Product Advantage

1. Boosted Productivity: Our conveyor belt designed for inkjet printing expedites the aerosol filling procedure, trimming production times and augmenting output rates, thereby enhancing the general effectiveness of operations.

2. Accurate Printing Precision: By guaranteeing uniform and meticulous inkjet application on each aerosol container, our conveyor ensures crystal-clear labeling that bolsters product recognition and facilitates effective tracing.

3. Mobile and Adaptable: Engineered with portability in mind, our conveyor belt can effortlessly be relocated and configured to accommodate a range of manufacturing configurations, providing the agility needed in versatile industrial settings.

4. Space-Efficient Design: Thanks to its compact footprint, our conveyor effortlessly integrates within current production layouts, optimizing spatial usage and reducing interference to a minimum.

5. Consistent Dependable Operation: Constructed from premium materials and incorporating state-of-the-art technology, our inkjet conveyor belt is synonymous with unwavering reliability and sustained performance, curtailing idle periods and securing enduring productivity.

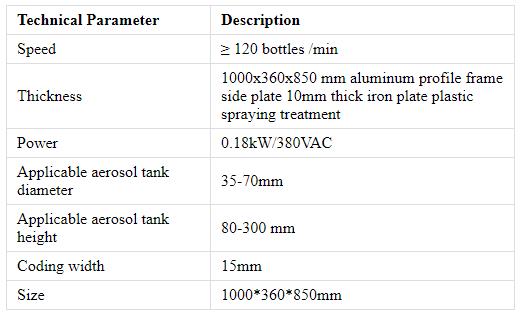

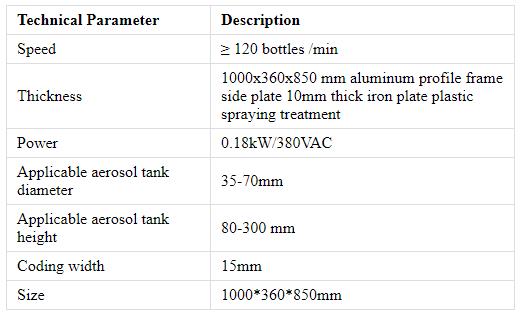

Technical Parameters

Product Uses

1. Precise Identification & Tracing: Tailored for exactness, our inkjet conveyor belt is instrumental in applying pinpoint inkjet prints vital for distinguishing labels and facilitating batch tracking on aerosol containers.

2. Clear Product Info Display: Facilitating the crisp and easily readable reproduction of key details – including product titles, ingredient lists, usage directions, and expiry dates – directly onto aerosol packaging.

3. Custom Brand Enhancement: Offering simplicity in personalization and brand reinforcement, our conveyor empowers businesses to amplify brand visibility through the incorporation of printed logos and striking visuals.

4. Regulatory Conformity: Serving as an anchor in adhering to industry norms, our inkjet conveyor ensures adherence to regulatory standards by implementing a trustworthy, uniform printing practice for meeting legally required disclosures.

5. Assurance of Excellence: Playing a pivotal role in upholding quality standards, it guarantees precise and uniform printing outcomes, mitigating the likelihood of inaccuracies or mislabeling incidents, thereby boosting product excellence and customer contentment.

Product Operate Guide

1. Adhere to the manufacturer's installation instructions and safety protocols to confirm that the inkjet conveyor belt is correctly fastened and synchronized with the aerosol filling machinery.

2. Modify the conveyor’s velocity to synchronize with the production flow demands, assuring a fluid and uninterrupted progression of aerosol containers for optimal inkjet application.

3. Configure the inkjet printer's settings according to the specified print criteria, encompassing font dimensions, content composition, and placement, to attain distinct and easily readable prints on each aerosol bottle.

4. Arrange the aerosol bottles onto the conveyor, taking care that they are evenly spaced and correctly oriented to facilitate uniform and productive printing runs.

5. Maintain a vigilant watch over the inkjet printing operation, periodically examining the clarity and alignment of the imprinted data, and undertake any essential modifications to refine and enhance the printing outcome.

FAQ

Q: Is the conveyor belt adaptable to accommodate aerosol bottles of varying dimensions?

A: Absolutely, our conveyor belt boasts adjustability features, enabling it to cater to a wide array of aerosol bottle sizes, thereby catering to diverse product specifications flexibly.

Q: Does the inkjet-printed text on the aerosol bottles withstand wear and remain smudge-proof?

A: Indeed, our inkjet printing methodology guarantees long-lasting and smear-resistant impressions on the aerosol bottles, preserving the legibility and reliability of all labeled information.

Q: Can this conveyor belt work in conjunction with pre-existing aerosol filling equipment?

A: Certainly, our inkjet conveyor belt has been engineered for straightforward integration with the majority of aerosol filling systems, promoting a smooth operation and boosting production efficacy.

Q: Is periodic maintenance a necessity for the conveyor belt?

A: Yes, routine maintenance is advised to uphold peak performance levels. Accompanying our product is a comprehensive maintenance manual outlining the recommended maintenance procedures.

Q: Could the inkjet conveyor belt find application in packaging tasks besides those involving aerosol bottles?

A: Although tailored primarily for aerosol bottles, our conveyor belt, with appropriate modifications, can indeed be utilized for additional packaging endeavors, such as marking on cans or petite receptacles.