Product Advantage:

1. Increase an additional air cylinder to make the air supply more stable.

2. Improve the platform to make the operation more convenient.

3. Upgrade the gas pipeline and air pipeline to be more reasonable.

4. Add an extra air cylinder to make the air supply more stable.

Technical Parameters:

Capacity | 600-1200 cans/hr,depending on filing volume |

Liquid filling capacity | 30-500ml(can be choose) |

Gas filling capacity | 30-500ml(can be choose) |

Filling accuracy | ≤±1% |

Applicable can diameter | 40-70mm |

Suitable aerosol can height | 70-300mm |

Air source | 0.5-0.6Mpa |

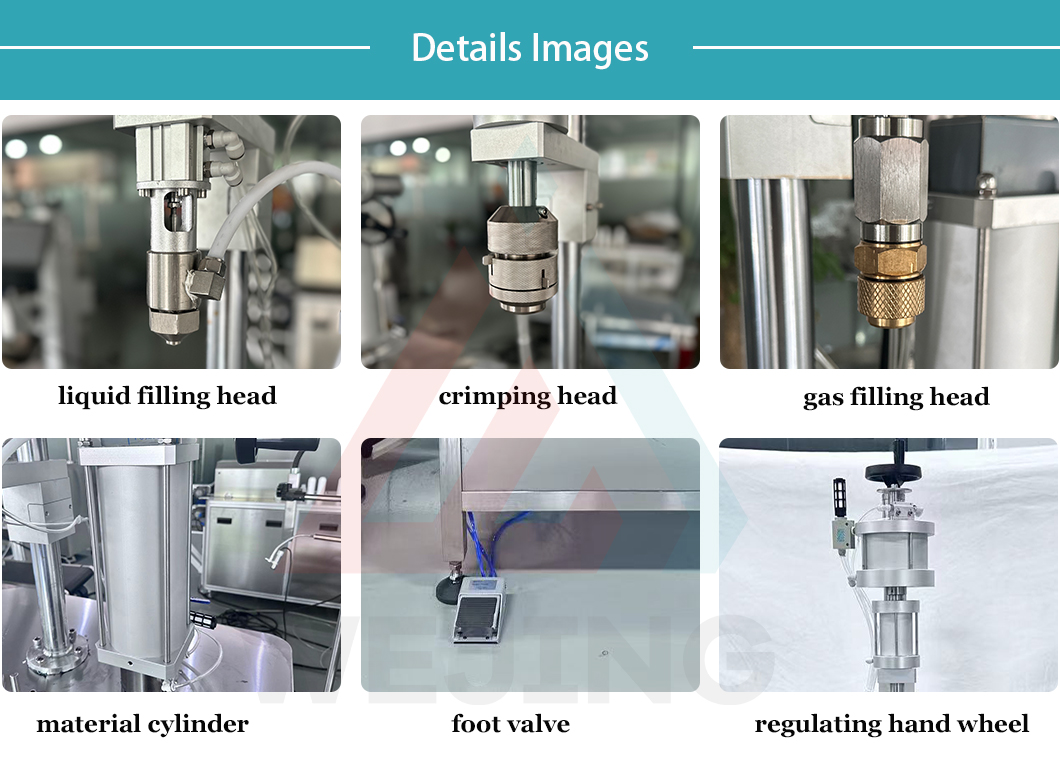

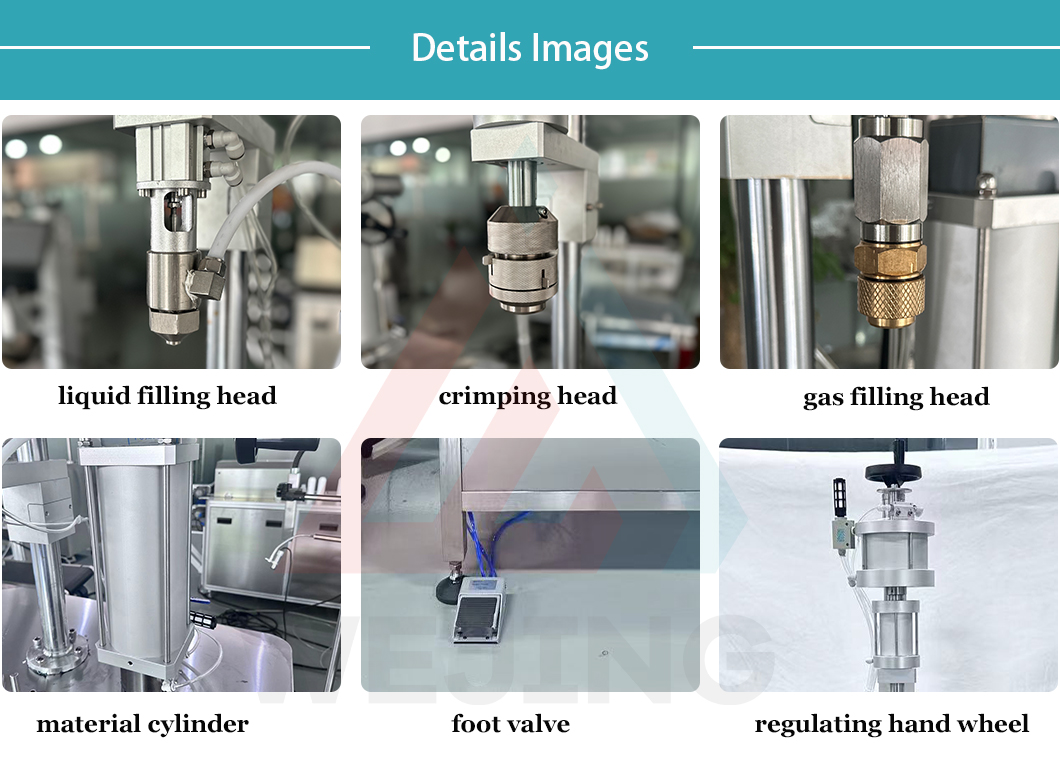

Detail Images:

1. New Upgrade with 4 Highlights: By continuously upgrading and transforming the product, it is more convenient to use and the performance is more stable.

2. three-in-one Filling Machine with three Functions on one Table: The whole machine is composed of four functional parts: liquid filling, crimping, and gas filling.

3. Food Grade 304 Stainless Steel: Safe, non-toxic, durable, and easy to clean.

4. High-efficiency Pneumatic Bottle Pushing: Use the cylinder to automatically push the bottle instead of manual pushing, and it will move forward automatically one by one, which greatly improves the efficiency.

5. Simple Panel for Easy Operation: Four types of equipment switches plus reset button & two pressure gauge displays.

6. Strong Adaptability for Extension to the Production Line: It can be equipped with can arranging machine, valve arranging & inserting machine, crimping machine, capping machine, packing table, and other auxiliary equipment.

Features:

The three-in-one aerosol filling machine integrates the functions of irrigating liquid, sealing, and inflating on one worktable. Only one person is required to operate it sequentially to complete the production of conventional aerosols. This machine is safe, reliable, easy to operate, easy to maintain, and has a small footprint. It is an economical equipment for aerosol product production.

By improving, optimizing, and integrating the original semi-automatic aerosol filling machine, a production line type is integrated. The semi-automatic filling, sealing, and aerating machines are installed on a worktable, and the filler, sealer, and inflator are controlled separately. According to the process sequence, linear production is transferred to complete all actions. This utility model belongs to a semi-automatic applicable device for aerosol product production.

This machine features fast aeration speed, accurate filling capacity, good sealing tightness, and adjustable aeration pressure. It is specially designed for gas single filling and aerosols. It also supports secondary pressurized filling of multi-component gases, such as compressed air, nitrogen, carbon dioxide, and oxygen. The sealing machine and liquid filling machine are optional.

Product Uses:

It is applicable to filling various media and manufacturing various aerosol chemical products. Professional technical design saves labor and time. The filling head is independently controlled and non-mechanical, and the inflatable head is precisely guided, featuring high efficiency and low air consumption. It is widely utilized in experimental household production and chemical laboratory equipment, including aerosol products such as food, medicine, hygiene, automobiles, environmental protection, fire fighting, and daily necessities.

FAQ:

1. What can this machine fill?

It can fill various aerosol products, such as pesticides, perfumes, and paints.

2. Is it easy to operate?

Yes, it is designed to be user-friendly and requires minimal training.

3. How accurate is the filling?

The filling accuracy is high, ensuring consistent product quality.

4. Can it handle different container sizes?

Yes, it is compatible with a range of container sizes.

5. What about maintenance?

Regular maintenance is simple and can be performed by the user.