Product Advantage:

1. High filling accuracy and consistency for quality assurance.

2. Semi-automatic design increases production efficiency.

3. Integrated filling, capping, and labeling for streamlined operation.

4. User-friendly interface for easy operation and control.

5. Compact size and portable, suitable for different production sites.

Technical Parameters:

Capacity | 600-1200 cans/hr,depending on filing volume |

Liquid filling capacity | 30-500ml(can be choose) |

Gas filling capacity | 30-500ml(can be choose) |

Filling accuracy | ≤±1% |

Applicable can diameter | 40-70mm |

Suitable aerosol can height | 70-300mm |

Air source | 0.5-0.6Mpa |

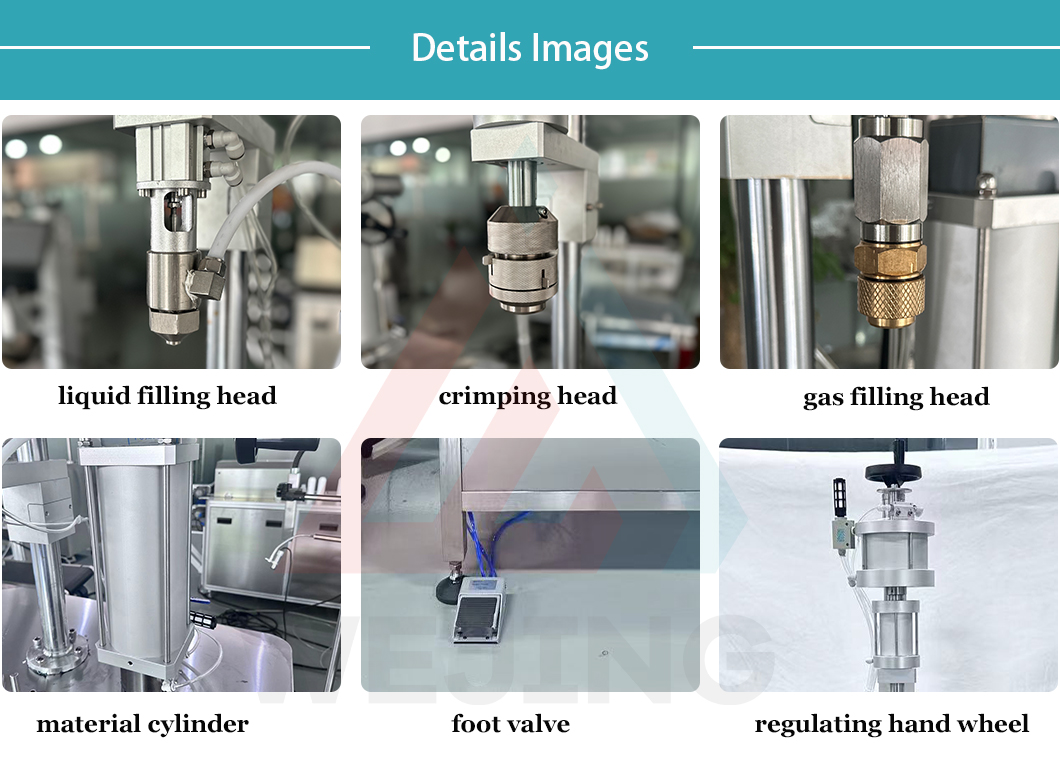

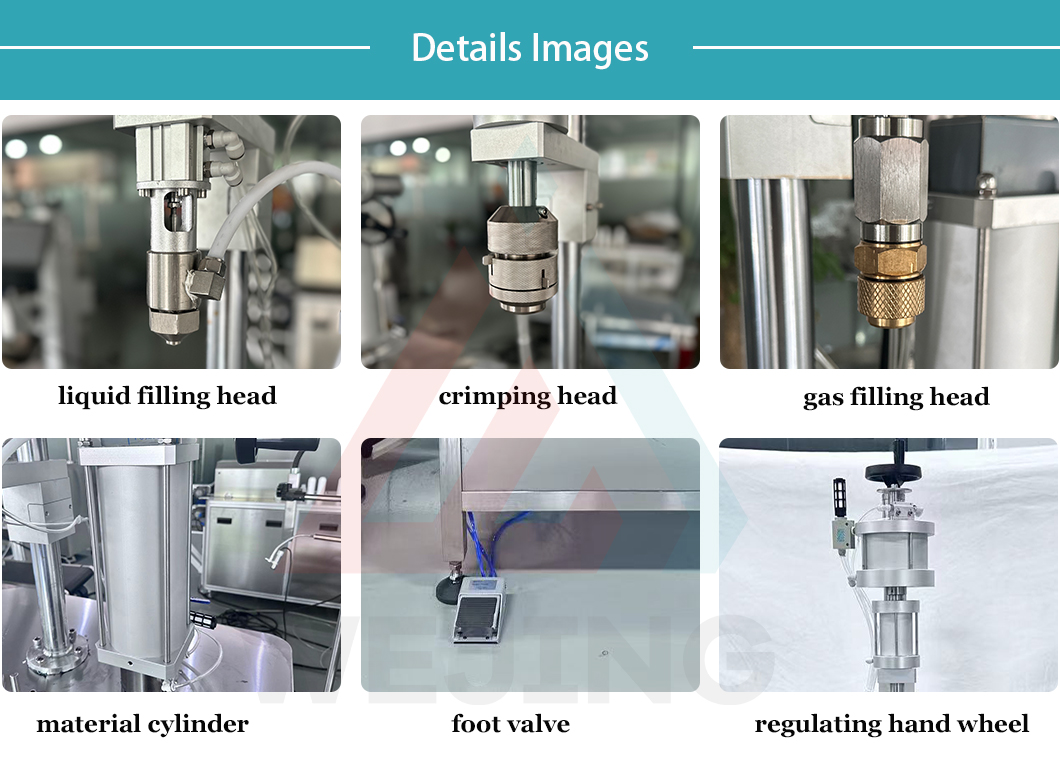

Product Details:

1. The workbench panel is made of matte 304 stainless steel plate, and the material in contact with the raw materials is 304 stainless steel. In special cases, 316 stainless steel can be customized.

2. All other stainless steel materials are 304 type.

Product Uses:

1. Pharmaceutical industry: This machine can be used to fill aerosols with drugs, such as nasal sprays and inhalers.

2. Cosmetics industry: It is suitable for filling aerosols with cosmetic products, such as perfumes and hair sprays.

3. Household chemicals industry: Can be used to fill aerosols with household chemicals, such as air fresheners and insecticides.

4. Automotive industry: This machine can be used to fill aerosols with automotive products, such as tire inflators and lubricants.

5. Industrial sector: Suitable for filling aerosols with industrial chemicals, such as paints and cleaners.

Operational Principle:

1. Aerosol valve insertion: The aerosol valves are automatically inserted into the bottles or cans.

2. Product filling: The filling mechanism fills the desired product into the containers through the valve.

3. Pressure control: The machine controls the pressure inside the containers to ensure proper filling.

4. Weight measurement: It weighs the filled containers to ensure the correct amount of product is dispensed.

5. Capping or sealing: The filled containers are capped or sealed to complete the packaging process.

FAQ:

1. How does the machine control filling accuracy?

The machine uses precise filling mechanisms and weighing systems to ensure accurate filling.

2. Can it handle different types of aerosol containers?

Yes, it is designed to accommodate various types and sizes of aerosol containers.

3. What is the maximum filling speed of the machine?

The filling speed may vary depending on the specific model and configuration.

4. Is the machine easy to operate and maintain?

Yes, it is typically designed for user-friendly operation and requires minimal maintenance.

5. Does the machine come with a warranty?

The warranty period and terms may vary by manufacturer. It is best to check with the supplier.