatibility, ensuring tailored products that cater to distinct market preferences.

2. Scale-up Capability: Evaluate the emulsifier's scalability to accommodate larger production volumes, ensuring a seamless transition from laboratory-scale to commercial-scale manufacturing without compromising product quality or process efficiency.

3. Process Automation: Explore opportunities to automate certain tasks or integrate the emulsifier into a larger automated production line, enhancing productivity, reducing manual labor, and minimizing human error.

4. Cross-Industry Applications: Identify potential applications of the emulsifier beyond its primary industry, exploring opportunities in diverse sectors such as pharmaceuticals, personal care, food, or even innovative industries like 3D printing.

5. Research and Development: Allocate resources to research and development activities aimed at continuous improvement, innovation, and staying at the forefront of emulsification technology, ensuring a competitive edge and meeting evolving market demands.

FAQ:

Q: Is it easy to clean and maintain a homogeneous vacuum mixing emulsifier?

A: Yes, most homogeneous vacuum mixing emulsifiers are designed with easy disassembly and cleaning in mind. Regular maintenance, such as cleaning and lubrication of components, helps ensure optimal performance and longevity.

Q: What safety features are incorporated into a homogeneous vacuum mixing emulsifier?

A: Safety features may include emergency stop buttons, safety interlocks, overload protection, and motor overheating protection. Always follow the manufacturer's guidelines and implement proper safety protocols.

Q: Can a homogeneous vacuum mixing emulsifier be customized for specific product requirements?

A: Yes, some manufacturers offer customization options to meet specific product requirements, such as vessel size, material compatibility, control systems, or additional features based on customer needs.

Q: What quality control measures are in place during emulsification?

A: Quality control measures may include periodic sampling and testing of emulsions to assess parameters like viscosity, particle size, stability, pH, and other relevant quality indicators to ensure consistency and compliance with desired specifications.

Q: Are there any additional accessories or components required for operating a homogeneous vacuum mixing emulsifier?

A: Additional accessories may include temperature probes, jacketed vessels for heating or cooling, sight glasses for visual inspection, and specialized tools for cleaning and maintenance. These can vary based on specific emulsifier models and application requirements.