Product Advantages:

1.Automated Production Process

2.High-Efficiency Capacity

3.Precision Metering System

4.Intelligent Monitoring and Control System

5.Quick Adjustment and Switching

6.Energy Efficiency

7.Rapid Maintenance and Switching

8.Quality Inspection and Traceability System

9.Human-Machine Interface

10.Automatic Maintenance System

Technical Parameters:

Technical Parameter | Description |

Filling capacity (cans/min) | 40-50 |

Liquid filling volume (ml) | 10-600( can be customized) |

Gas filling volume (ml) | 10-600( can be customized) |

Filling heads | 2 heads |

Filling accuracy | ≤±1% |

Applicable cans diameter (mm) | 35 - 70( can be customized) |

Applicable cans height (mm) | 80 - 300( can be customized) |

Applicable valve | 1 inch |

Working pressure (Mpa) | 0.6 - 0.8 |

Max gas consumption (m3/min) | 5 |

Power (KW) | 7.5 |

Dimension (LWH) mm | 22000*3500*2000 |

Material | SS304 ( some parts can be SS316) |

Warranty | 1 year |

Key Selling Points | High speed fully automatic high production |

Maintenance Requirements | Recommended maintenance procedures and schedules |

Certifications and Standards | CE&ISO9001 |

Detailed Images:

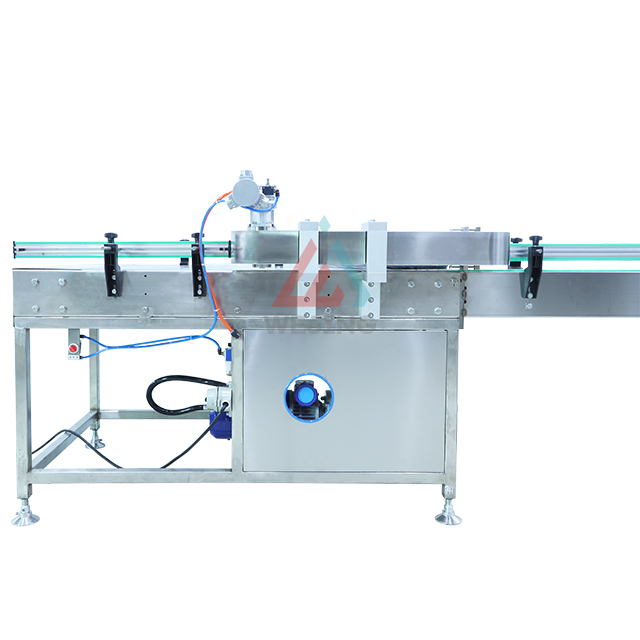

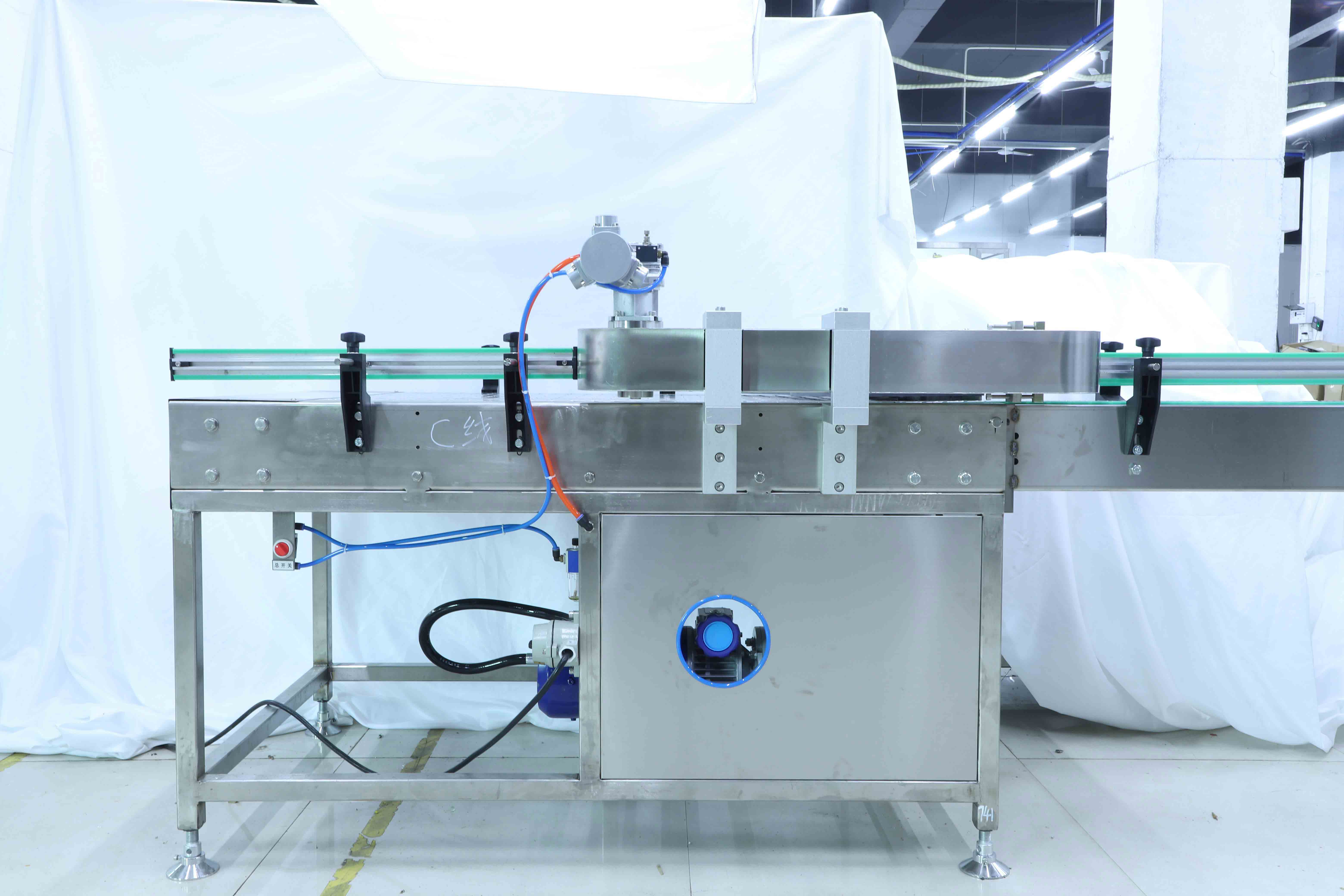

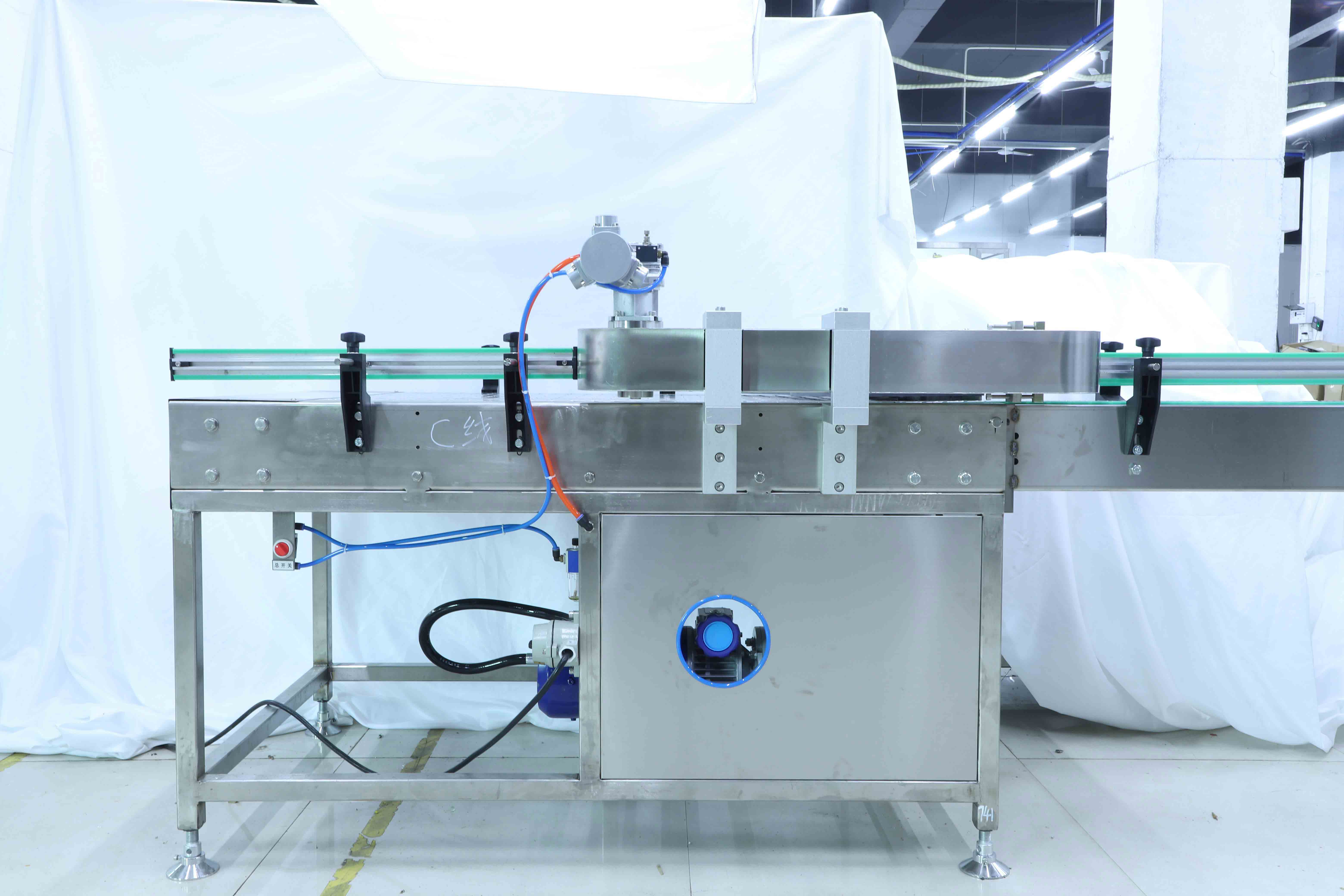

Auto Can Feeding Machine:

Variable speed bottle feeding table is the basic feeding system of aerosol spray bottle filling line, operator will put empty bottles on the table, with gear motor driving, the bottle will be arranged to the conveyor, the machine will be able to work with different size bottle.

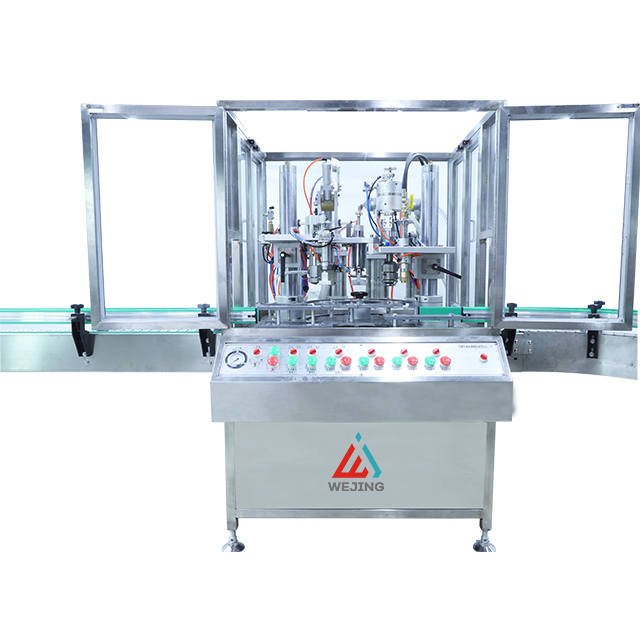

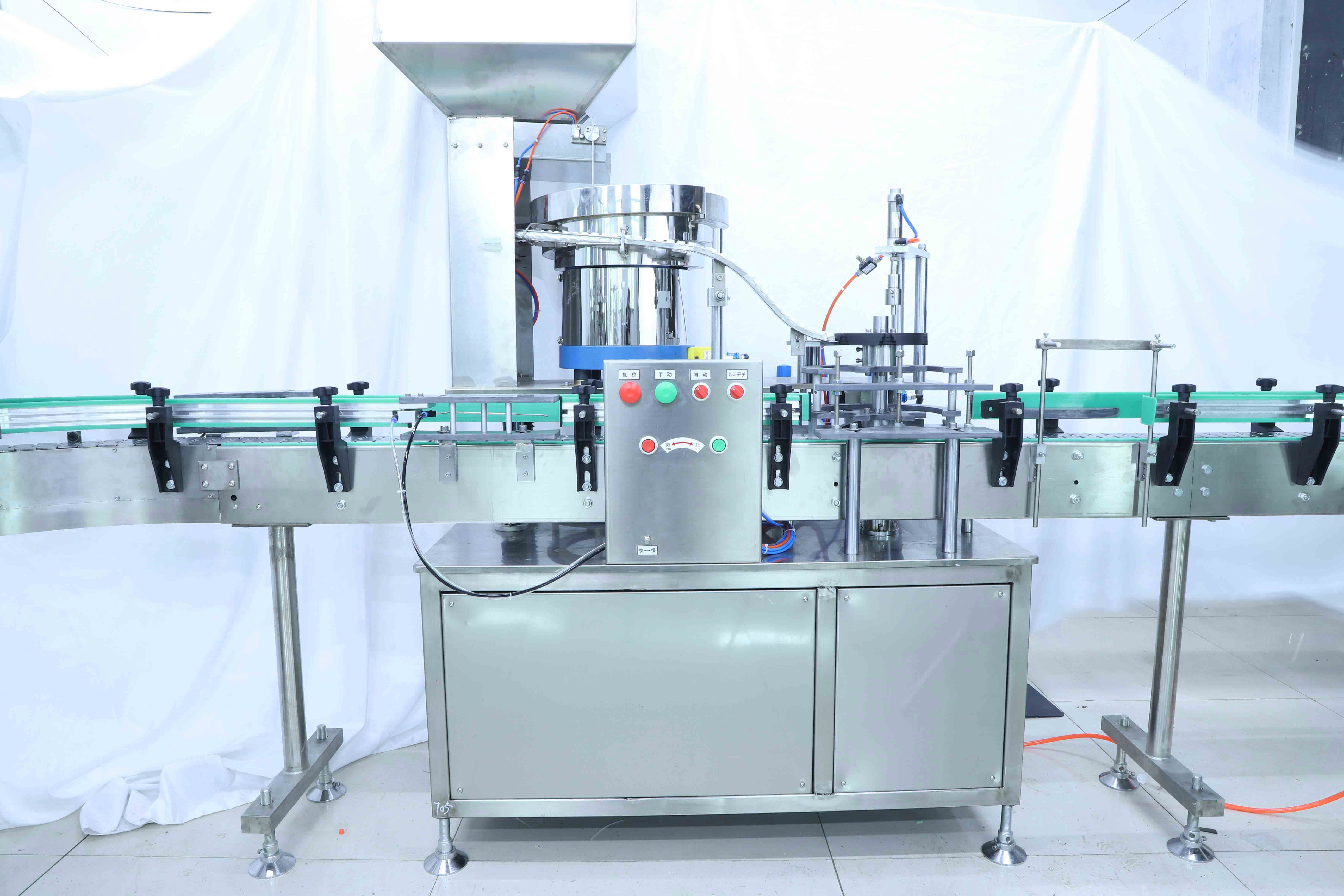

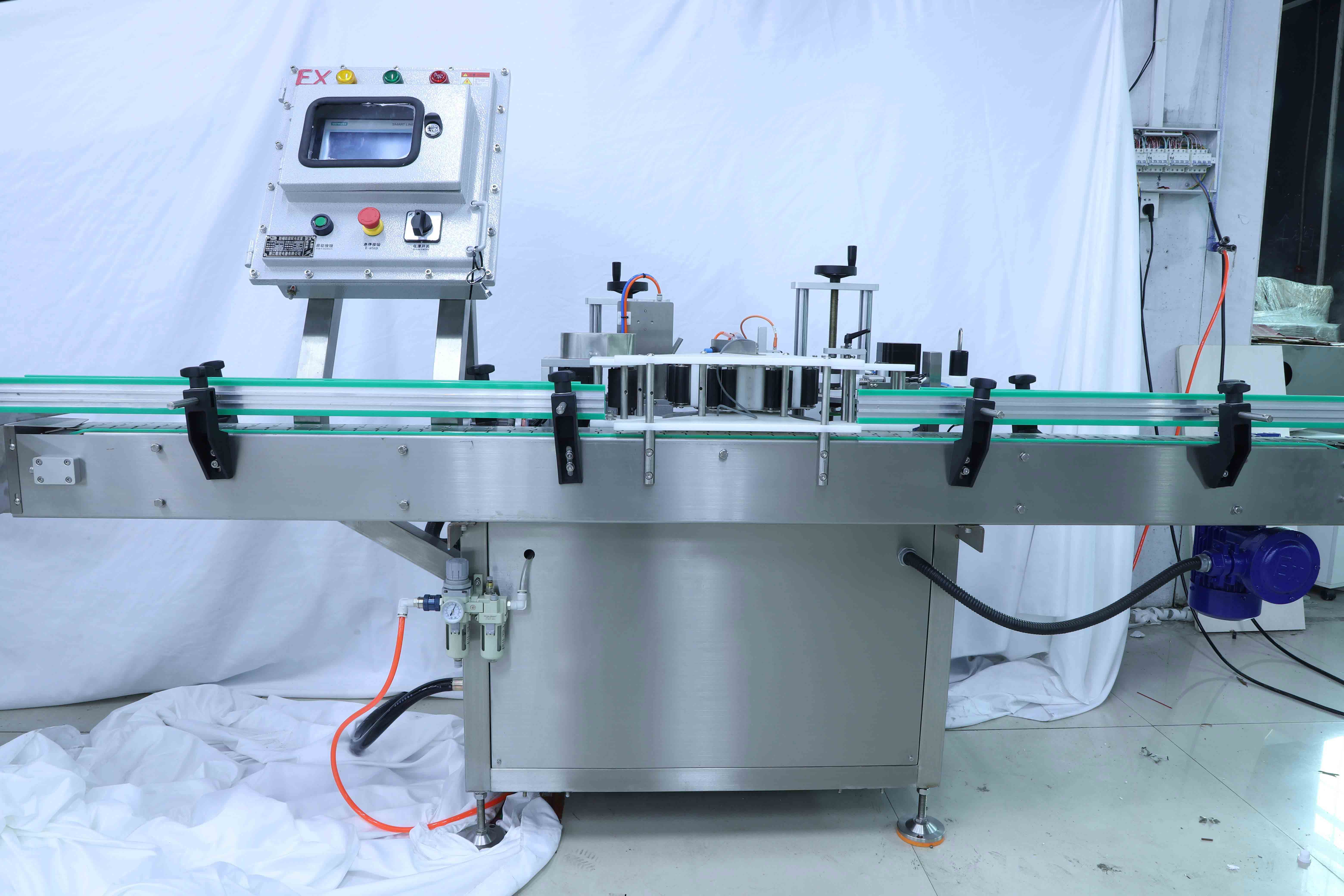

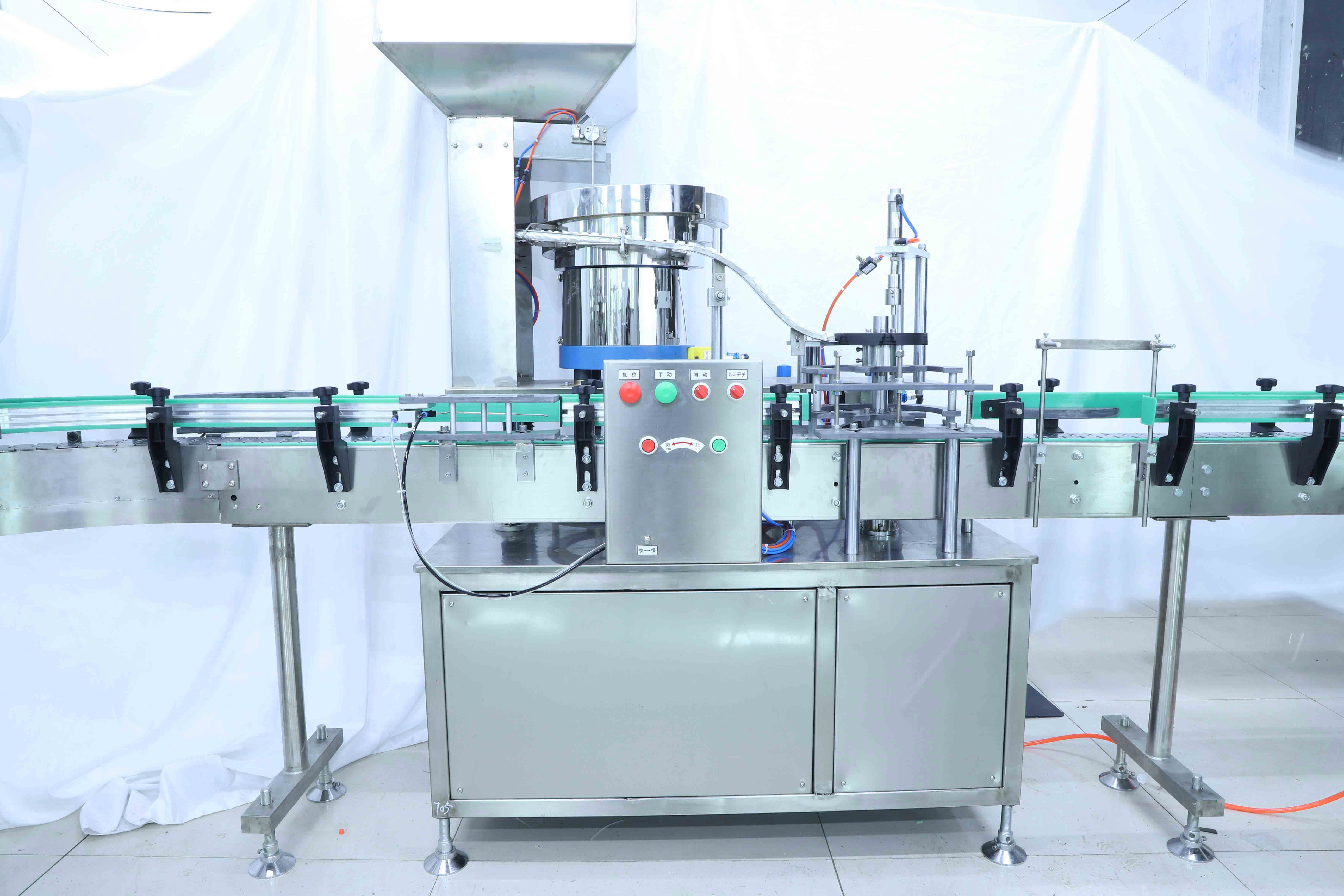

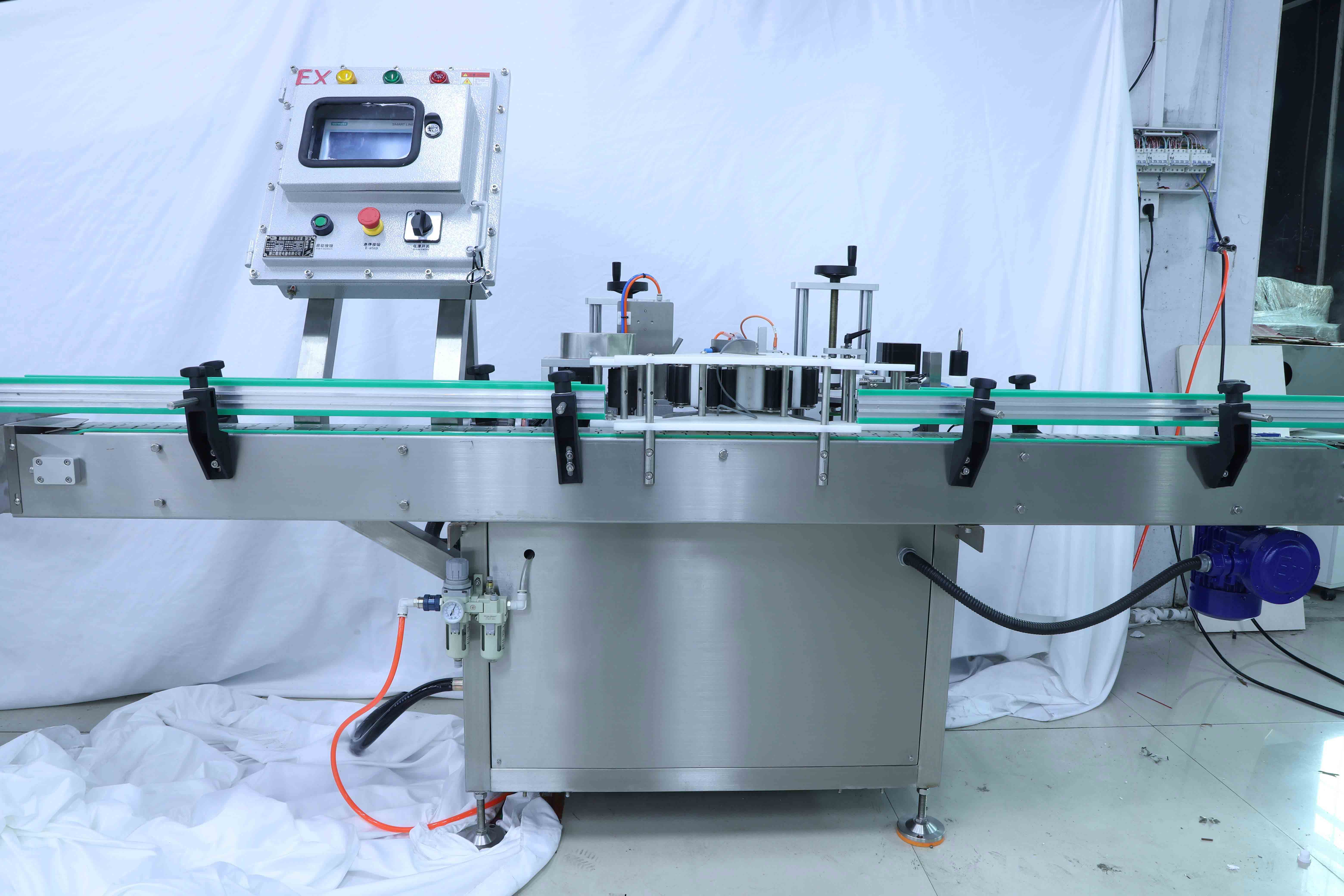

Aerosol Filling Sealing Production Line:

QGJ70 Automatic aerosol filling production line is made up of a rotary table featuring liquid filling heads, insert valves, crimping heads and gas filling heads, a compressed air piston pump, a conveyor belt, etc.

It is automatic and with high-efficiency,It will not fill materials without empty cans.And the filling accuracy is over 99%.

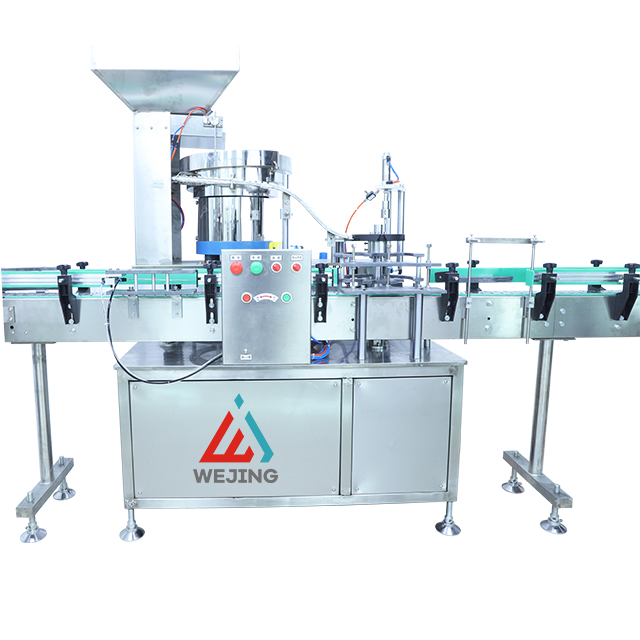

Auto Actuator Fixed Machine:

The machine is easy to adjust, and the height can be changed by lifting the handle. For different diameter cans, just need to replace the star wheel molds.

Auto Tube Stick Machine:

Automatically attach the tube to the aerosol bottle. It can be used in different kinds of aerosol cans. High automation, convenient operation, safe and reliable, it is the ideal choice for the manufacturers of aerosol cans.

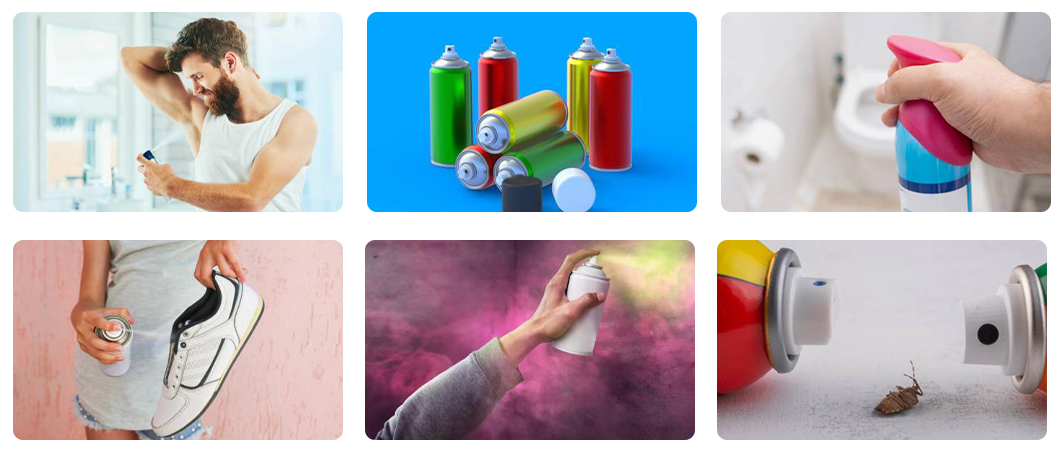

Products Show:

Packing and Delivery:

Machine packing inside is plastic films and outside is fumigation wooden case.

Our wooden case is very strong,it can bear long time shipping on the sea.

And machine with preservative film, it can stop the salt sea water enter into the machine and make the machine corrosion.

Our Service:

Pre-sale services:

1. Providing professional technical support.

2. Send the product catalog and instruction manual.

3. If you have any question PLS contact us online or send us email, we promise we will give you a reply at the first time!

4. Personal call or visit are warmly welcome.

Sale of services:

1. We promise honest and fair, it's our pleasure to serve you as your purchasing consultant.

2. We guarantee punctuality, quality and quantities strictly implement the terms of contract.

After-sales service:

1. Where to buy our products for 1 years warranty and life long maintenance.

2. A large stock of components and parts, easily-worn parts.