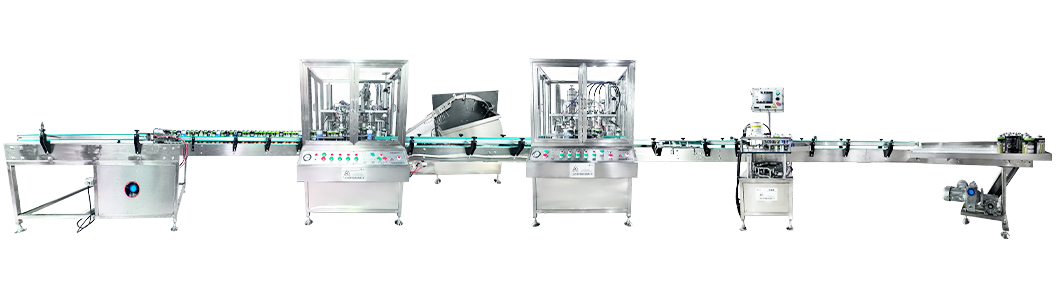

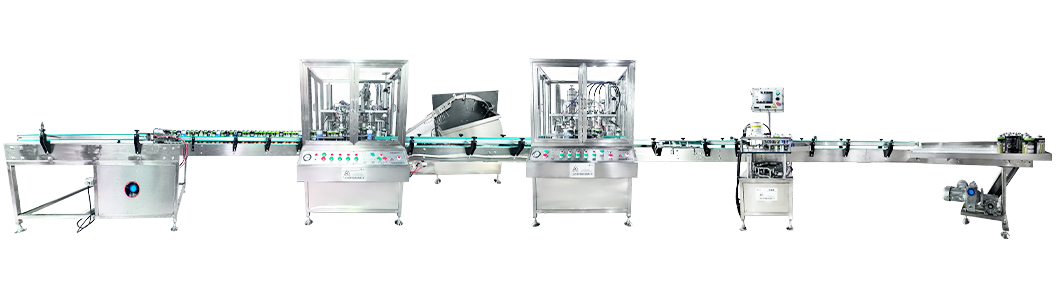

Operation Process:

Aerosol can feeding table --- Automatic conveyor cans input --- Can detector head & Automatic liquid filling & Automatic insert valve & Correcting valve --- Automatic air inflating and crimping --- Weight checking----Worktable

Technical Parameters:

Technical Parameter | Description |

Filling capacity (cans/min) | 60-70 |

Liquid filling volume (ml) | 10-1200( can be customized) |

Gas filling volume (ml) | 10-1200( can be customized) |

Filling heads | 4 heads |

Filling accuracy | ≤±1% |

Applicable cans diameter (mm) | 35 - 70( can be customized) |

Applicable cans height (mm) | 80 - 300( can be customized) |

Applicable valve | 1 inch |

Working pressure (Mpa) | 0.6 - 0.8 |

Max gas consumption (m3/min) | 5 |

Power (KW) | 7.5 |

Dimension (LWH) mm | 22000*3500*2000 |

Material | SS304 ( some parts can be SS316) |

Warranty | 1 year |

Key Selling Points | High speed fully automatic high production |

Maintenance Requirements | Recommended maintenance procedures and schedules |

Certifications and Standards | CE&ISO9001 |

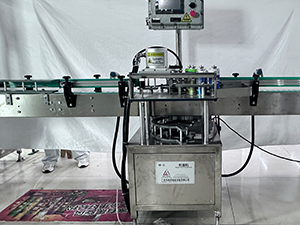

Detailed Images:

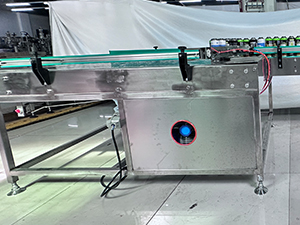

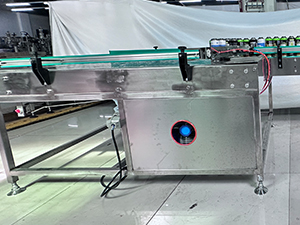

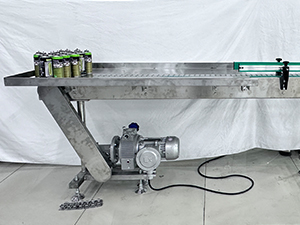

Auto Can Feeding Machine:

Aerosol products production normally needs to run fast from the cans feeder machine. To let the cans move quickly, there are 13 flat-roofed conveyor belts and an explosion-proof motor to change the transporting speed.

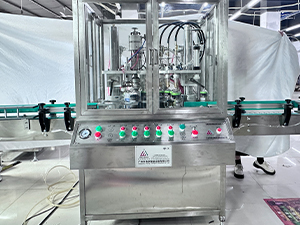

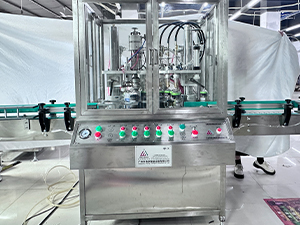

Liquid Filling Machine:

There are 4 liquid filling heads, which can meet the needs of users to fill materials of multiple colors or properties at the same time. Moreover, it is very easy to clean up each filling head. These two features make this automatic liquid filling machine is the best automatic filling equipment.

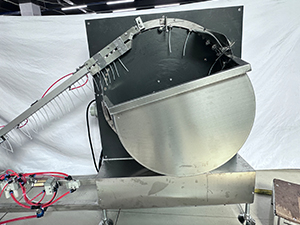

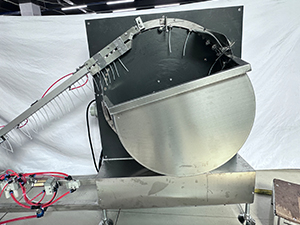

Insert Valve:

This automatic valve insert is divided into 3 parts which include valve sorting turntable, valve blowing part and valve placing part.

Crimping and Gas Filling Machine:

This automatic aerosol filling machine is equipped with 4 gas filling heads on one workbench respectively. Each filling head is controlled by the corresponding filling cylinder, the gas filling volume and filling speed, the smaller gas filling volume the higher filling accuracy. Users can filling 4 different kinds of gas or filling one kind of gas at the same time.

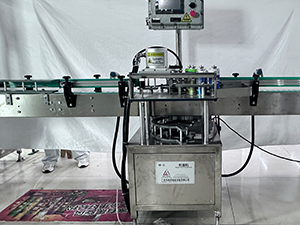

Weight Checking Machine:

This high-speed automatic aerosol weight check machine is designed with a stable and highly sensitive weighing sensor and signal acquisition instrument. It aimed to carry out high-speed operation processing by applying a PLC.

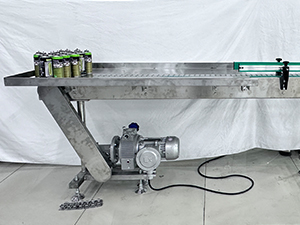

Packing Table:

Suitable for the production of various aerosol products in diverse industries including cosmetics, pharmaceuticals, household care, industrial & institutional care, auto care, etc.

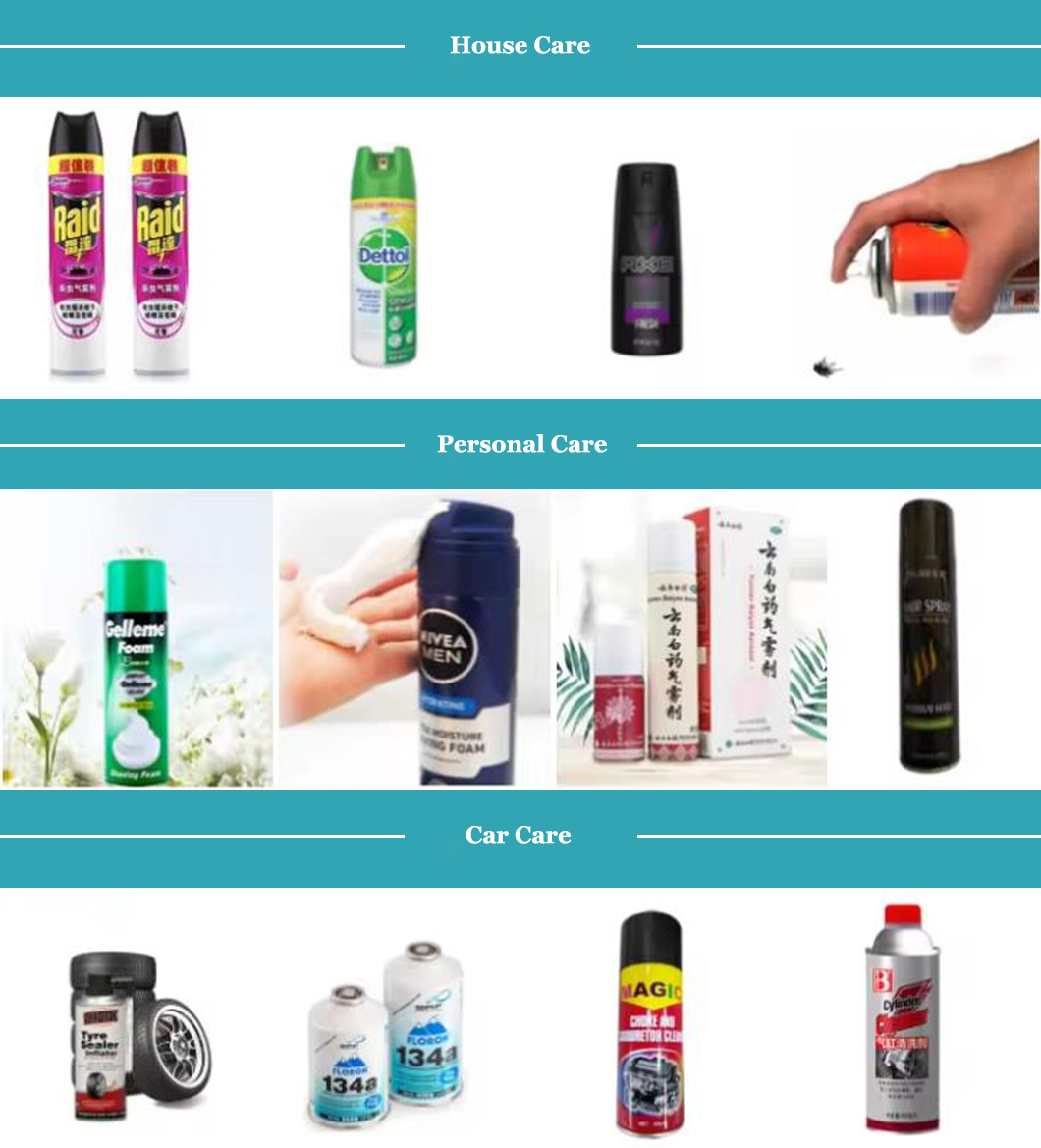

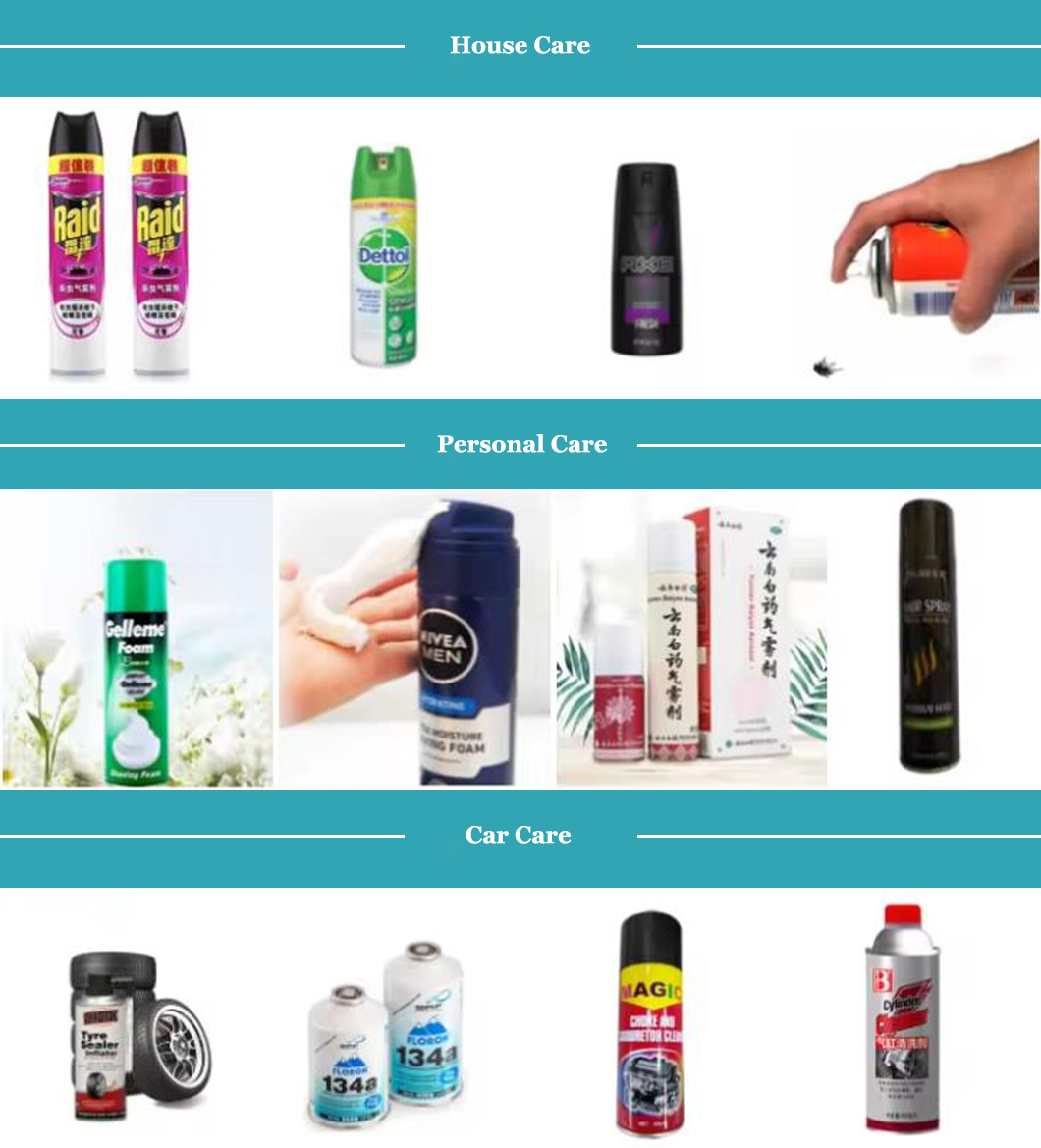

Products Show:

The most common propellant is a liquefied gas. There can be somepropellant, in the form of a gas above the product, present in a standardaerosol. When the valve opens, this gas forces the liquid up into the diptube and out. Liquefied gas and products make up the liquid.

There are uses for aerosol filling equipment in many different industries.

Household Products Aerosol Industry

Personal Care Aerosol industry

Automotive Aerosol Products

Technical Aerosol industry

Food Aerosol industry

FAQ:

Why Aerosol Filling Machines are in High Demand?

There have been many different ways to fill aerosol canisters over the years. The new automated machines make aerosol production a lot easier. Because of new aerosol filing machines, businesses have been able to keep up with the rise in demand for aerosols. As this equipment technology advances, it should help industries meet the growing demand for aerosols.

Automatic Aerosol Filling Machines Benefits?

There are several benefits to using automated aerosol machines. When it comes to filling and packing aerosol products, they can do so quickly. In a short amount of time, this machine can make many aerosol products. Automatic machines don't need as much attention, which means less work is needed to keep them running. This equipment is self-operating and doesn't need to be watched or controlled all the time. As a result, there are fewer workers at the manufacturing plant. When you use an automatic aerosol filling machine, it is more efficient and productive.

Automated aerosol machines are helping companies stay updated:

Automated aerosol filing machines can meet the growing needs of the aerosol business. Spray products are becoming more popular now and in the next few years, as these goods are easy to useand widely used in daily lives. Also, there are many chemical products today, leading to a double risein demand.

Aerosol products are also being used in the industrial field and many other industries. Automatic aerosol filing machines are steadily improving in response to these diferent needs. These machines can work at a very high speed and are available readily as soon as you need one.

Over time, it is expected that aerosol filling machines will continue to be more adaptable and efficient,making them popular and useful in the future.

Our Service:

Pre-sale services:

1. Providing professional technical support.

2. Send the product catalog and instruction manual.

3. If you have any question PLS contact us online or send us email, we promise we will give you a reply at the first time!

4. Personal call or visit are warmly welcome.

Sale of services:

1. We promise honest and fair, it's our pleasure to serve you as your purchasing consultant.

2. We guarantee punctuality, quality and quantities strictly implement the terms of contract.

After-sales service:

1. Where to buy our products for 2 years warranty and life long maintenance.

2. A large stock of components and parts, easily-worn parts.