QGJ-70 Automatic aerosol filling production line is composed of ,index type four heads liquid filling machine, index type crimping head & four heads gas filling machine, conveyor, automatic valve inserting machine, automatic weighing checker, , automatic printer, automatic actuator presser, automatic cap presser.it also could equipped with automatic water-bath leakage tester

|

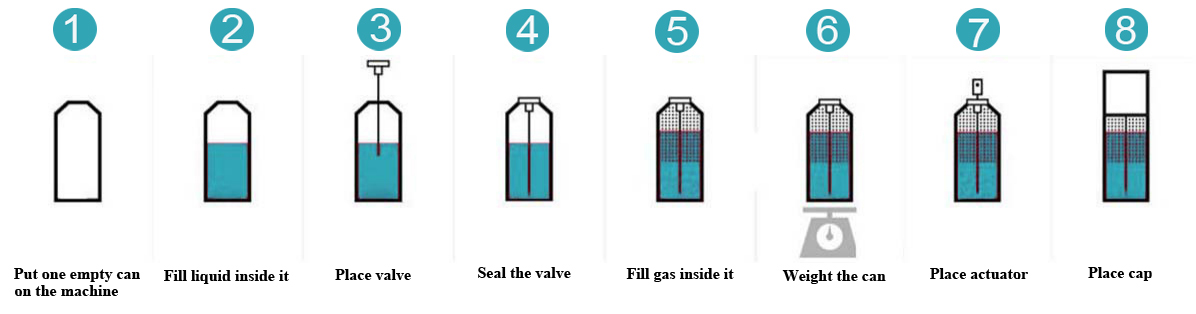

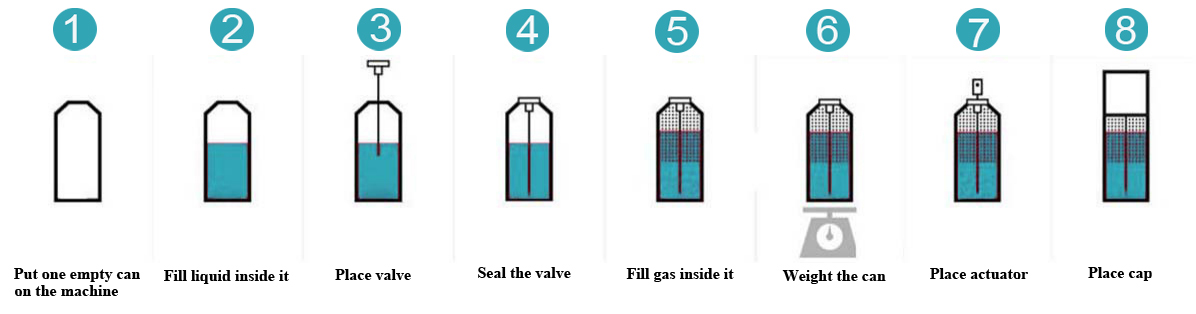

Workflow

NO. | Name | Description |

1 | Filling capacity | 60-70 cans/min |

2 | Filling volume | 10-1200ml |

3 | Filling accuracy | ≤±1% |

4 | Applicable cans diameter | 35 - 70mm( can be customized) |

5 | Applicable cans height | 80 - 350mm( can be customized) |

6 | Applicable valve | 1 inch ( can be customized) |

7 | Working pressure | 0.6 - 0.8Mpa |

8 | Max gas consumption | 5 m3/min |

9 | Power | 7.5KW |

10 | Material | SS304 ( some parts can be SS316) |

11 | Warranty | 2 years |

QGJ-120 Automatic aerosol filling production line is composed of two index ten heads liquid filing machine,two index valve inserting and crimping machine, two index ten heads gas filling machine, it also could equipped with automatic valve inserting machine, automatic weighing checker, automatic water-bath leakage tester, automatic printer, automatic actuator presser, automatic cap

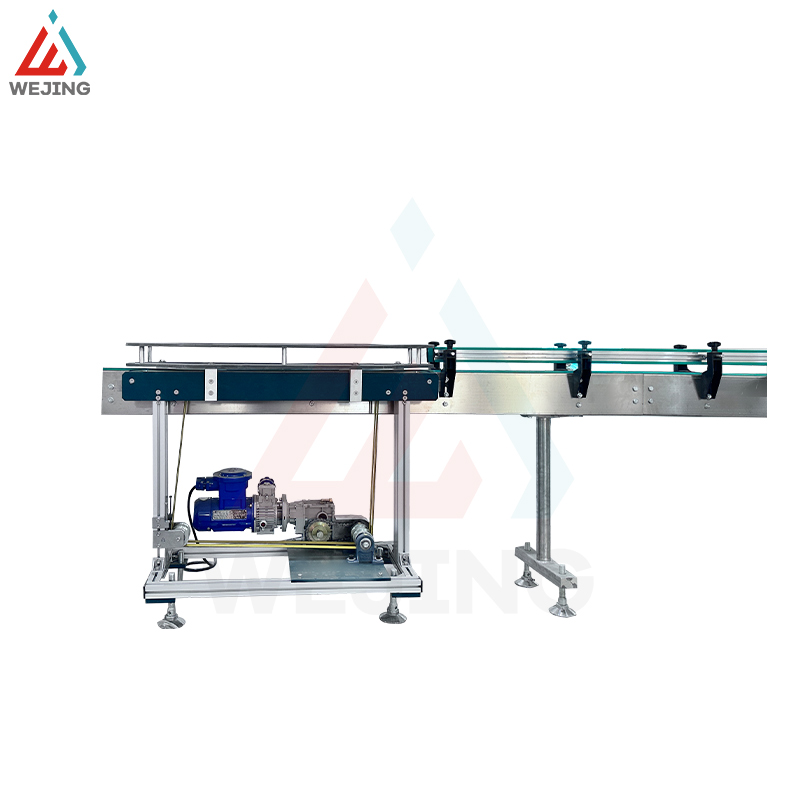

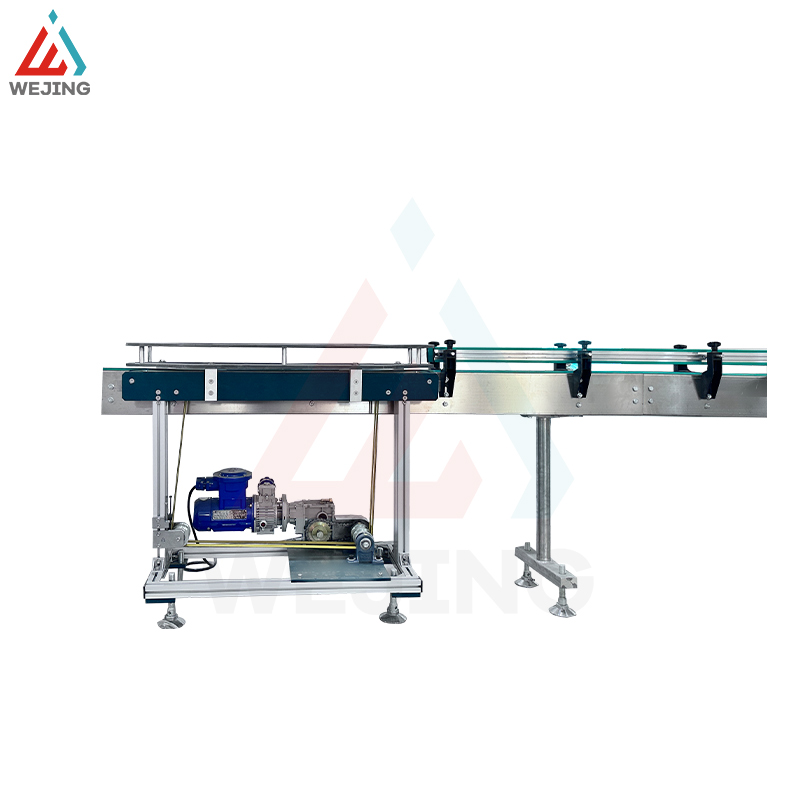

Can Feeding Machine

1.Keep the cans feeding properly and orderly on the conveyor belt.

2.High efficiency and reduce labor intensity.

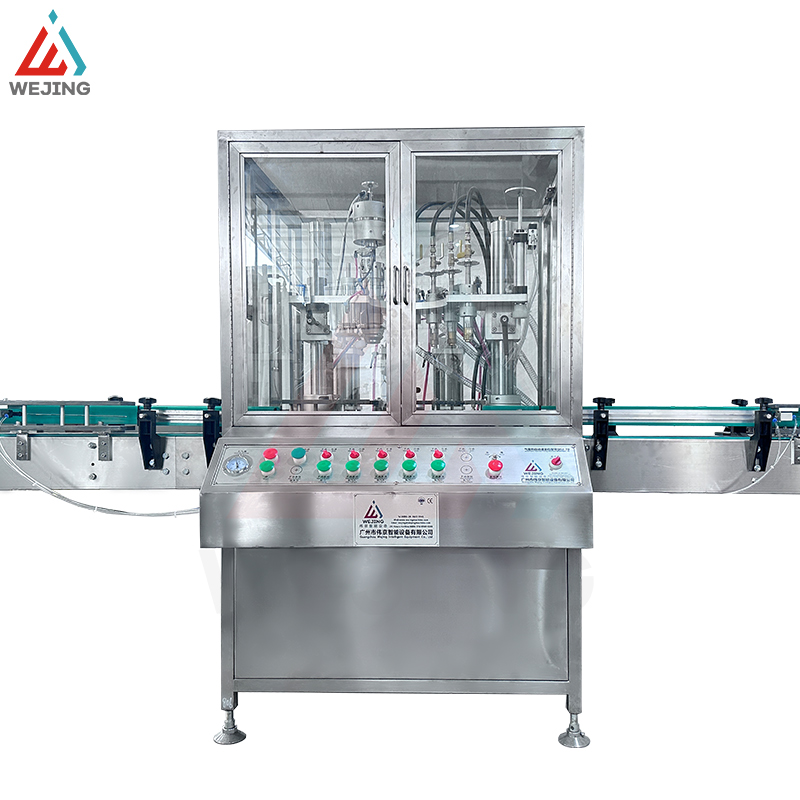

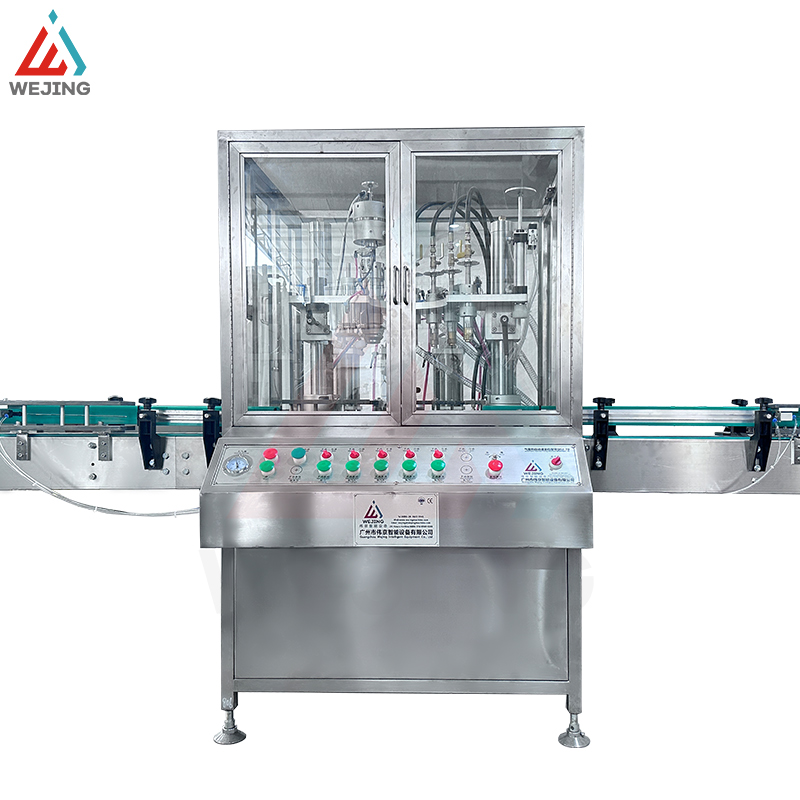

Filling and Valve Inserted Machine

1.Can detecter head. No can,No working

2.4 liquid filling heads

3. Valve inserted

4. Valve centralized

Speed:60-70 cans/min

Filling volume:10-1200 ml ( can be customized)

Gas filling machine

1.Valve centralized

2. Crimping head

3. 4 Gas filling heads

4. Each part can be controlled independently

Speed:60-70 cans/min

Filling volume:10-1200 ml ( can be customized)

Weight checking machine

Electronic weight checking machine is used for online weight inspection of each can inaerosol production line.

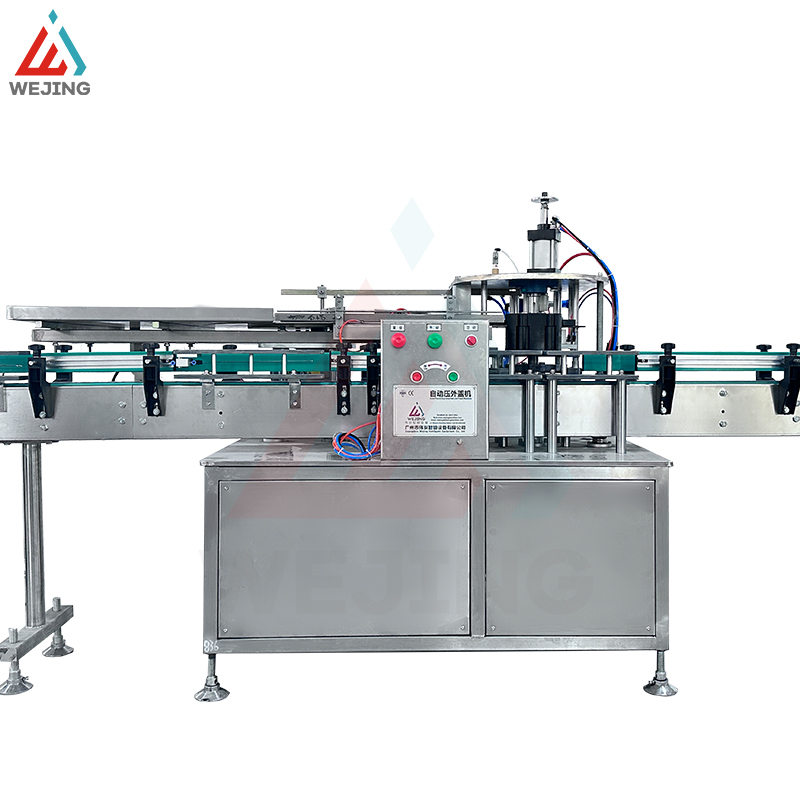

Auto Actuator Pressing Machine

Auto actuator presser machine is used for the installation of spray nozzle of aerosol products.

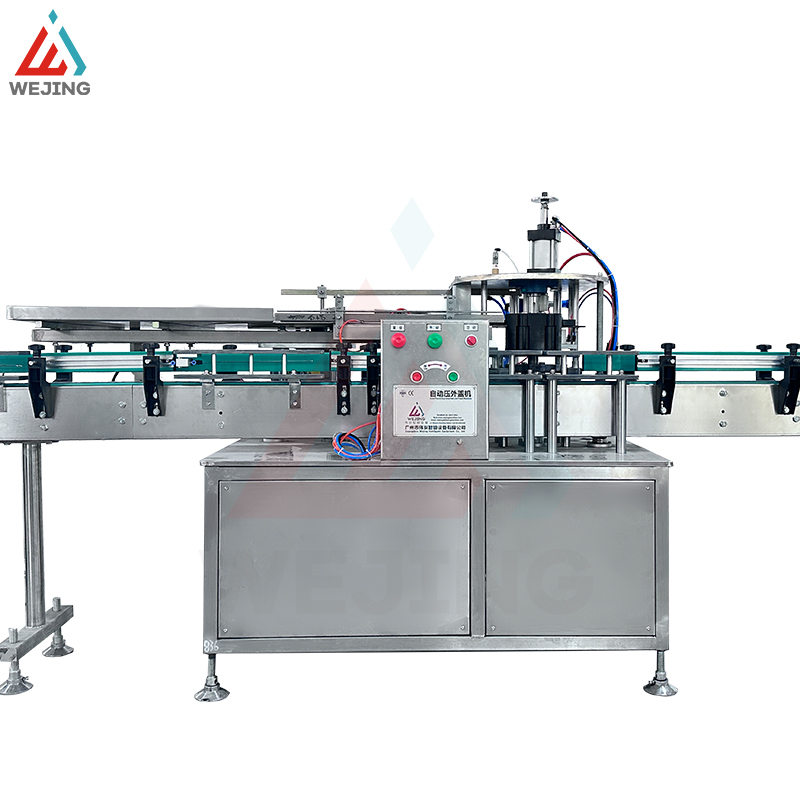

Cap Pressing Machine

Auto security cap presser machine is used for the installation of spray security cap of aerosol products

Aerosol can Ink-jet Belt

Printing product traceability information, clear and durable marking.

Aerosol can collection table

Collect the aerosol products that have been completed production, to facilitate the subsequent workers packing operation