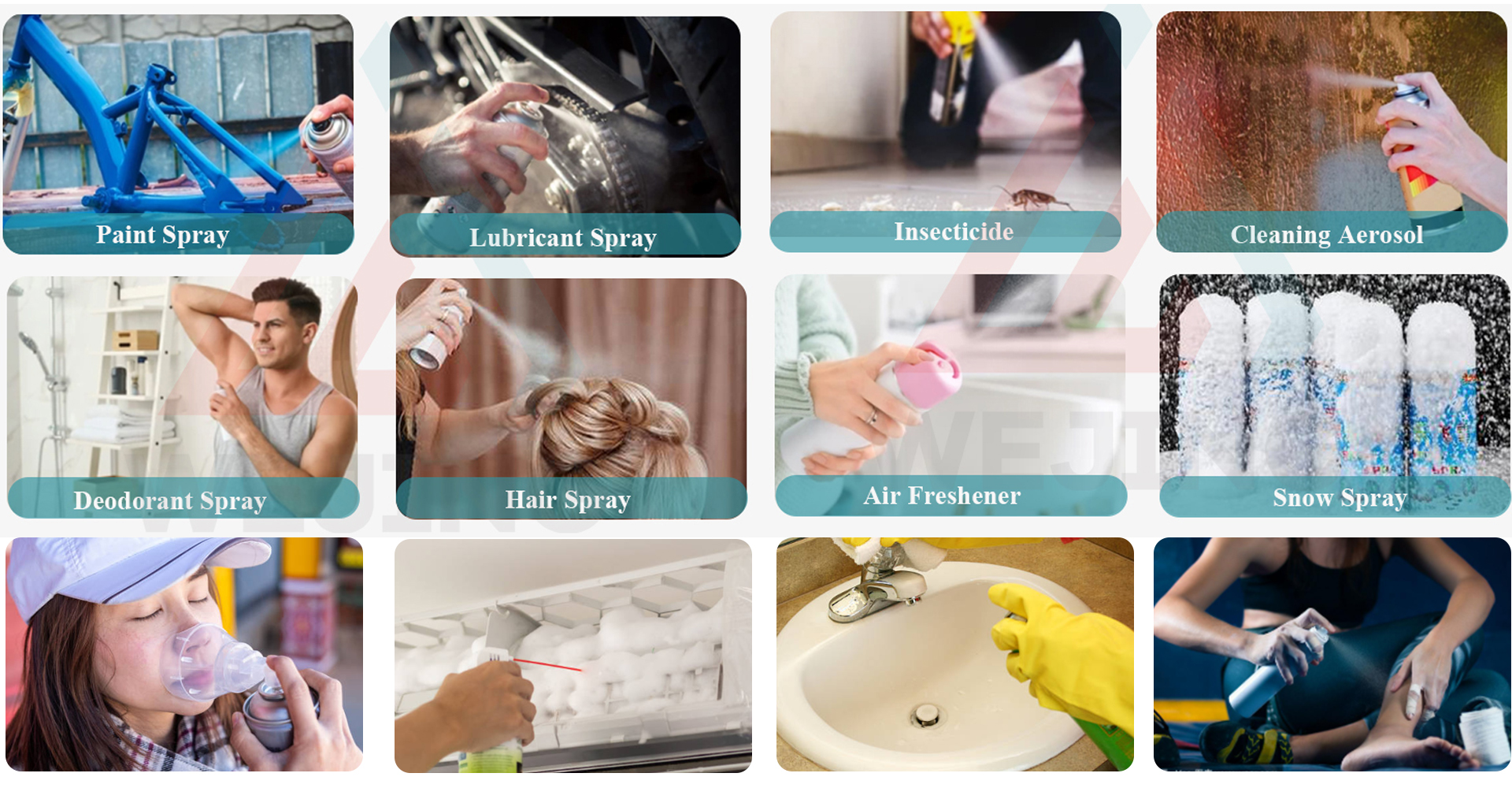

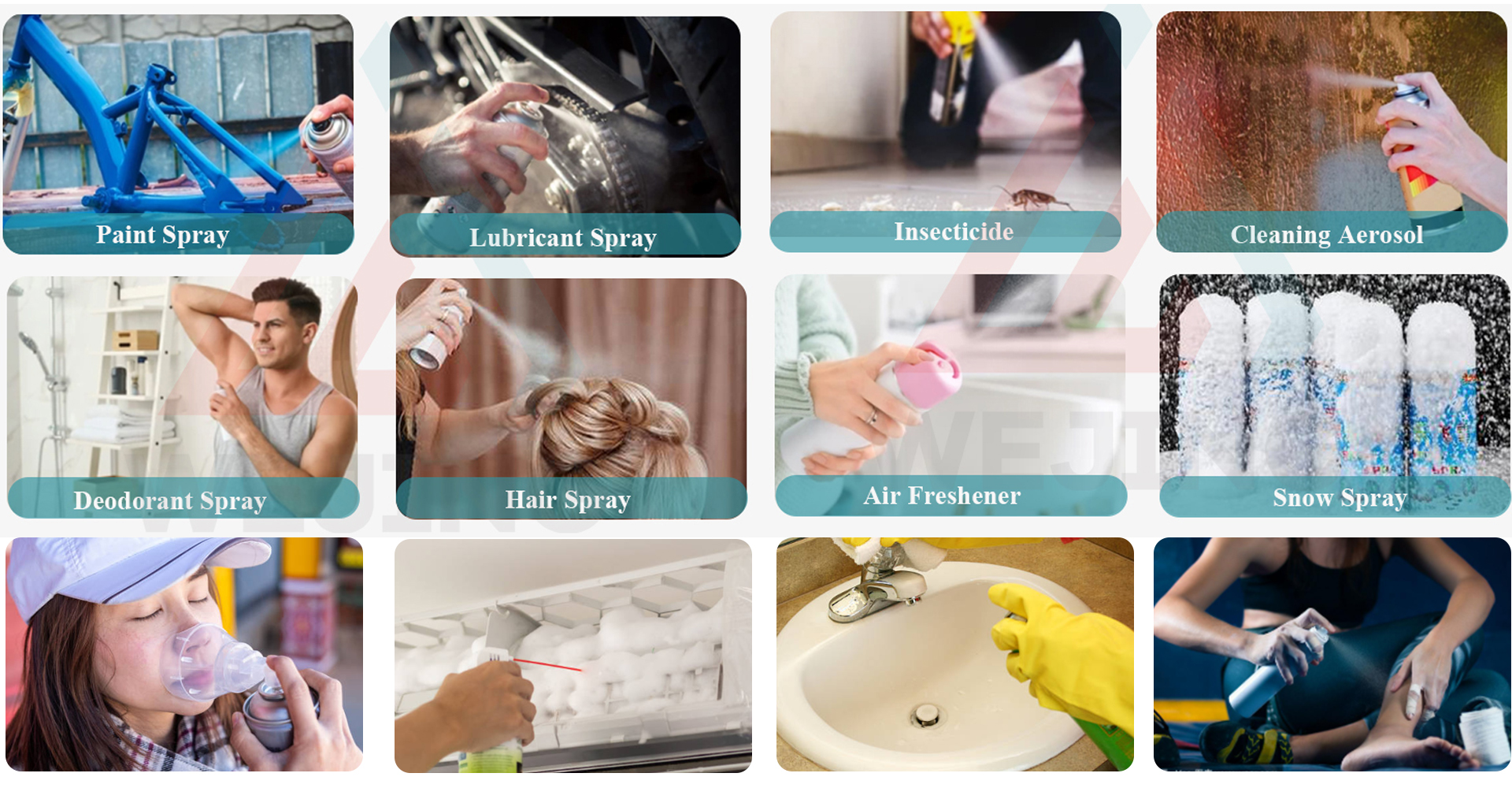

Introducing our Aerosol Can Water Bath Leak Tester, to ensure aerosol product performance and reliability.

This Water bath testing machine is designed to meet the highest standards in can leak testing, providing a seamless and efficient solution for your industrial needs. Trust in our advanced technology to deliver accurate results and enhance your production process. Elevate your quality control measures with our Aerosol Can Water Bath Leak Tester, the ultimate choice for precision and safety.

|

Product Description

The water bath testing machine is the best choice for testing gas leakage in gas-filled products.

1. The automatic water bath leak detector is used to test various aerosol products and is not limited by the filling material.

2. The device (CE certified) uses an explosion-proof motor and is equipped with an automatic overload circuit breaker to ensure safe operation.

3. The entire process includes electric heating, temperature control, automatic clamping, testing, drying, and transportation.4.When the can enters, the water bath testing machine's clamping device secures the can, which is then immersed in hot water at a temperature of 45 to 52 degrees Celsius for approximately 3 to 5 minutes to detect any gas leaks. The can then enters the blowing system, where hot air dries the can and transports it to the conveyor belt.

| 1 | Temperature accuracy | ± 1 ℃ |

| 2 | Water heating power | 45KW |

| 3 | Drying power | 3kw |

| 4 | Water tank capacity | 1.1m³ |

| 5 | Max air consumption | 3 m3 /min/0.6MPa |

| 6 | Capacity | 0-70cans/min |

| 7 | Main Drive Power | 2kw |

| 8 | Soaking time | 3-5min |

| 9 | Suitable can diameter | 35-73mm |

| 10 | Suitable can height | 90-330mm |

| 11 | Working Plate | SS304 |

|

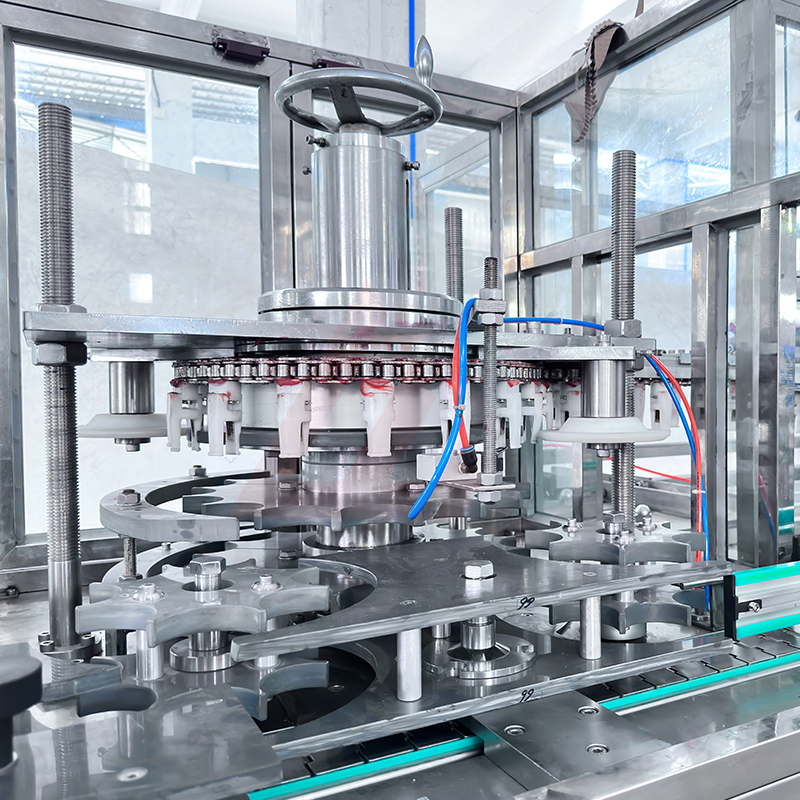

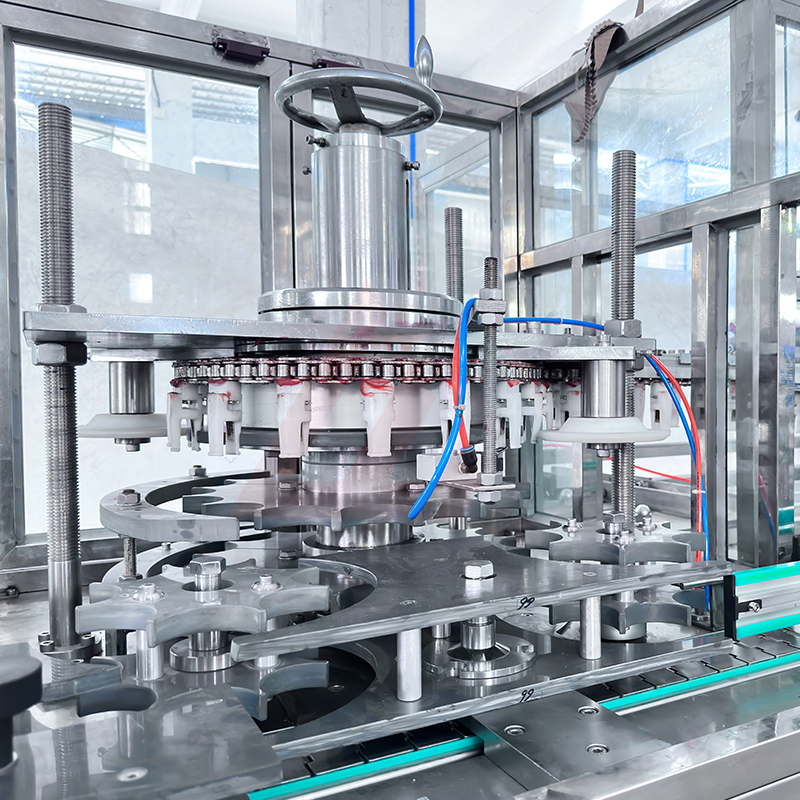

Detailed Image

Mainframe

Automatically clamps the aerosol can product and brings it into the water bath through the mainframe for continuous water bath testing work.

Water testing Tank

Driven by the tank body six-channel chain plate products in the water temperature of 45 ℃ ~ 50 ℃ of the tank body soak walking 3-5min, and then leave the water surface for hot air blowing can body drying, and finally into the exit buffer platform.

|

Work Flow

(1)Hanging chain convey aerosol cans

(2)water bath immersion for 3-5 minutes (observe whether there is any leakage)

(3)multi-directional air knife blow-drying

(4)Aerosol can output.

Explosion-proof design

heat-insulated electric heaters and explosion-proof electric appliances ensure safety.

High-efficiency drying

alve cup, can bottom and side wall three-way wind knife to remove residual water.

Linkage production line.

an be integrated with filling machine and labeling machine

((1)How to cope with the inspection needs of different tank types?Adaptive pneumatic fixtures (with tool change) are standard, and non-standard customization is supported.

(2) Will the water bath corrode the tank?

50℃ pure water circulation + 304 stainless steel chain plate, in line with industry standards.

(3) Can it be integrated into existing production lines?

Provide free layout design, docking capper/labeler PLC system.

(4)How long is the warranty of Water Bath Leakage Testing Machine

We offer a two-year warranty on.