Product Advantage:

1. Versatile Filling Capability: The automatic filling machine accommodates a wide range of product viscosities, from thin liquids to thick pastes, offering flexibility for diverse manufacturing needs.

2. Quick Changeover: The machine features efficient changeover capabilities, allowing for swift transitions between different products or container sizes, minimizing downtime and maximizing productivity.

3. Hygienic Design: With sanitary construction and easy-to-clean surfaces, the automatic filling machine ensures compliance with stringent hygiene standards, maintaining product integrity and safety.

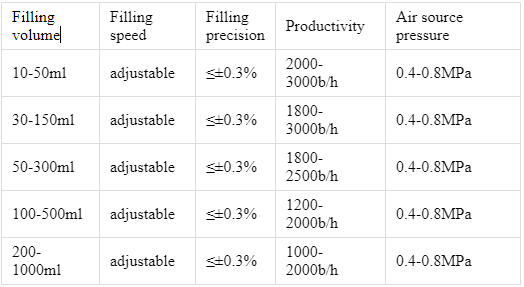

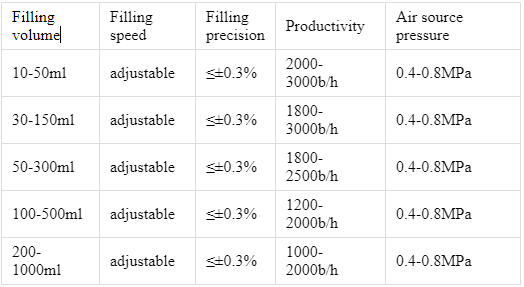

Specification:

Product Uses:

1. Edible Oils: The automatic filling machine is commonly used for filling cooking oils, vegetable oils, olive oils, and other edible oils into bottles, cans, or pouches, providing efficient and leak-proof packaging solutions.

2. Chemical Industry: It finds application in filling industrial chemicals, solvents, acids, and corrosive liquids into drums, barrels, or containers, ensuring safe and accurate handling of hazardous substances.

3. Cleaning and Sanitizing Products: The filling machine is employed for filling disinfectants, sanitizers, detergents, and cleaning solutions into bottles or containers, meeting the demands of the cleaning and janitorial supplies industry.

4. Personal Care and Beauty Products: It is utilized for filling lotions, creams, serums, facial masks, and hair care products into tubes, jars, or bottles, ensuring precise and consistent packaging for the personal care market.

Product Operate Guide:

1. Material Handling: Properly handle and store the raw materials used in the filling process, ensuring they are labeled, stored in designated areas, and protected from contamination or damage.

2. Machine Calibration: Regularly calibrate the automatic filling machine to ensure accurate fill volumes, adjust for any variations or drifts, and maintain consistent performance throughout the production cycle.

3. Batch Control: Implement a robust batch control system to track and record each production batch, including timestamps, product details, and relevant parameters, ensuring traceability and quality control.

4. Sanitization Procedures: Establish and follow strict sanitization procedures for the filling machine, including regular cleaning, disinfection, and sterilization of contact surfaces to prevent cross-contamination and ensure product safety.

5. Operational Efficiency: Continuously optimize the filling process by identifying areas for improvement, such as reducing downtime, minimizing product loss, and streamlining workflow, to enhance overall operational efficiency and productivity.