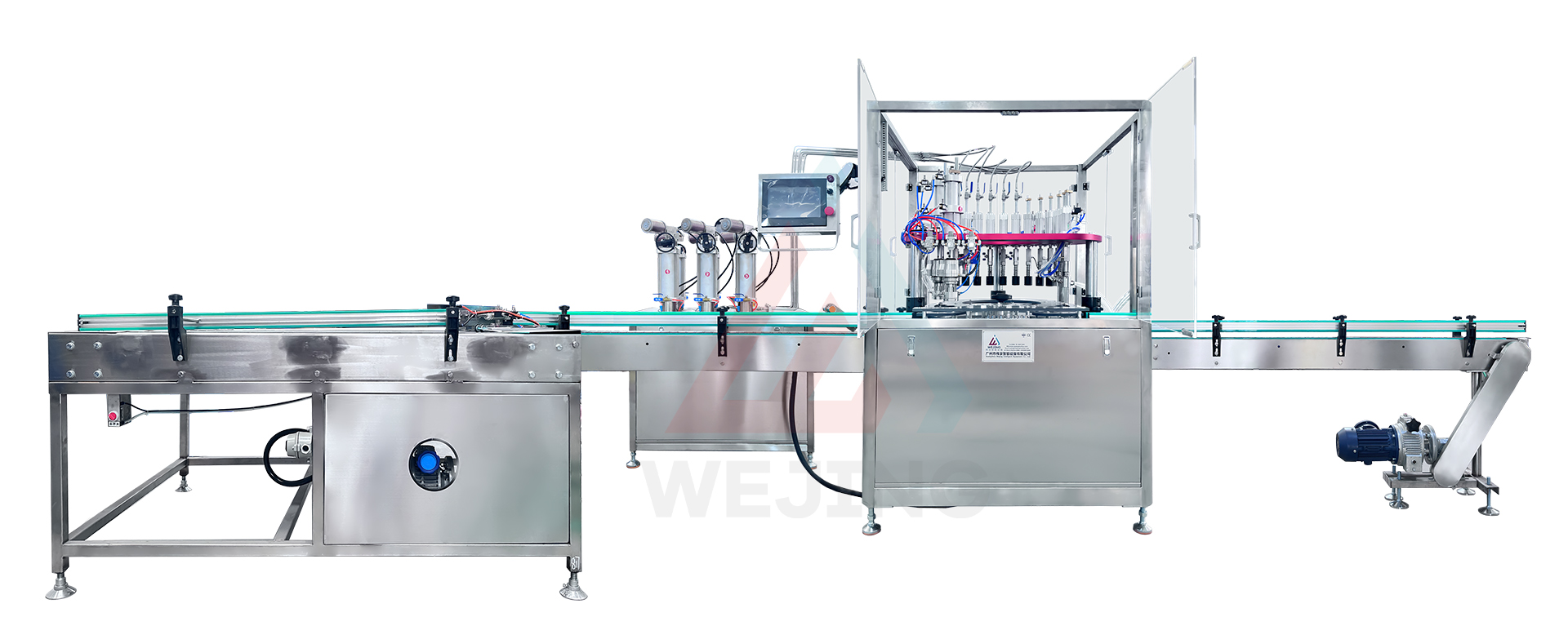

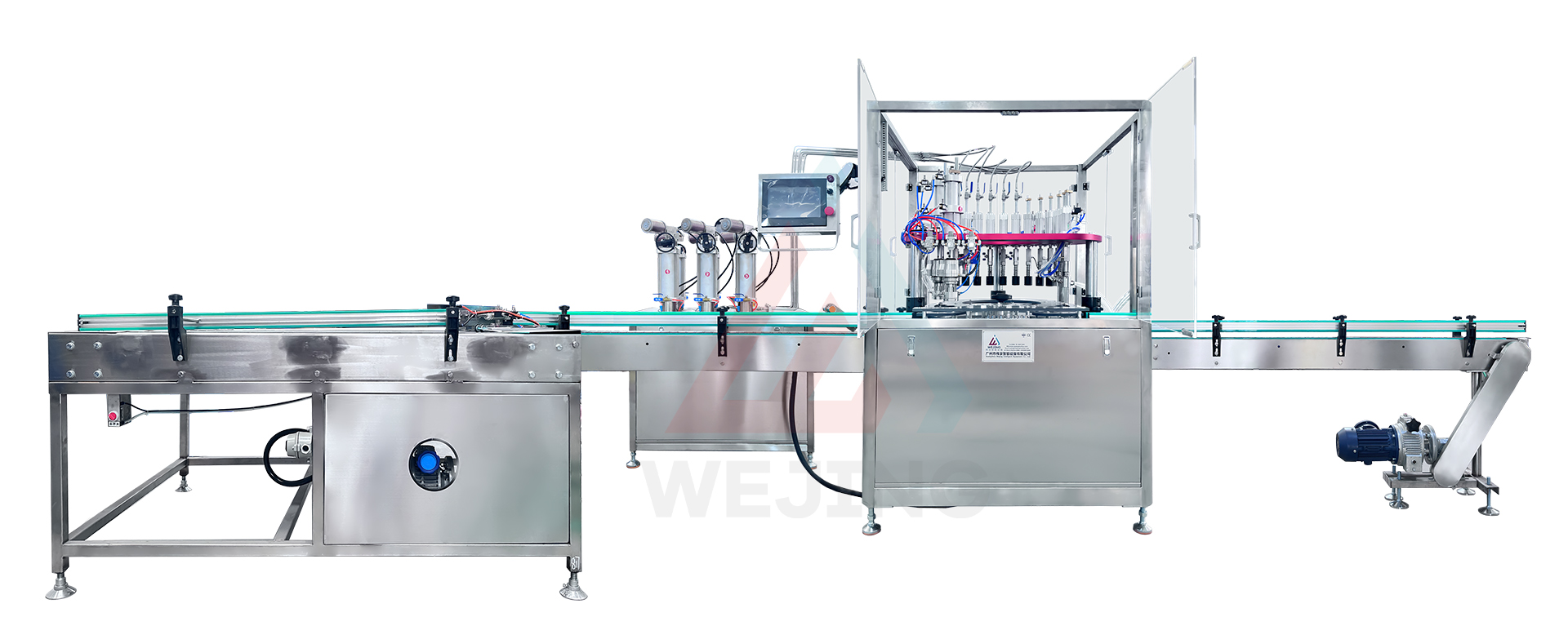

Introducing our WJER-80 High Speed Bov Automatic Aerosol Filling Machine Line, crafted to meet the highest standards of efficiency and precision in aerosol filling processes. As a leading exporter in China, we take pride in delivering cutting-edge technology that ensures seamless production and superior quality output. Trust in our expertise to elevate your manufacturing capabilities and streamline your operations with this advanced filling machine line.

1.Product Introduction

Full-automatic BOV erosol filling machine is suitable for green products (water-based aerosol) packaging, it will be filled with compressed air, sealing, raw material filling into one. At the same time can be equipped with automatic weighing machine, automatic hanging aerosol water bath leakage detection machine, automatic pressure nozzle machine, automatic loading large cap machine, online coding and so on.

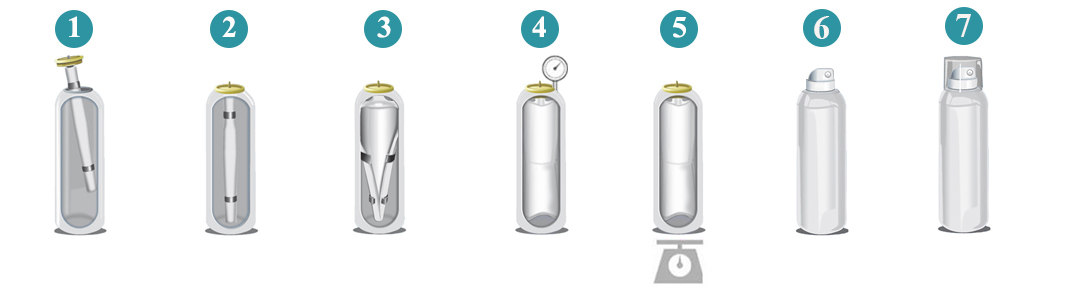

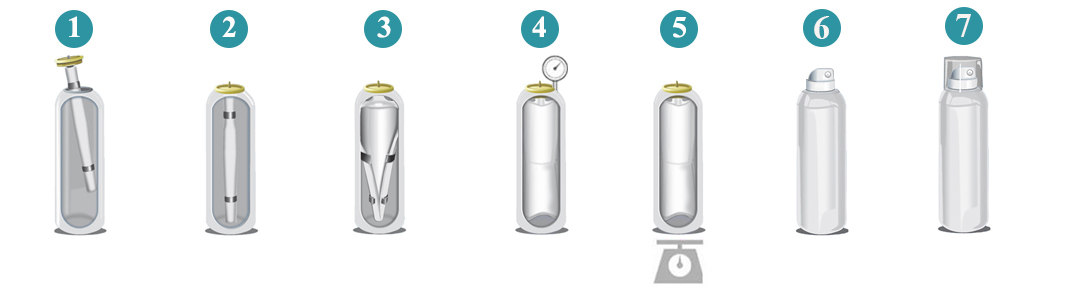

2.BOV Aerosol Process Flow

1) Placing valve

2) Gas filling and seal

3) Liquid Filling

4) Pressure measurement

5)Weight checking

6) Actuator Pressing

7)Outer cap pressing

3.Parameter

1 | Filling capacity | 80-90 cans/min |

2 | Liquid filling volume | 10-300ml/head |

3 | Gas filling accuracy | ≤±1% |

4 | Liquid filling accuracy | ≤±1% |

5 | Applicable cans diameter | 35-70mm ( can be customized) |

6 | Applicable cans height | 70-300mm ( can be customized) |

7 | Applicable valve | 25.4 (1 inch BOV) |

8 | Propellant | N2, compressed air |

9 | Max gas consumption | 6m3/min |

10 | Power | AC 380V/50HZ |

11 | Air source | 0.6-0.7Mpa |

4.Feature

1) It is easy to increase or decrease the equipment, and can be equipped with automatic weighing machine, water bath testing machine, nozzle fastening machine and outer cap fastening machine.

2) The equipment is controllable, the core parameters such as sealing diameter and sealing depth can be quickly and intelligently adjusted.

3) Filling machine adopts touch screen + PLC program control, servo + precision planetary reducer drive, high degree of automation.

4) The equipment is equipped with full can shutdown, blocking can shutdown, no cans do not seal, no cans do not discharge, the operation is simple, convenient and humanized, is the Bag on valve aerosol products of large-scale production of choice.

5.Detail Image

|

Gas Filling & Crimping Head

Gas Filling, then sealing Equipped with a pressure sensor (precision 0.01MPa) to realize the protection of no-pressure non-sealing, to avoid the waste of package material

|

|

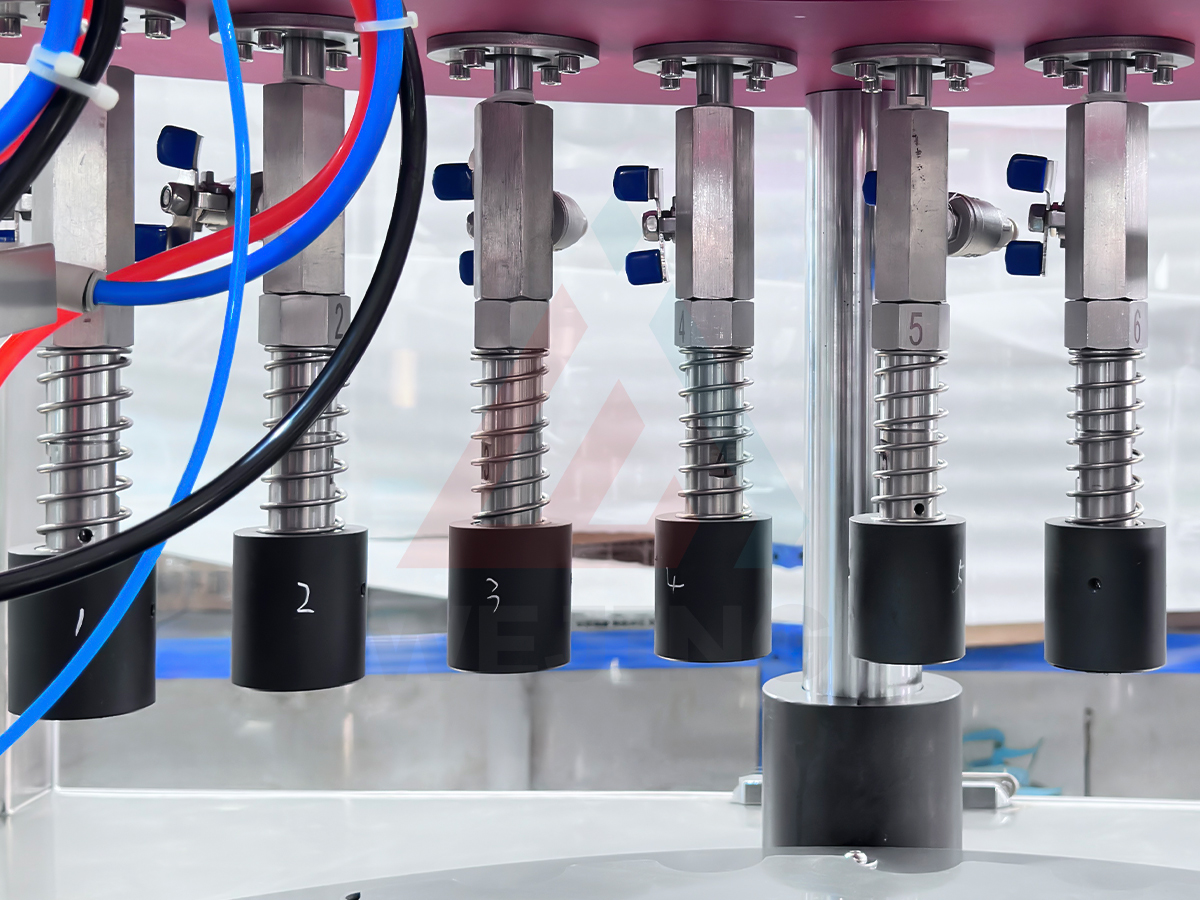

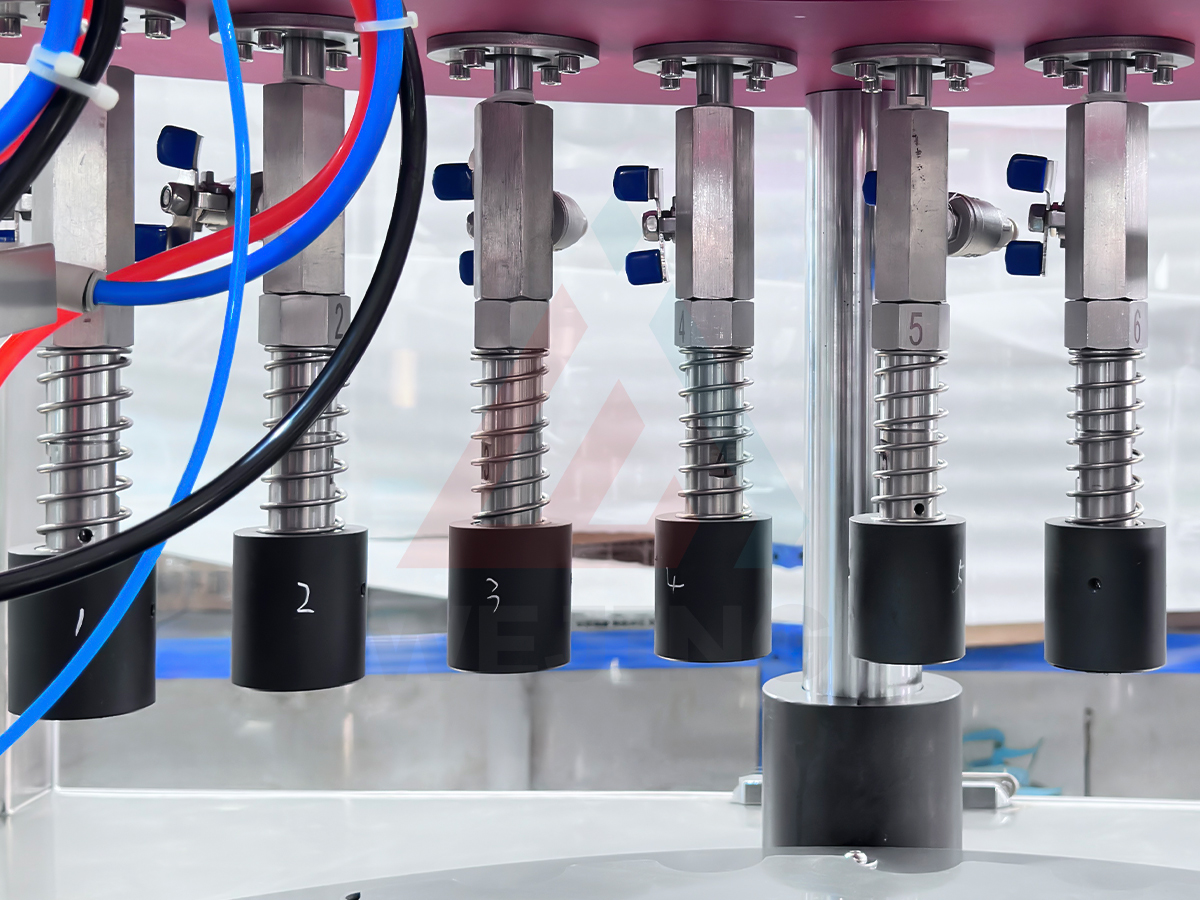

Liquid Filling Head

Guided forced filling head, precision fixed, filling accuracy control

|

|

Pressure Measurement head

Real-time monitoring of the internal pressure of aerosol cans for compliance with standards to ensure product safety

|

|

Cleaning Head The cleaning head can be customized according to customer needs. The main purpose is to clean colored and easily solidified materials. The cleaning medium is the volatilized gas of industrial alcohol and pressurized to clean the remaining material in the valve core to prevent the valve core from clogging. |

|

PLC control

Multi-language interface Touch screen interface, intuitive and easy to understand, real-time monitoring of the production process, with a three-color alarm light to indicate faults |

|

Dosing Cylinder

Be linked with the filling head to ensure the liquid dosing precision through the piston movement and pressure sensor, and the guided forced filling head reduces the residue. |

|

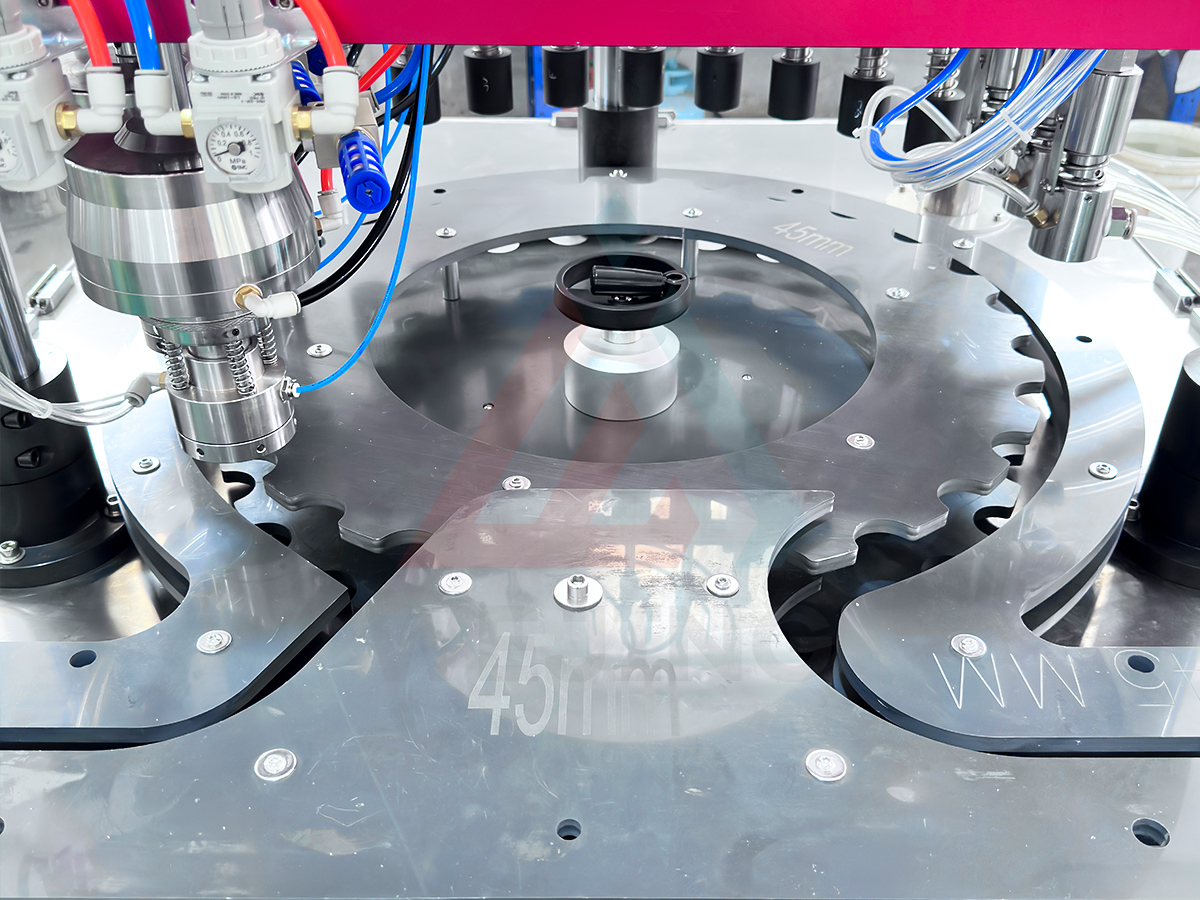

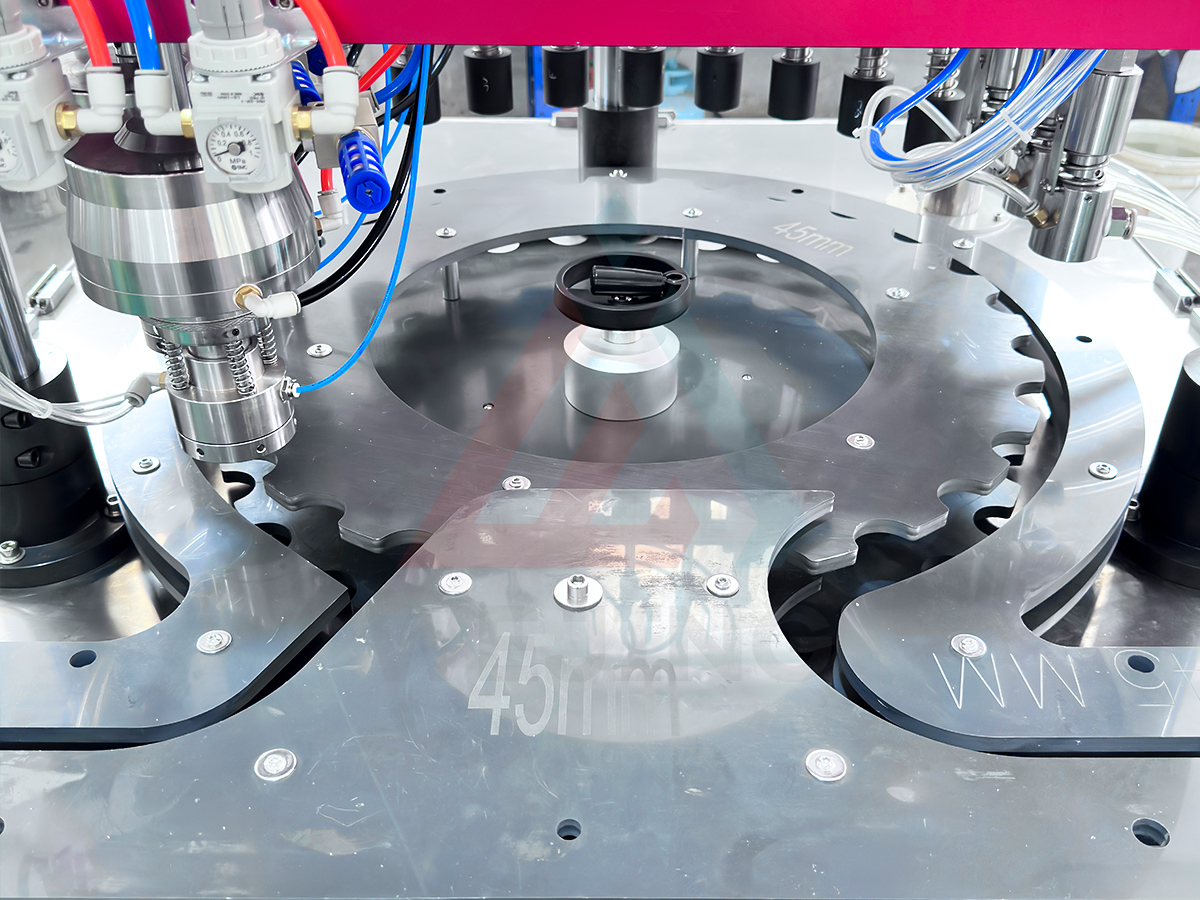

Turntable

Turntable conveyor system, aerosol cans move steadily in a circular motion without wobbling |

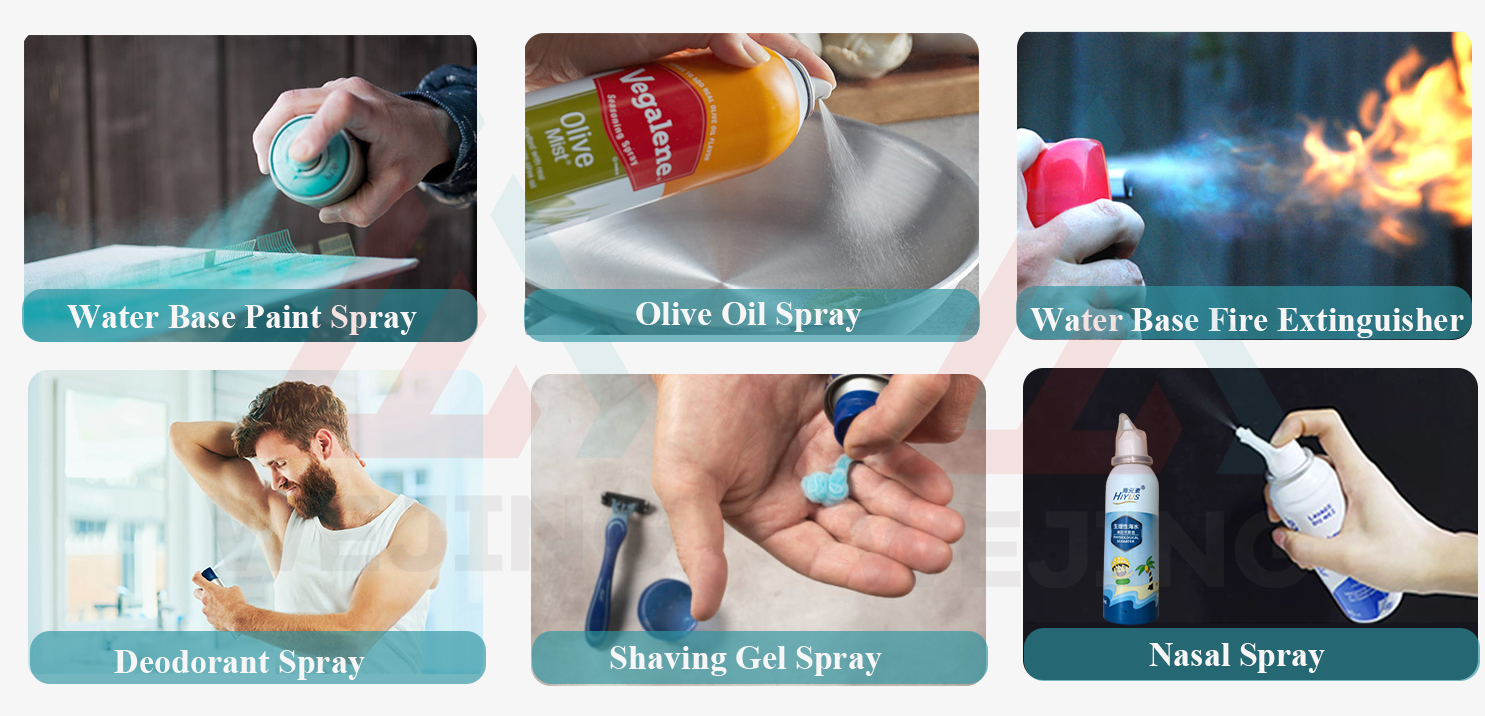

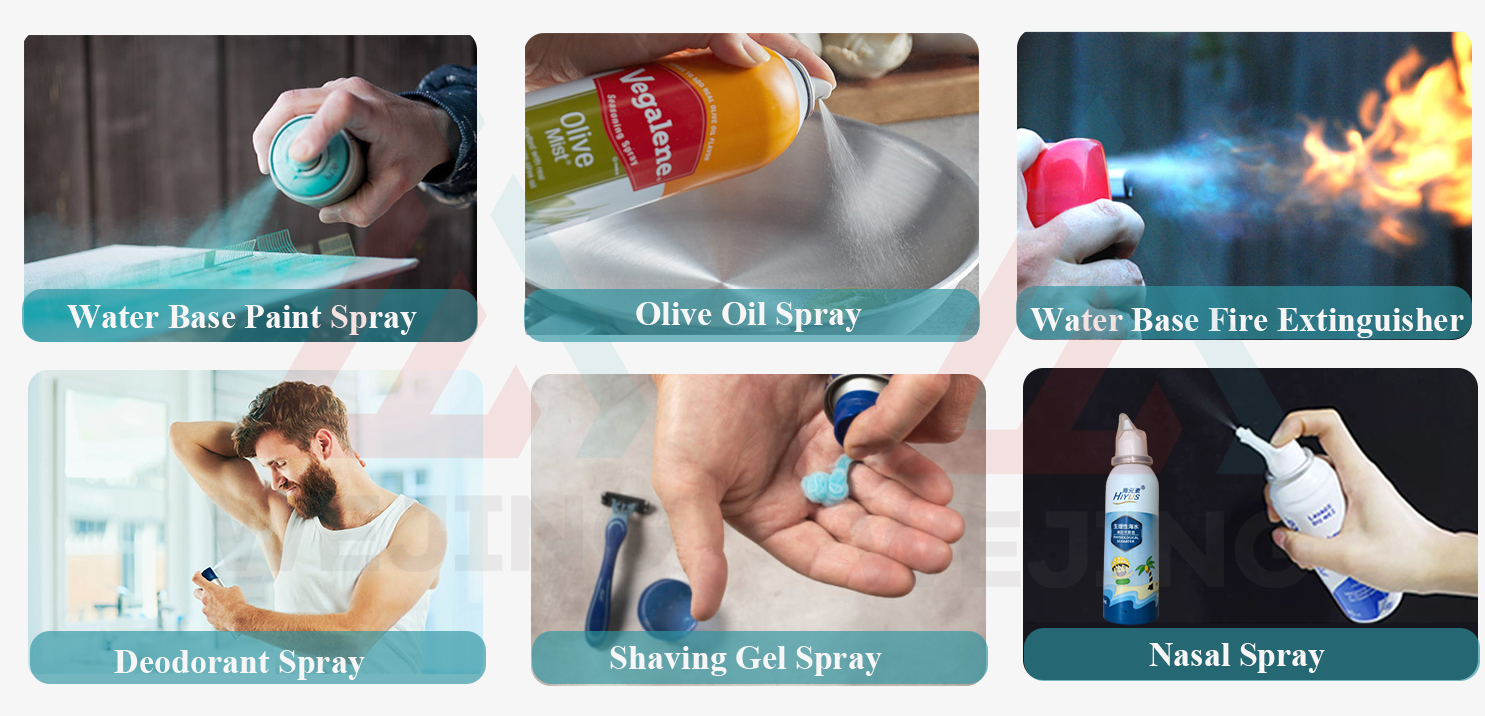

6. Application

The fully automatic BOV Aerosol filling line is fit for filling water base aerosol product.Such as water base fire extinguishers ,water base paint spray,nasal spray ,deodorant spray,oliveoil spray and shaving gel.

7. FAQ

Q1:What types of products can the WJER-80S fill?

It is specifically designed for water-based aerosol products, including water-based fire extinguishers, water-based paint sprays, nasal sprays, deodorant sprays, olive oil sprays, and shaving gels. It is not recommended for oil-based or highly viscous aerosols unless customized.

Q2: Can the machine adapt to different can sizes?

Yes. The standard model fits cans with 35-70mm diameter and 70-300mm height; both diameter and height can be customized according to your specific can specifications (e.g., smaller 30mm diameter or taller 350mm height cans).

Q3: How does the machine ensure filling accuracy?

Liquid filling: Uses a guided forced filling head linked to a dosing cylinder (with piston movement + pressure sensor) to control accuracy within ±1%, reducing residue.

Gas filling: Equipped with a precision pressure sensor (0.01MPa accuracy) to monitor propellant (N₂/compressed air) intake, ensuring accuracy ≤±1%.

Q4:What safety protections does the machine have?

It has multiple safety and anti-waste features:

"No-can no-seal": If no aerosol can is detected, the machine skips sealing and filling to avoid material waste.

"Full-can/shorted-can shutdown": Stops operation if cans are overfilled or blocked to prevent jams.

Pressure monitoring: Real-time checks of can internal pressure to ensure compliance with safety standards.

Q5:Can I expand the machine with other equipment?

Absolutely. The WJER-80S is modular and can be paired with:

Automatic weighing machines (for weight verification),

Aerosol water bath leak detectors (for leak testing),

Automatic nozzle fastening machines,

Automatic outer cap fastening machines,

Online coding machines (for date/batch marking).

Q6:Is the machine easy to operate?

Yes. It uses a touchscreen + PLC program control with a multi-language interface (supports English, Chinese, etc.). Key parameters (sealing diameter, filling volume) can be adjusted quickly, and a three-color alarm light indicates faults (e.g., no air pressure, can blockage) for easy troubleshooting.