| Product Description

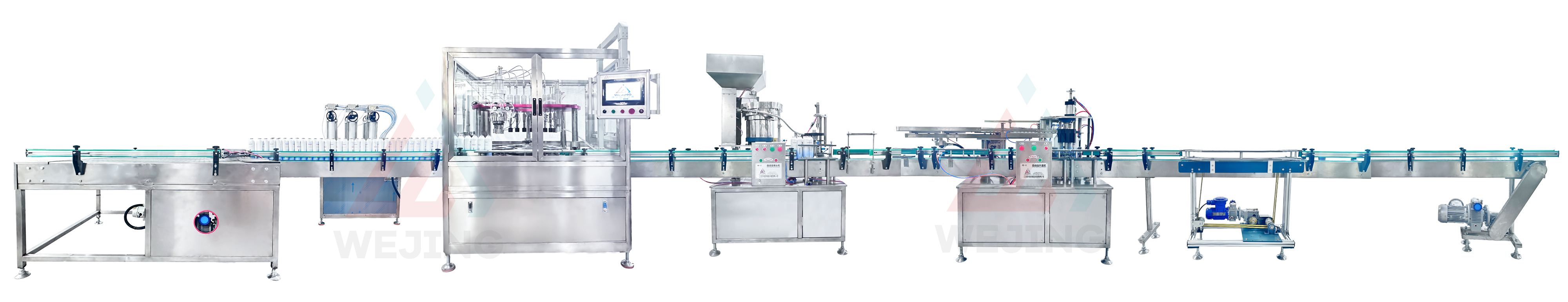

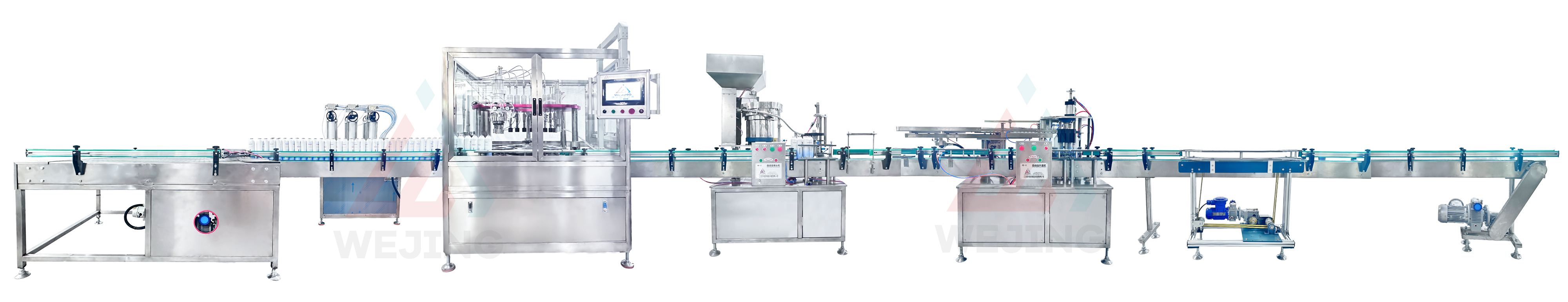

This BOV aerosol filling line consists of a can tending machine, a double-head filling and sealing machine, a liquid filling machine, an automatic weighing machine, an automatic nozzle presser, an automatic cap presser, an automatic coding belt and a packing table. The production speed can be up to 45-60 bottles per minute, which can meet the demand of different scale of production with high efficiency and help enterprises to save time and cost. Its filling capacity is flexible, ranging from 30 - 1200ml. Advanced automation technology ensures high precision and stability. Easy to operate and low maintenance, it is the ideal choice for liquid filling in many industries.

| Parameters

| 1 | Filling capacity (cans/min) | 45-60cans/min |

| 2 | Liquid filling volume (ml) | 10-300ml/head |

| 3 | Gas filling accuracy | ≤±1% |

| 4 | Liquid filling accuracy | ≤±1% |

| 5 | Applicable cans diameter (mm) | 35-70 ( can be customized) |

| 6 | Applicable cans height (mm) | 70-300 ( can be customized) |

| 7 | Applicable valve (mm) | 25.4 (1 inch) |

| 8 | Propellant | N2, compressed air |

| 9 | Max gas consumption (m3/min) | 6m3/min |

| 10 | Power (KW) | AC 380V/50HZ |

| 11 | Air source | 0.6-0.7Mpa |

| Detail Image

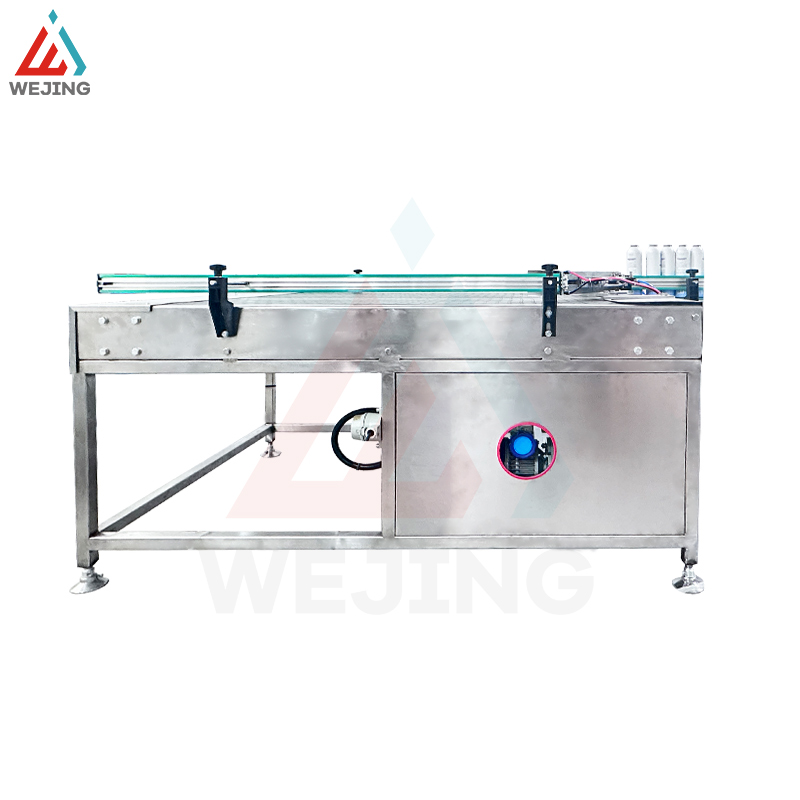

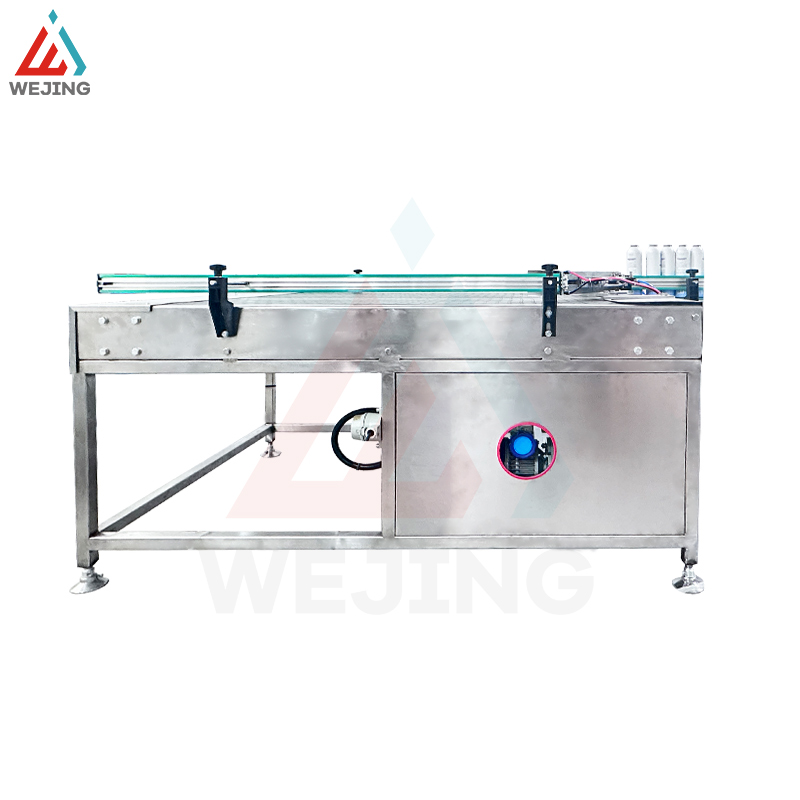

Auto Can Feeding Machine

Keep the cans feeding properly and orderly on the conveyor belt.

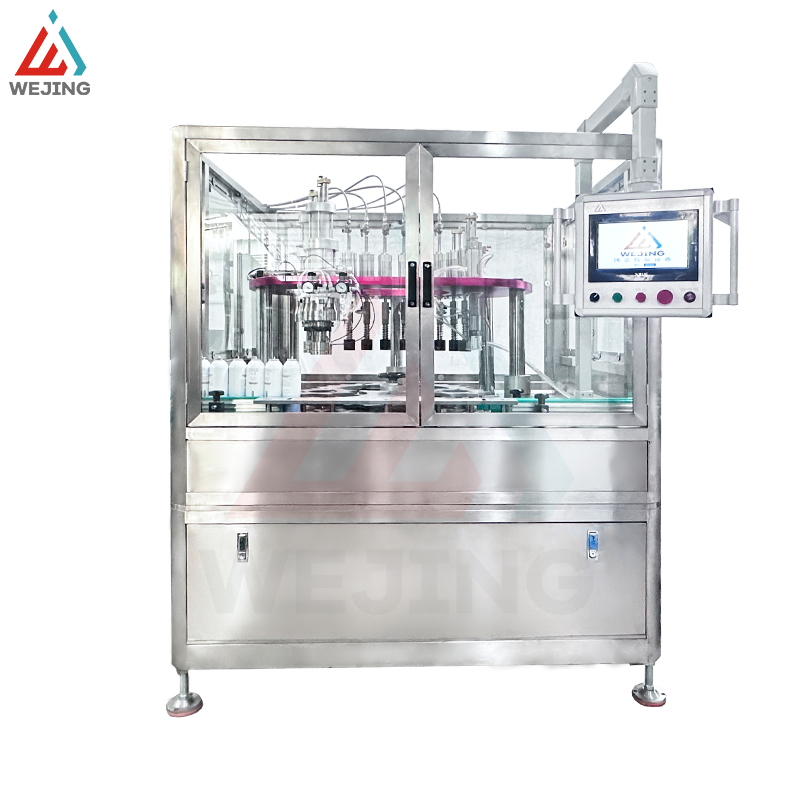

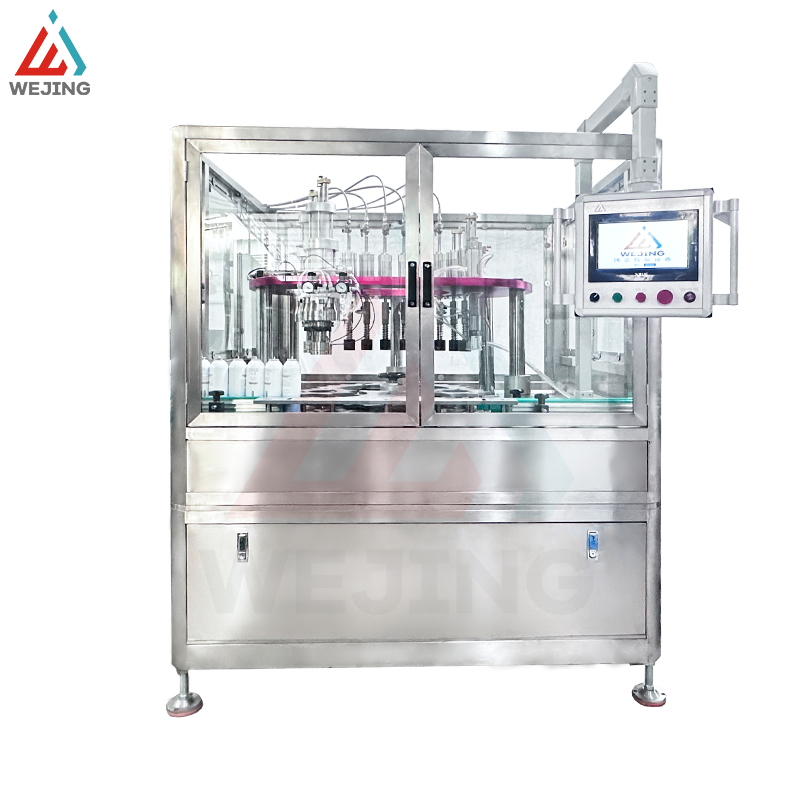

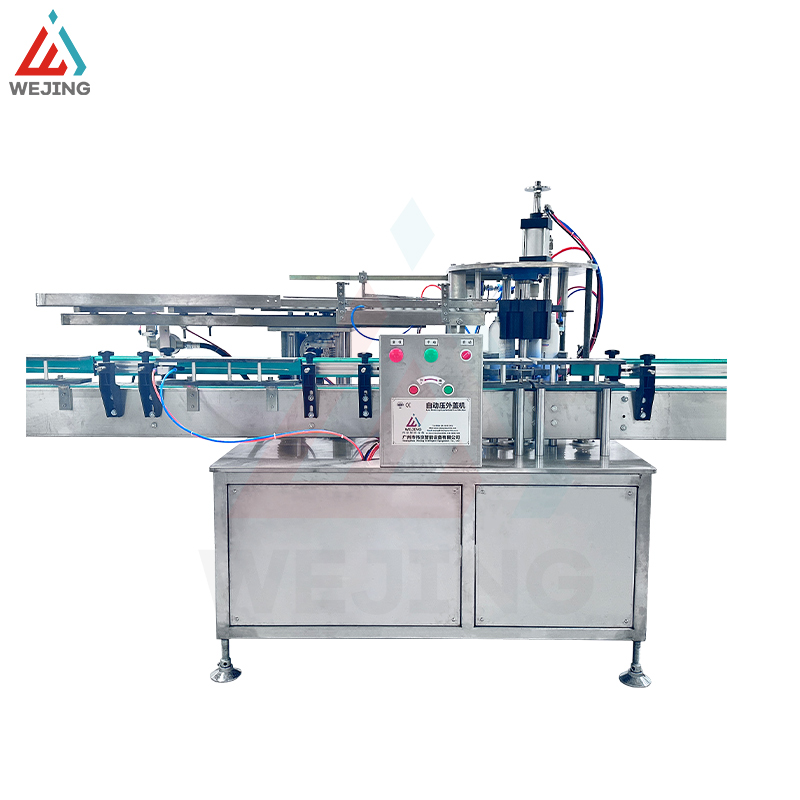

BOV Aerosol Filling & Sealing Machine

2Gas and crimping heads

6 Liquid filling heads

2 Pressure detector heads

2 Cleaning heads

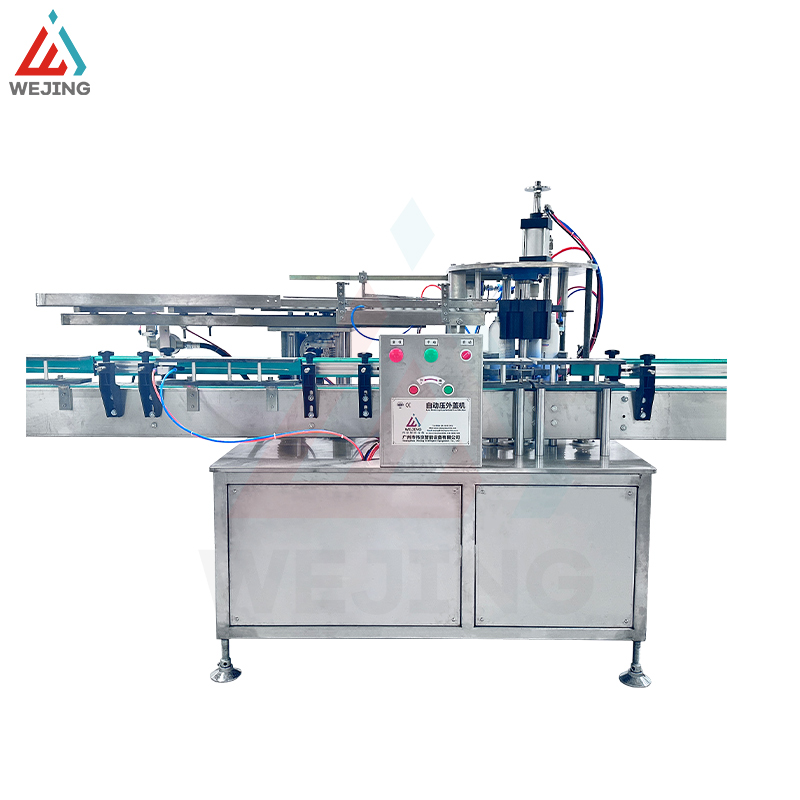

Auto Actuator Fixed Machine

Be used for the installation of spray actuators of aerosol products..

Plastic Cap Inserted and Fixed Machine

Be used for the outer plastic cap packaging of aerosol products,

| Advantage

1. High precision: Fills aerosol spray cans accurately, minimizing product waste and ensuring consistent fill levels for each can.

2. Efficient operation: Can handle a large number of cans in a short time, increasing production output significantly.

3. Stable performance: Operates smoothly with advanced technology, reducing the risk of breakdowns and malfunctions.

4. Quality filling: Ensures the bag - on - valve system is filled properly, maintaining product integrity and quality.

5. Meets industry standards: Designed to fulfill the specific requirements of the aerosol spray can filling process in the industry.

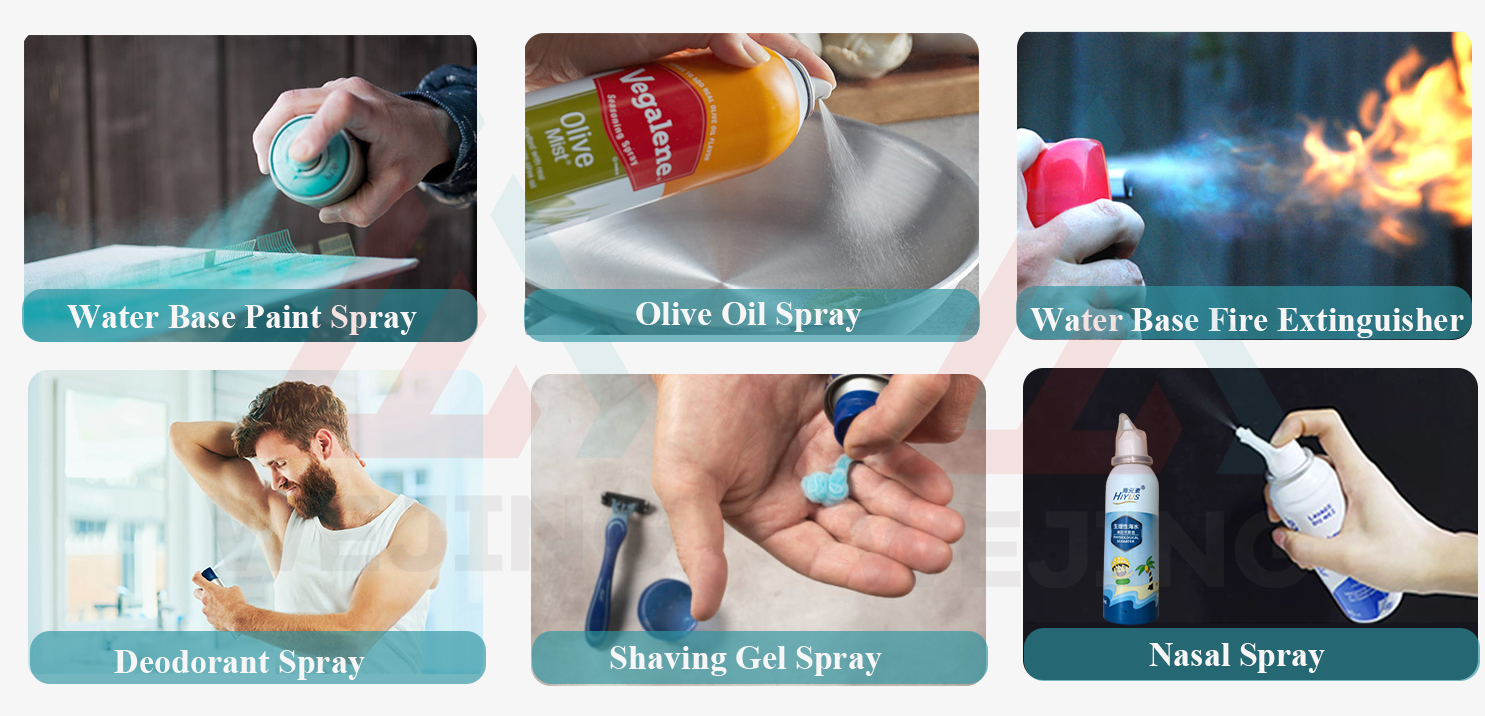

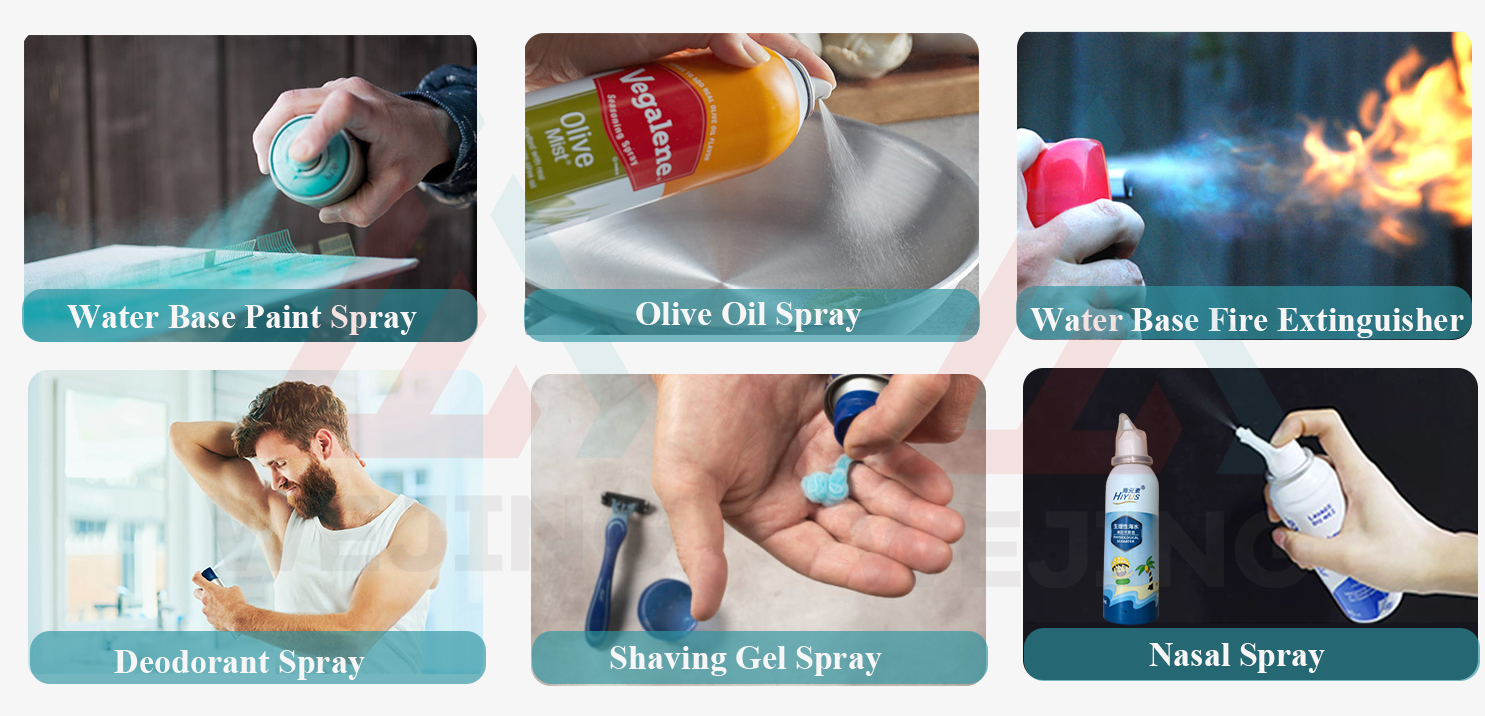

| Application

1.Nasal Spray

2.Olive Oil Spray

3.Deodorant Spray

4.Shaving Gel Spray

5.Water Base Paint Spray

6.Water Base Fire Extinguisher

| Packaging

| Company Profile

Guangzhou Wejing Intelligent Equipment Co., Ltd. is a high-tech enterprise specializing in the development and manufacture of automation machinery and equipment, located in No. 32, Fuyuan Road, Xinya Street, Huadu District, Guangzhou City, China, which is the most comprehensive manufacturer of filling machine specifications at present.

Since its inception, the company has been committed to providing customers around the world with efficient, intelligent and reliable filling and packaging solutions, covering a wide range of products, such as aerosol filling machines, mask machines and other areas. Our self-developed aerosol filling machine adopts advanced automation technology and is characterized by high precision, high efficiency and low loss, which can meet the filling needs of aerosol products of different specifications. The equipment is easy to operate and has strong stability. The company's internal ISO quality management system is strictly implemented, from raw materials to finished products, each link is strictly controlled. Our products are exported to Southeast Asia, America, Africa and other countries and regions, and we have established a perfect after-sales service system to provide customers with timely and professional technical support.

| FAQ

1. What types of products can it fill?

It can fill various aerosol products like nasal cleansers, edible oil sprays, normal saline, and water - based fire extinguishing agents.

2. Is it easy to operate?

Yes. It has a user - friendly interface, making it simple for operators to control and adjust the filling process.

3. How accurate is the filling volume?

It has high precision. Advanced technology enables it to fill with an accuracy that meets the strict requirements of different products.

4. Can it handle different can sizes?

Yes. It's designed to be adjustable to accommodate various aerosol spray can sizes commonly used in the industry.

5. How stable is its performance?

It's very stable. With reliable components and technology, it can operate continuously for long periods with minimal breakdowns.