1. Insecticides

Insecticide aerosols are convenient household pest control products comprising three core components: pyrethroid pesticide active ingredients for rapid insect knockdown; solvents (e.g., kerosene, ethanol) to dissolve and carry the active ingredients; and propellants (e.g., LPG) to provide pressure for uniform spray dispersion. These components work synergistically to effectively eliminate flying and crawling pests, making them widely applicable in household environments.

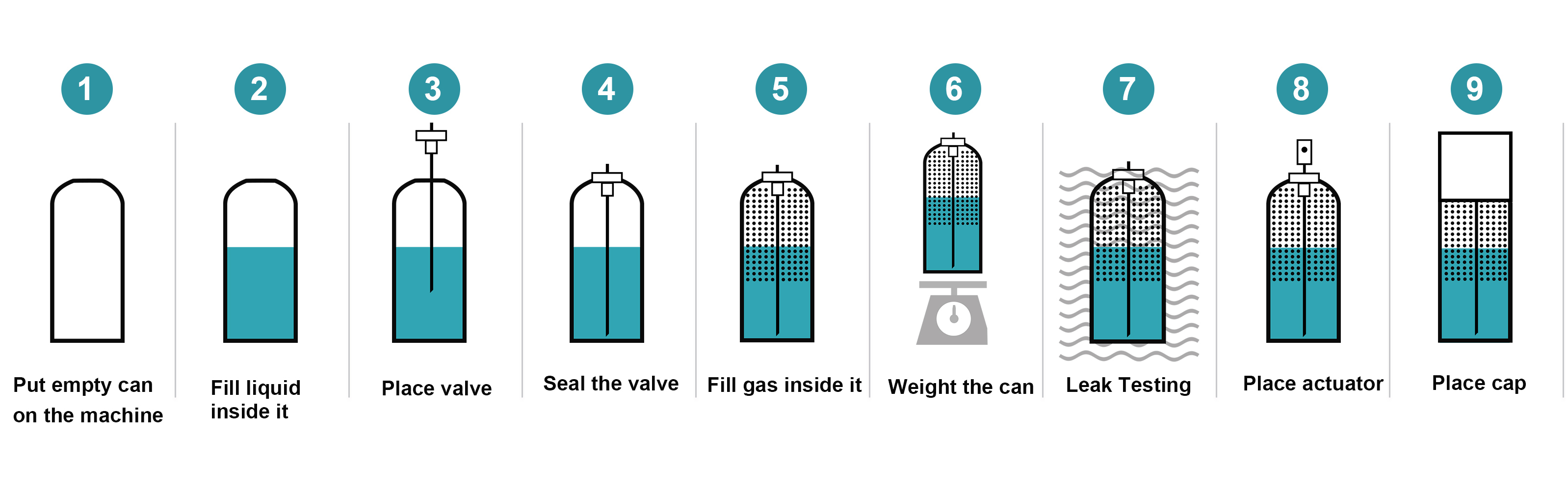

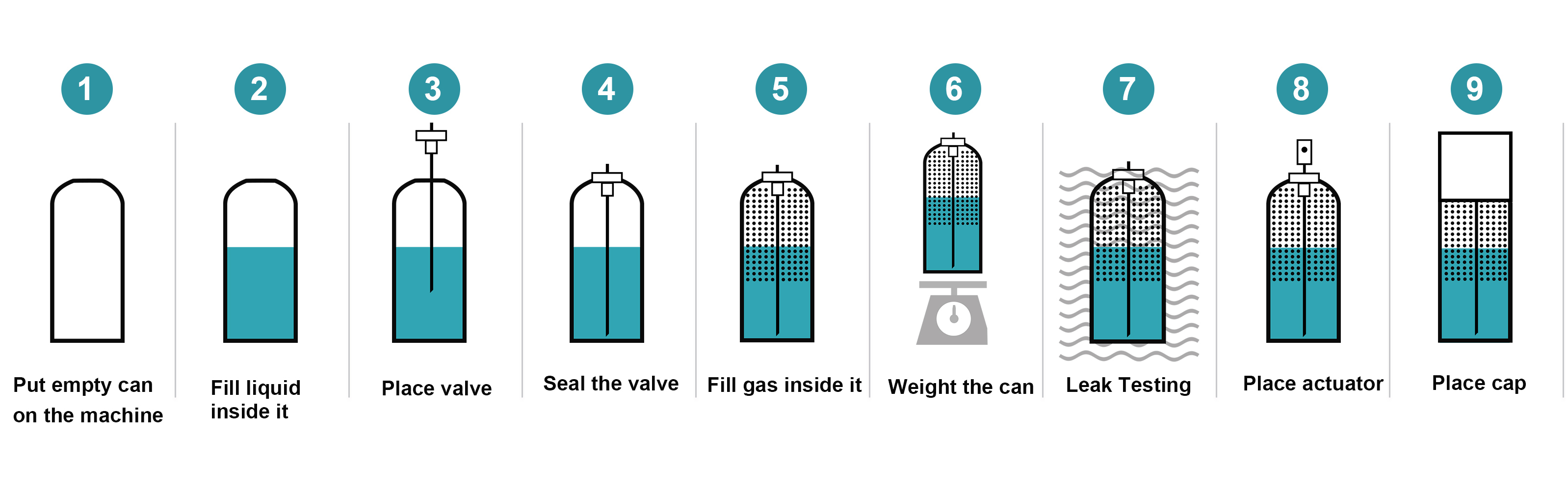

2. Filling Production Process

Raw material production → Aerosol feeding → liquid filling → Valve inserting→ Sealing → Propellant gas filling → Weight checking → Water bath leak testing → Nozzle fixing → Cap fixing → Coding → Packaging

3. Equipment Introduction and Selection

Insecticide filling equipment is categorized by production scale into small-scale, medium-scale, and large-scale production. Our company offers equipment with different product configurations and models to meet diverse customer output requirements.

(1)  Small-scale Production Machines (Startup/Pilot Production)

Small-scale Production Machines (Startup/Pilot Production)

Suitable for startup teams, new product pilot production, or small-batch custom manufacturing. Semi-automatic equipment features simple operation, low investment costs, and flexible adaptation to diverse orders.

|

|

|

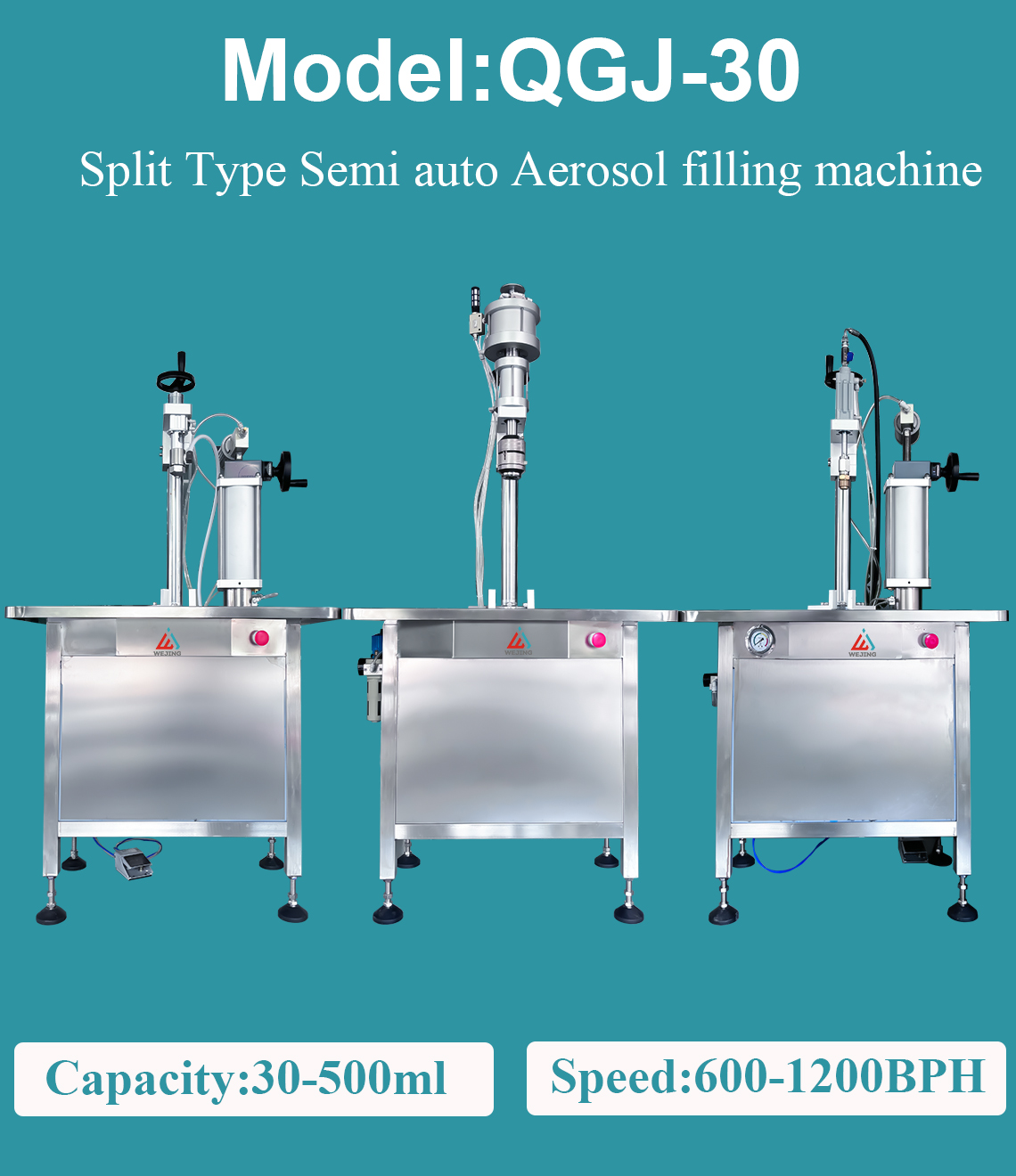

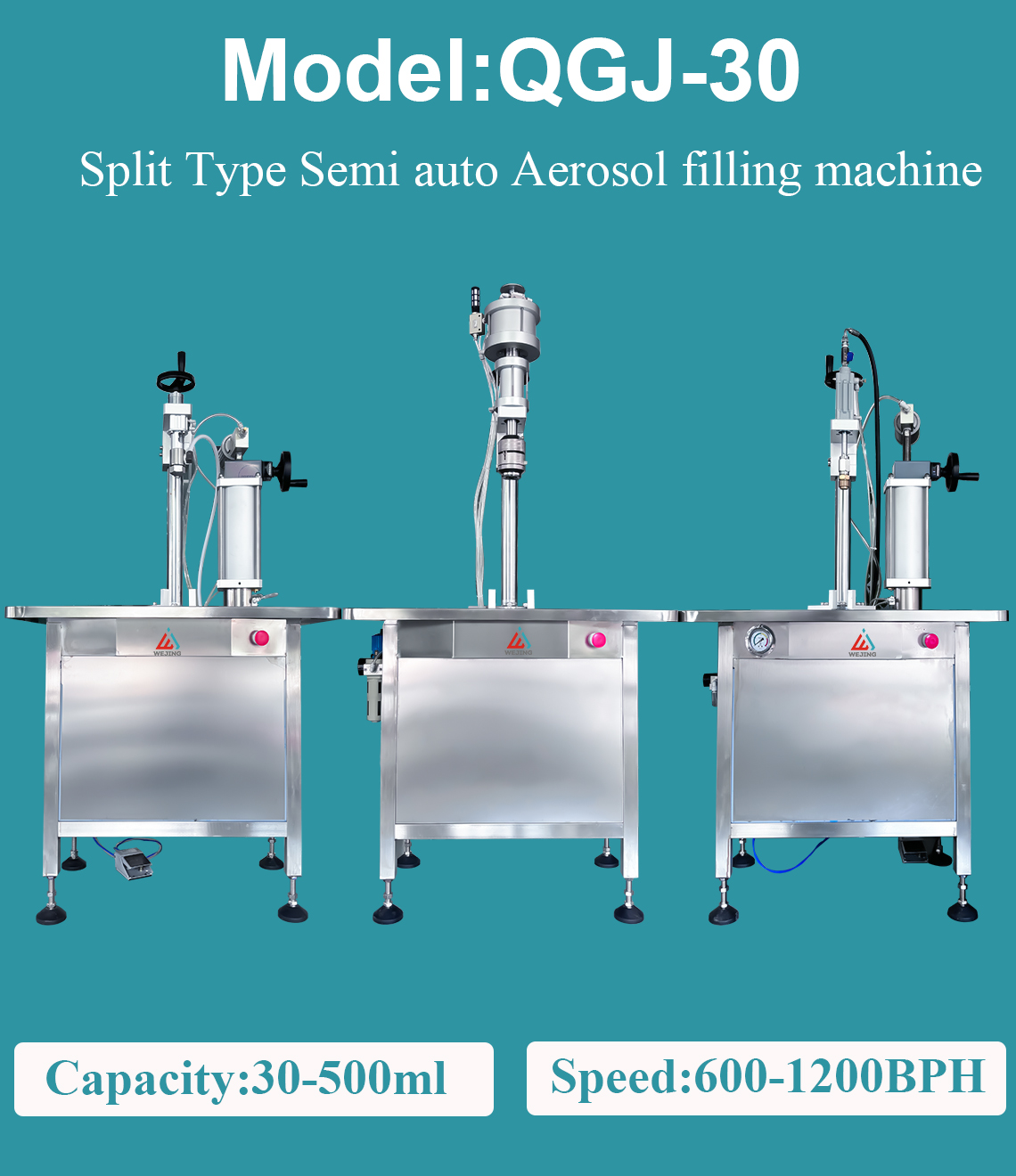

The QGJ-30 Semi-Automatic Aerosol Filling Machine consists of a liquid filling unit, sealing unit, and gas charging unit (including a booster pump).

Highly flexible, fast filling speed, high precision (≤±1%),  and easy adjustment for bottle changeovers. and easy adjustment for bottle changeovers. | The QGJS-20 Semi-Automatic 3-in-1 Aerosol Filling Machine integrates three functions—liquid filling, sealing, and gas charging—into a single workstation. A single operator can complete all actions simultaneously with one press of the foot valve.

This standard three-in-one integrated machine offers high integration, saving space and labor while ensuring simple operation. | The QGJV-20 Semi-Automatic 4-in-1 Aerosol Filling Machine integrates liquid filling, valve support, sealing, and gas charging into a single operation, completing all four processes simultaneously with one action.

The integrated valve support process further reduces labor requirements and streamlines the workflow. |

(2) Medium-Scale Production Line (Stable Mass Production)

Suitable for enterprises with established sales channels requiring continuous batch production. Automated production lines significantly enhance efficiency and ensure stable output.

Suitable for enterprises with established sales channels requiring continuous batch production. Automated production lines significantly enhance efficiency and ensure stable output.

(3)  Large-Scale Production Lines

Large-Scale Production Lines

Designed for established brands and major OEM/ODM manufacturers, these lines handle massive order volumes and sustained continuous production, delivering unparalleled manufacturing efficiency.