The filling volume of the equipment can be flexibly adjusted within the range of 10-1200ml, the filling speed is maintained at a stable rate of 60-70 bottles / minute, and the filling accuracy is strictly controlled within ±1%, which can efficiently meet the demand forlarge-scale production of aerosol products from small batch to medium batch, and it is suitable for the aerosol filling scenarios in a snow spray, aerosol paint,etc.

|Technical Parameters

1 | Filling capacity | 60-70cans/min |

2 | Liquid filling volume | 10-1200 ml ( can be customized) |

3 | Gas filling volume | 10-1200ml( can be customized) |

4 | Filling heads | 1 glass ball placing head 4 liquid heads 1 valve Inserting head |

5 | Filling accuracy | ≤±1% |

6 | Applicable cans diameter | 35 - 70mm( can be customized) |

7 | Applicable cans height (mm) | 80 - 300mm( can be customized) |

8 | Applicable valve | 1 inch |

9 | Working pressure | 0.6 - 0.8Mpa |

10 | Max gas consumption | 5m3/min |

11 | Material | SS304 ( some parts can be SS316) |

|

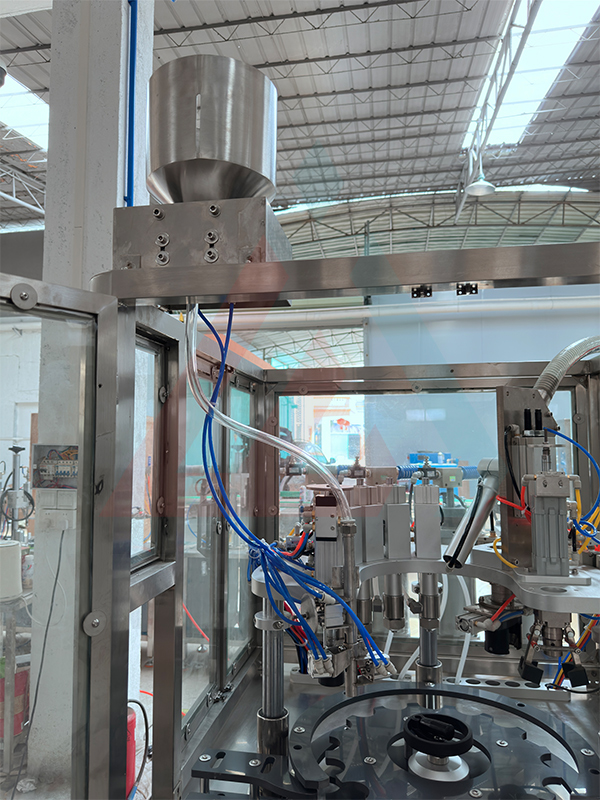

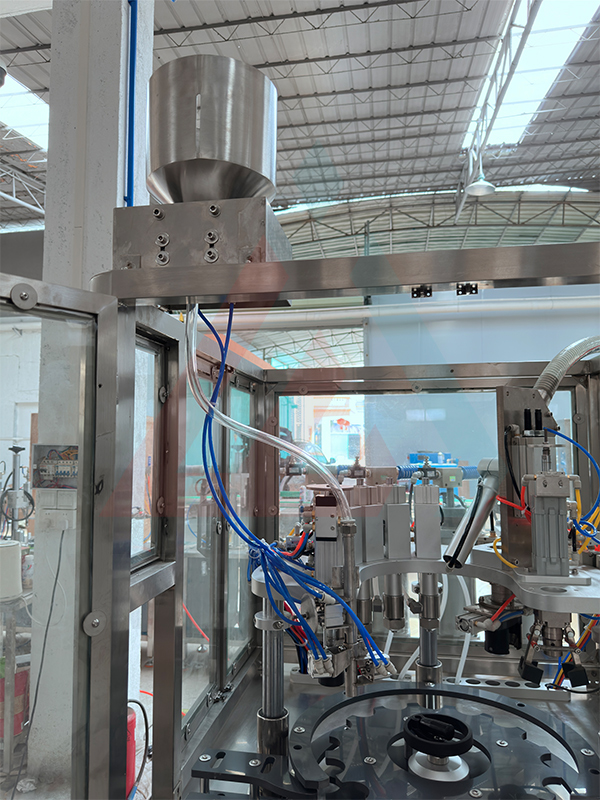

Detail Image

Glass ball placing

Responsible for placing glass beads into the aerosol can in set quantities.

Equipped with high precision vibration plate and positioning track to ensure the glass beads fall into the aerosol can accurately and avoid jamming or leakage

Liquid Filling

Responsible for filling precise amounts of liquid material into empty bottles.

Adopts guided filling with anti-drip design, and the contact surface is made of 316L stainless steel, which is corrosion-resistant and easy to clean.

Valve inserting

Responsible for inserting valbe into the aerosol can.

Prepare for subsequent sealing and inflation,ensure that the valve is sealed and securely mounted

|Product Advantage

1) Functional integration: integrating the three major processes of glass bead release, liquid filling and valve loading into one, reducing the time of equipment connection and improving the consistency of the production line.

2)High efficiency and stability: 60-70 bottles / minute filling speed, far more than manual or semi-automatic equipment, and continuous operation for 8 hours failure rate of ≤ 0.5%.

3)Excellent accuracy: Filling accuracy is controlled at ±1%.

4)Flexible and adjustable: the filling volume of 10-1200ml stepless adjustment, support for different specifications of aerosol cans rapid change of type, change of type time ≤ 30 minutes.

5)Strong compatibility: it can be adapted with all kinds of filling machines to meet the subsequent filling needs of different projectiles (liquefied gas, compressed gas, etc.).

|

Product Packaging

Auto Aerosol Filling Machine

Wooden crate protection

Multiple modes of transportation

|Product Uses:

This machine can be used in the production of Snow spray,Aerosol Ribbons , Paint spray etc。

|Operational Principle:

1) The machine works by precisely aligning the aerosol can and the sealing component. A controlled force is applied to create a tight and secure seal. Sensors monitor the process to ensure accuracy.

2) It utilizes a mechanical clamping system to hold the can in place. And then pressed firmly to form a leak-proof seal.

3) The operational principle involves a rotational movement to evenly distribute the sealing force. This ensures a consistent seal around the entire perimeter of the can. Automatic control systems adjust parameters based on the can type and sealing requirements.

|

Comment & FAQ

1. How many operators are needed for the equipment?

How many operators are needed for the equipment?

2.How often do I need to perform maintenance?

It is recommended to clean the filling nozzle and glass bead putting track after daily production, check the transmission parts and add lubricant every month, and carry out a complete overhaul every half a year.

3. I'm new in our industry, but I'm planing to set up a factory, what can I do ?

We will design the most suitable proposal based on your actual situation, such as the daily production, raw material formula, factory layout, etc. Also we would like to introduce some excellent suppliers of raw materials, bottles, labels, etc if needed. After sales,engineer will be send to fields installation , training and commissioning

4. How can you control the quality and delivery?

All our machines will be tested before packaging. Teaching video and packing pictures will be sent to you for checking,we promise that our wooden packaging is strong enough and safety for long delivery .

5. Does the machine come with a warranty?

Yes, it comes with 2 yeas warranty period.

|

Company Profile

Guangzhou Wejing Intelligent Equipment Co., Ltd. is a high-tech enterprise specializing in the development and manufacture of automation machinery and equipment, located in No. 32, Fuyuan Road, Xinya Street, Huadu District, Guangzhou City, China, which is the most comprehensive manufacturer of filling machine specifications at present.

Guangzhou Wejing Intelligent Equipment Co., Ltd. is a high-tech enterprise specializing in the development and manufacture of automation machinery and equipment, located in No. 32, Fuyuan Road, Xinya Street, Huadu District, Guangzhou City, China, which is the most comprehensive manufacturer of filling machine specifications at present.

Since our company inception, we has been committed to providing customers around the world with efficient, intelligent and reliable filling and packaging solutions, covering a wide range of products, such as aerosol filling machines, mask machines and other areas. Our self-developed aerosol filling machine adopts advanced automation technology and is characterized by high precision, high efficiency and low loss, which can meet the filling needs of aerosol products of different specifications. The equipment is easy to operate and has strong stability. The company's internal ISO quality management system is strictly implemented, from raw materials to finished products, each link is strictly controlled. Our products are exported to Southeast Asia, America, Africa and other countries and regions, and we have established a perfect after-sales service system to provide customers with timely and professional technical support.

Guangzhou Wejing Intelligent Equipment Co., Ltd. is a high-tech enterprise specializing in the development and manufacture of automation machinery and equipment, located in No. 32, Fuyuan Road, Xinya Street, Huadu District, Guangzhou City, China, which is the most comprehensive manufacturer of filling machine specifications at present.

Guangzhou Wejing Intelligent Equipment Co., Ltd. is a high-tech enterprise specializing in the development and manufacture of automation machinery and equipment, located in No. 32, Fuyuan Road, Xinya Street, Huadu District, Guangzhou City, China, which is the most comprehensive manufacturer of filling machine specifications at present.