Product Advantage:

1. High Accuracy: The automatic filling machine ensures precise fills, minimizing product waste and ensuring consistent packaging quality.

2. Quick Changeover: The machine allows for fast and easy adjustments, facilitating rapid transitions between different products or container sizes, optimizing production efficiency.

3. Multi-Functionality: With customizable features, the machine can handle various filling techniques, such as volumetric, gravity, or piston filling, providing versatility for diverse product requirements.

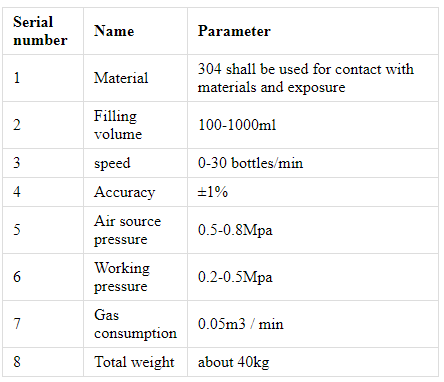

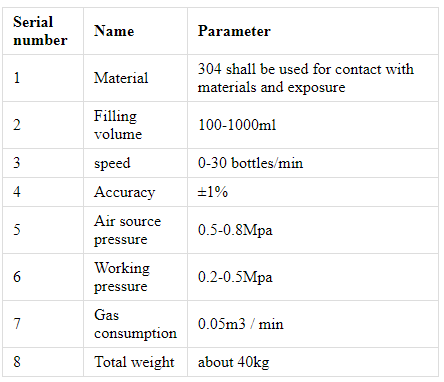

Technical Parameters:

Product Uses:

1. Home Care Products: The automatic filling machine is commonly used for filling laundry detergents, fabric softeners, dishwashing liquids, and other household cleaning products into bottles, ensuring convenient and efficient packaging for consumers.

2. Agricultural Industry: It finds application in filling pesticides, fertilizers, plant nutrients, and crop protection chemicals into containers, facilitating precise and controlled distribution for agricultural purposes.

3. Pet Care Products: The filling machine is utilized for filling pet shampoos, conditioners, grooming products, and veterinary medicines into bottles or containers, catering to the needs of the pet care industry.

4. Paints and Coatings: It is employed for filling paints, varnishes, coatings, and adhesives into cans, pails, or drums, ensuring accurate measurements and efficient packaging in the paint and coatings industry.

5. Industrial Lubricants: The automatic filling machine is used for filling industrial lubricants, oils, greases, and coolants into containers or drums, serving the needs of manufacturing, machinery, and automotive industries.

Product Operate Guide:

1. Safety Precautions: Before operating the automatic filling machine, ensure that all safety guards are in place and operators are trained on proper machine handling and emergency procedures to maintain a safe working environment.

2. Product Preparation: Prepare the product to be filled by ensuring it is properly mixed, filtered, and ready for the filling process. Connect the necessary supply lines for product transfer to the machine.

3. Container Handling: Ensure a steady supply of empty containers is available for continuous filling. Monitor the container feed system and make adjustments as needed to maintain a smooth and uninterrupted flow.

4. Maintenance and Cleaning: Regularly clean and maintain the machine to prevent product contamination and equipment malfunction. Follow the manufacturer's guidelines for routine maintenance tasks such as lubrication and component inspection.

5. Troubleshooting: Familiarize yourself with common issues that may arise during operation, such as clogs, misalignments, or sensor errors. Troubleshoot and resolve issues promptly to minimize downtime and optimize productivity.