|

Product Introduction

This production line composed of multiple devices to meet the filling requirements of lubricating aerosols (such as ejpin lubricants, anti-wear grease aerosols, etc.). This solution ensures high-precision and high-efficiency filling and sealing while also taking into account the universality of the equipment - except for the red tube pasting machine which is a special equipment for lubricant aerosols, the rest of the equipment can be adapted to other aerosol products (such as cleaners, rust removers, etc.), achieving flexible configuration and efficient utilization of the production line.

|

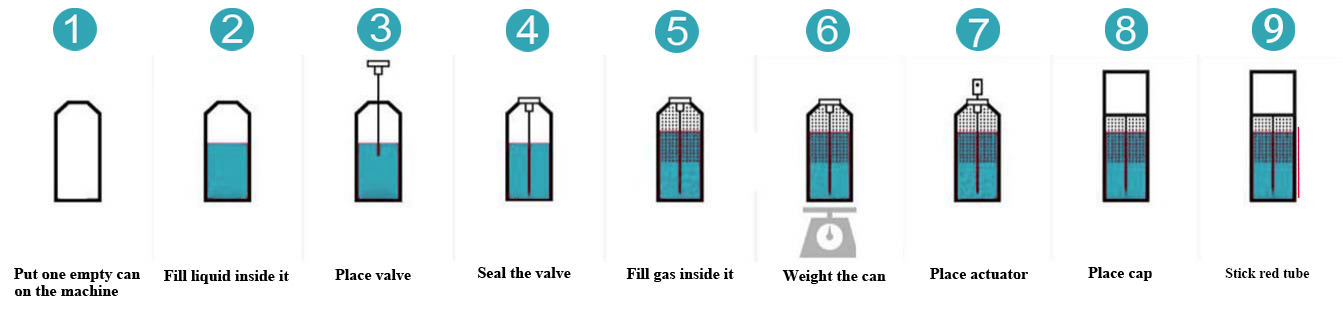

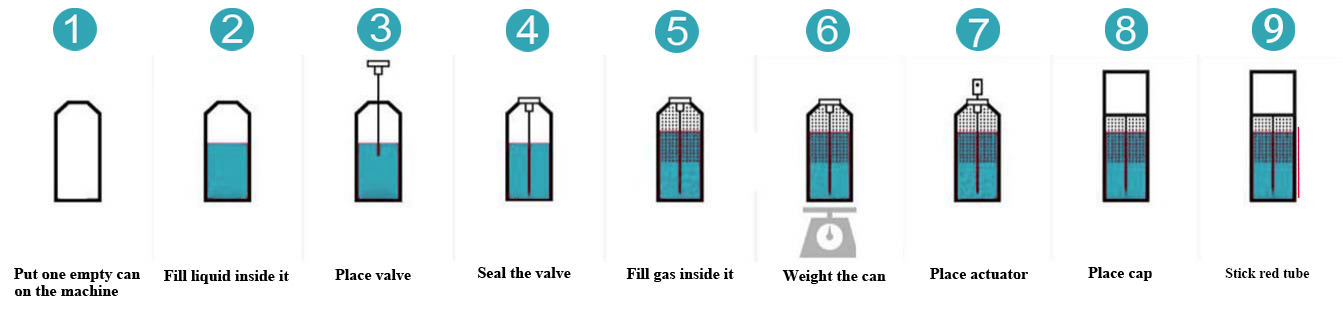

Process Flow

|

Parameter

NO. | Name | Description |

1 | Filling capacity | 60-70cans/min |

2 | Liquid filling volume | 10-1200 ml ( can be customized) |

3 | Gas filling volume | 10-1200ml( can be customized) |

4 | Filling heads | 4 liquid heads & 4 gas filling head |

5 | Filling accuracy | ≤±1% |

6 | Applicable cans diameter | 35 - 70mm( can be customized) |

7 | Applicable cans height (mm) | 80 - 300mm( can be customized) |

8 | Applicable valve | 1 inch |

9 | Working pressure | 0.6 - 0.8Mpa |

10 | Max gas consumption | 5m3/min |

11 | Material | SS304 ( some parts can be SS316) |

|

Feature

1) This machine is composed of a bottle arranging workbench, a fully automatic filling machine, an automatic valve loading machine, an automatic sealing and gas filling machine, an automatic weighing and rejection machine, an automatic nozzle loading machine, an automatic large cap loading machine, and a collection platform.

2) The liquid filling system adopts a piston working principle and is suitable for various viscous liquids. It is all made of 304 stainless steel. It has 4 liquid filling heads and can freely switch between point operation and automatic modes.

3) The sealing head adopts a guiding sealing method. If the sealing quality is not high, the machine will automatically stop. The inflation head adopts a guiding inflation method, which is accurate, efficient and consumes very little air.

4) The conveying system can be designed in a U-shaped rotary structure to save space.

5) This machine features high production efficiency, safety and reliability, simple operation and convenient maintenance.

|

Machine Detail

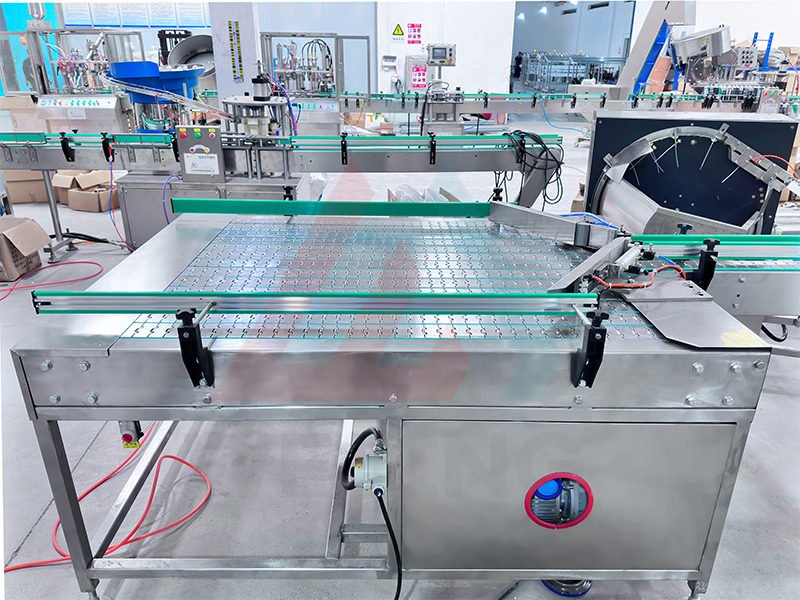

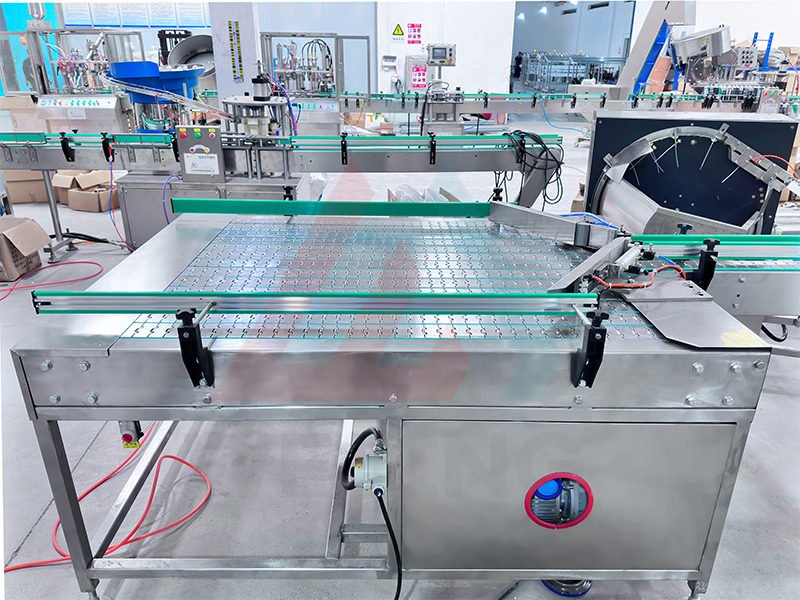

1.Empty cans feeder

Continuously transferring cans from the arranger to other equipment for automatic conveying.

The conveying speed is adjusted by adjusting the speed difference (e.g. speed differential) of the motors to meet different production requirements.

2.Filling and Valve Inserted Machine

1.Can detecter head. No can,No working

2.4 liquid filling heads

3. Valve inserted

4. Valve centralized

Speed:60-70 cans/min

Filling volume:10-1200 ml ( can be customized)

3.Gas filling machine

1.Valve centralized

2. Crimping head

3. 4 Gas filling heads

4. Each part can be controlled independently

Speed:60-70 cans/min

Filling volume:10-1200 ml ( can be customized)

4. weight checking machine

Check the weight of the filled cassette cans, screen out the overweight or underweight defective products, and ensure that the dosage of each can meets the standard.

The inspection speed is synchronized with the filling line, and comes with automatic rejecting device for non-conforming products, without manual intervention.

5.Auto Actuator Pressing Machine

Auto actuator presser machine is used for the installation of spray nozzle of aerosol products.

6.Aerosol can cap fitting machine

Automatically press the cap on the tested tanks, and accurately fasten the protective cap on the outside of the valve to prevent the valve from being damaged or mishandled during transportation.

The strength of the gland can be adjusted without skewing or falling off.

|

Application

This machine is a large-scale assembly line configuration, suitable for mass production enterprises, and meets the standardized factory construction requirements of Aerosol Anti Rust and Lubricant Spray producers

|

Product Description

Lubricant aerosol filling line

Wooden case protection

Transpotation

|

Product Description

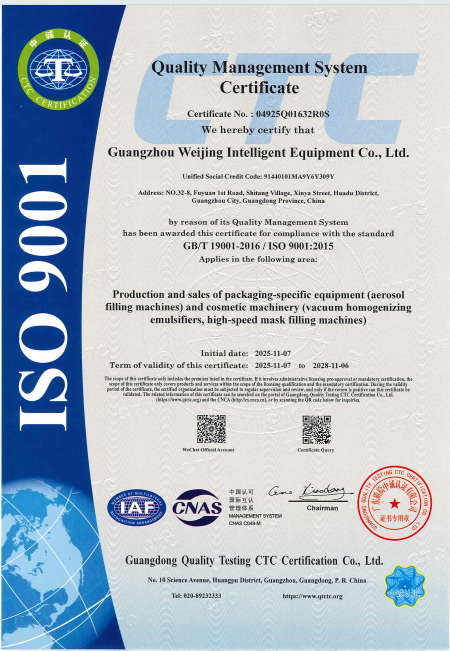

ISO9001

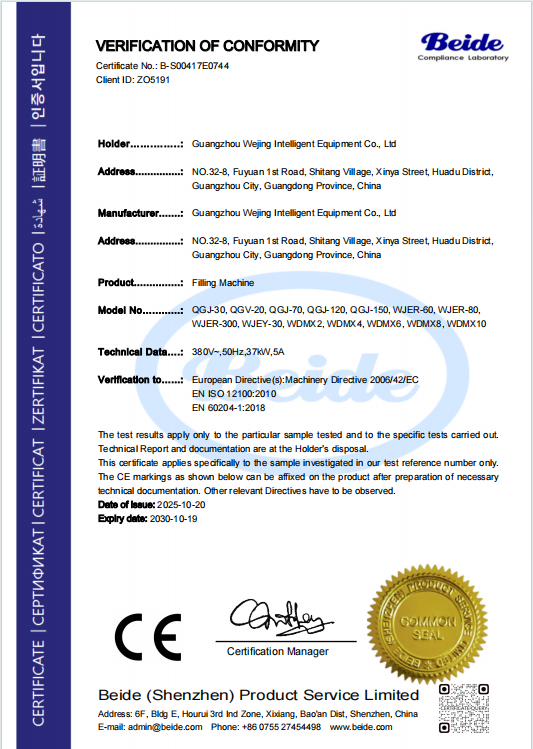

CE