Product Advantage

1. Utilizing SS316 pneumatic components, it boasts a low failure rate and stable, reliable performance. Customization is also possible as per customer requests.

2. This equipment has a low investment cost yet a high output, with an hourly production of 3600-4200 cans.

3. The machine's advantage lies in its ease of operation, saving manpower and space.

4. Designed in accordance with GMP requirements and made from international SUS316L and SUS304 stainless steel.

5. It employs a bottle-free and roll-free system. In case of unconventional issues (such as counting errors or bottle leakage), the machine will automatically trigger an alarm or cease operation.

Technical Parameters

Technical Parameter | Description |

Filling capacity (cans/min) | 60-70 |

Liquid filling volume (ml) | 10-1200( can be customized) |

Gas filling volume (ml) | 10-1200( can be customized) |

Filling heads | 4 heads |

Filling accuracy | ≤±1% |

Applicable cans diameter (mm) | 35 - 70( can be customized) |

Applicable cans height (mm) | 80 - 300( can be customized) |

Applicable valve | 1 inch |

Working pressure (Mpa) | 0.6 - 0.8 |

Max gas consumption (m3/min) | 5 |

Power (KW) | 7.5 |

| Material | SS304 ( some parts can be SS316) |

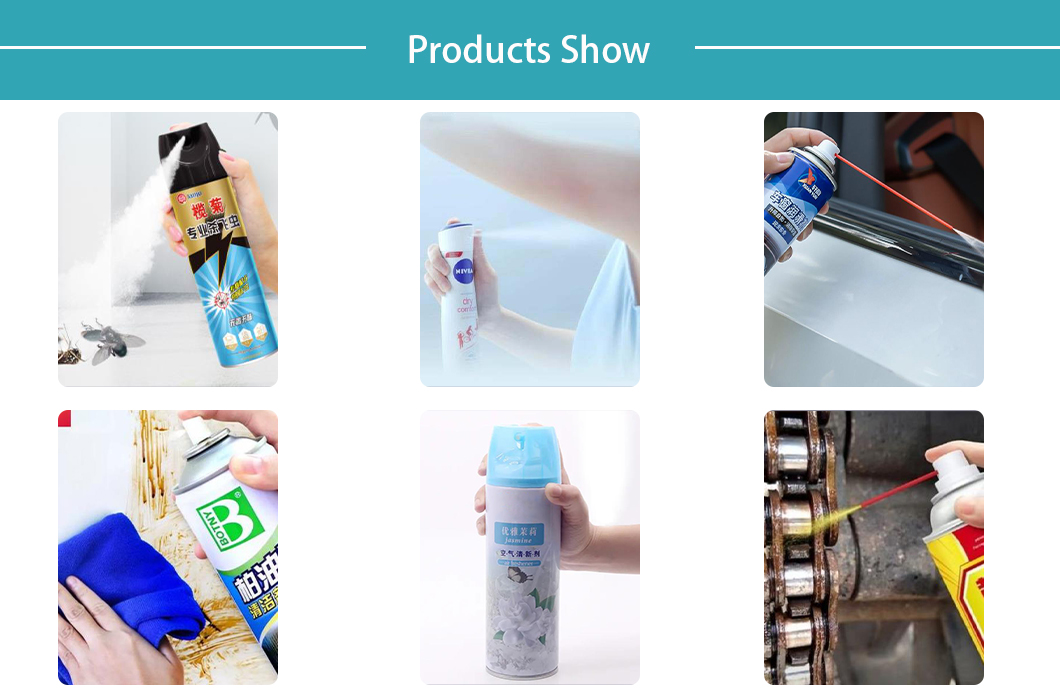

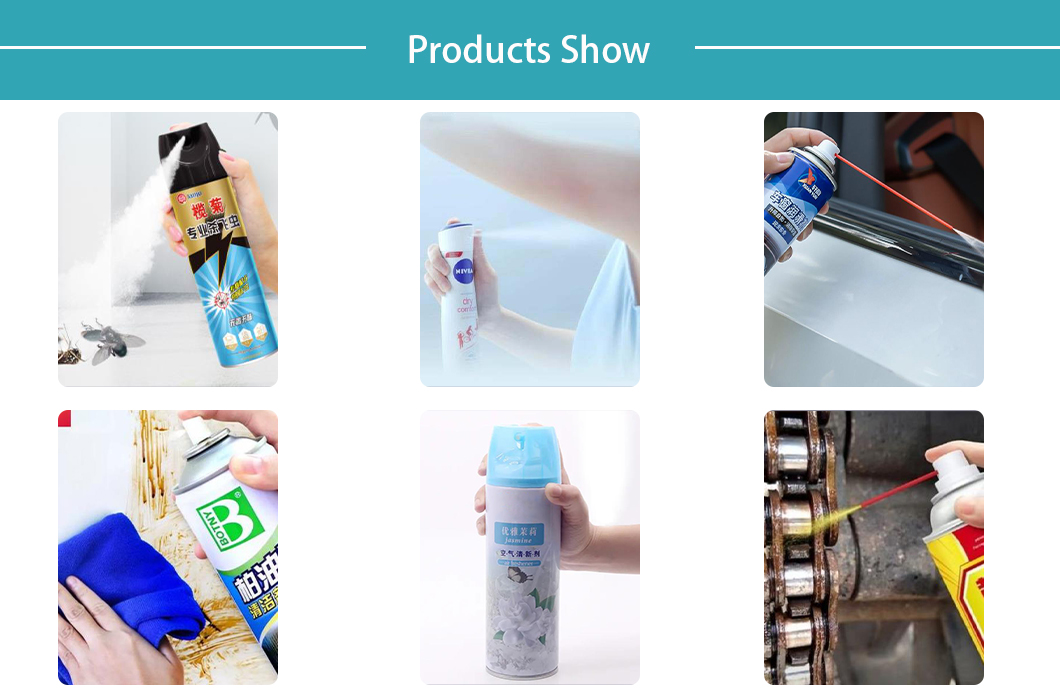

Product Uses

This machine is mainly suitable for snow spray and spray painting products, which need glass bead machine. If your product is not spray painted, you can remove the glass bead machine, which is suitable for various typical aerosol products. Examples include air freshener, deodorant, perfume, furniture spray, insecticide, mosquito control spray, pesticide, leather spray, toilet spray, disinfection spray, hair spray, cosmetics spray, self-defense spray, drug spray, food spray, wound spray, tire repair spray, demoulding spray, rust prevention spray, color paint spray, PU foam and fire extinguisher.

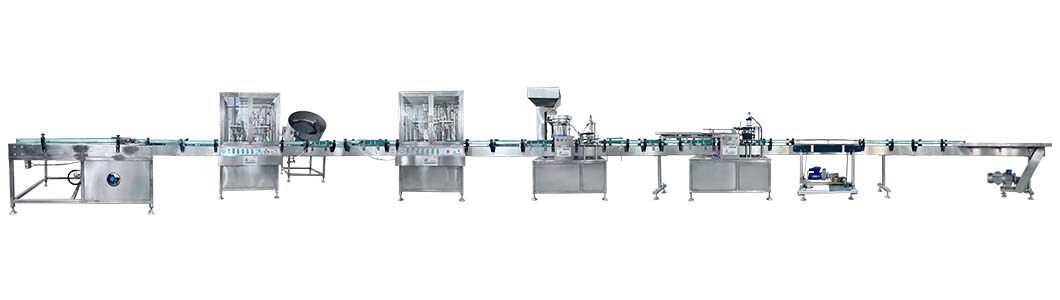

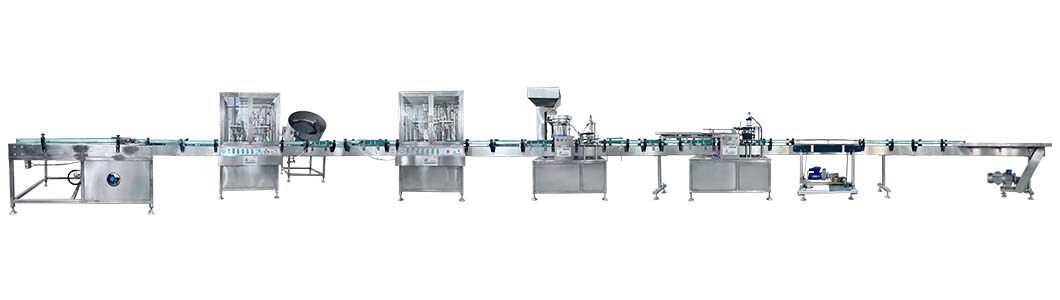

Detailed Images:

Liquid Filling Machine & Valve Insert Machine:

Automatically fill the aerosol material into the aerosol bottle, with a filling volume of 10-300ml per filling head and an accuracy of up to 1%. The operation is simple and saves labor costs.

Automatically fill the valve into the aerosol bottle.Fully pneumatically driven components ensure safe operation. Valve insertion is flexible.

Crimping Machine & Gas Filling Machine:

Pneumatic power is used to drive all parts, ensuring safe operation.

Gas filling heads and filling volume can be customized as needed.

A diverse range of propellants can be used, such as compressed air, LPG, DME, CFC, nitrogen, carbon dioxide, and others.

Auto Actuator Fixed Machine:

This machine is used for installing aerosol product nozzles, with the main features of saving labor, increasing production speed, increasing product stability, and reducing losses. It adopts pneumatic drive.

Semi Auto Capping Machine:

A plastic lid for fixed aerosol products, suitable for packaging aerosol product covers, with fast production speed and stable quality.