Product Advantage

1. High Accuracy: The Electronic Weight Checking Machine offers precise measurement, ensuring consistent filling of aerosol products and meeting quality standards.

2. Efficient Operation: With its user-friendly interface and easy-to-use controls, the machine simplifies the weighing process, reducing downtime and increasing productivity.

3. Quick Adjustment: The machine can be quickly adjusted to accommodate different product specifications, allowing for flexibility in production lines.

4. Reliability and Durability: Designed to meet industry standards, the Electronic Weight Checking Machine is built for long-lasting performance, ensuring reliability and minimizing maintenance costs.

5. Advanced Monitoring: It provides real-time monitoring and data recording features, enabling manufacturers to track production, identify potential issues, and make informed decisions for process improvement.

Technical Parameters

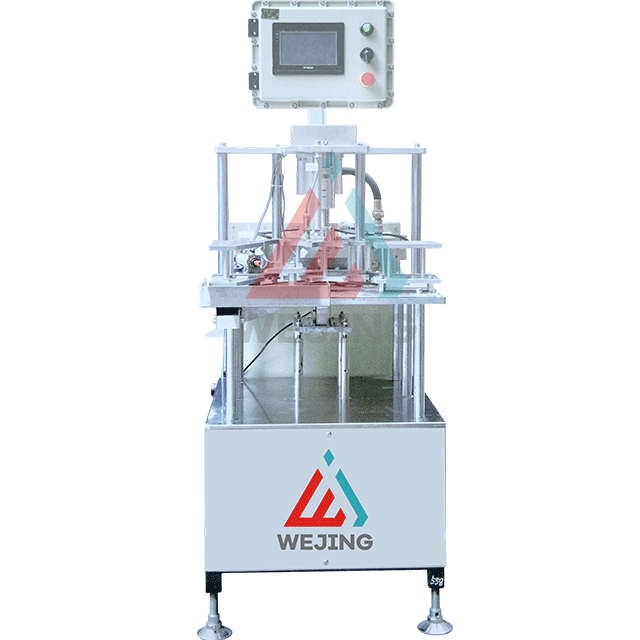

Auto Weight Checking Machine:

Allowance | ≤±1g |

Max. weight | 0-1500g |

Capacity | 60-70cans/min |

Working pressure | 0.5MPa |

Suitable can diameter | 35-73mm |

Suitable can height | 90-330mm |

Power | AC220V/50HZ |

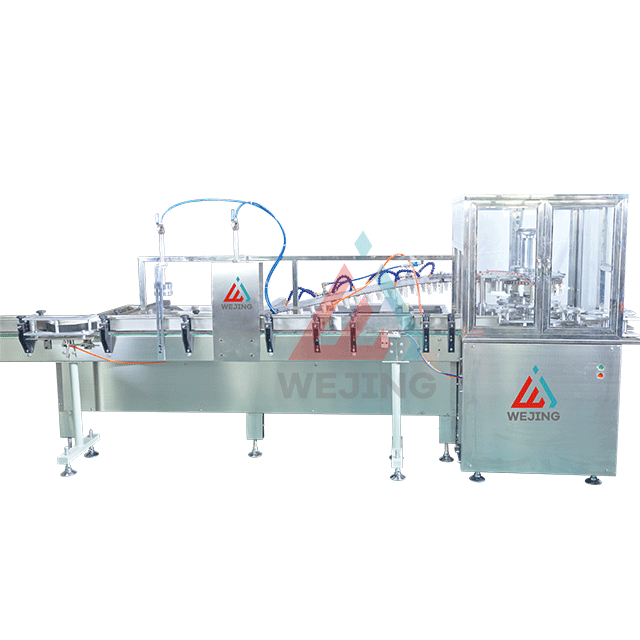

Aerosol Filling Line:

Technical Parameter | Description |

Filling capacity (cans/min) | 60-70 |

Liquid filling volume (ml) | 10-1200( can be customized) |

Gas filling volume (ml) | 10-1200( can be customized) |

Filling heads | 4 heads |

Filling accuracy | ≤±1% |

Applicable cans diameter (mm) | 35 - 70( can be customized) |

Applicable cans height (mm) | 80 - 300( can be customized) |

Applicable valve | 1 inch |

Working pressure (Mpa) | 0.6 - 0.8 |

Max gas consumption (m3/min) | 5 |

Power (KW) | 7.5 |

Dimension (LWH) mm | 22000*3500*2000 |

Material | SS304 ( some parts can be SS316) |

Warranty | 1 year |

Key Selling Points | High speed fully automatic high production |

Maintenance Requirements | Recommended maintenance procedures and schedules |

Certifications and Standards | CE&ISO9001 |

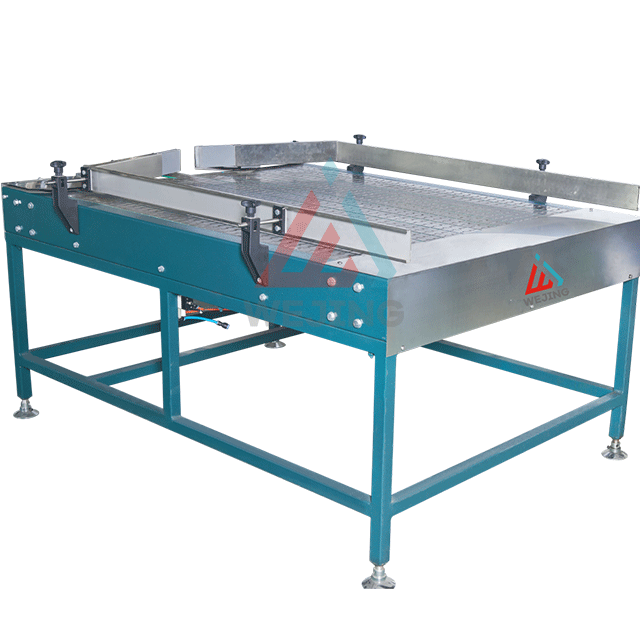

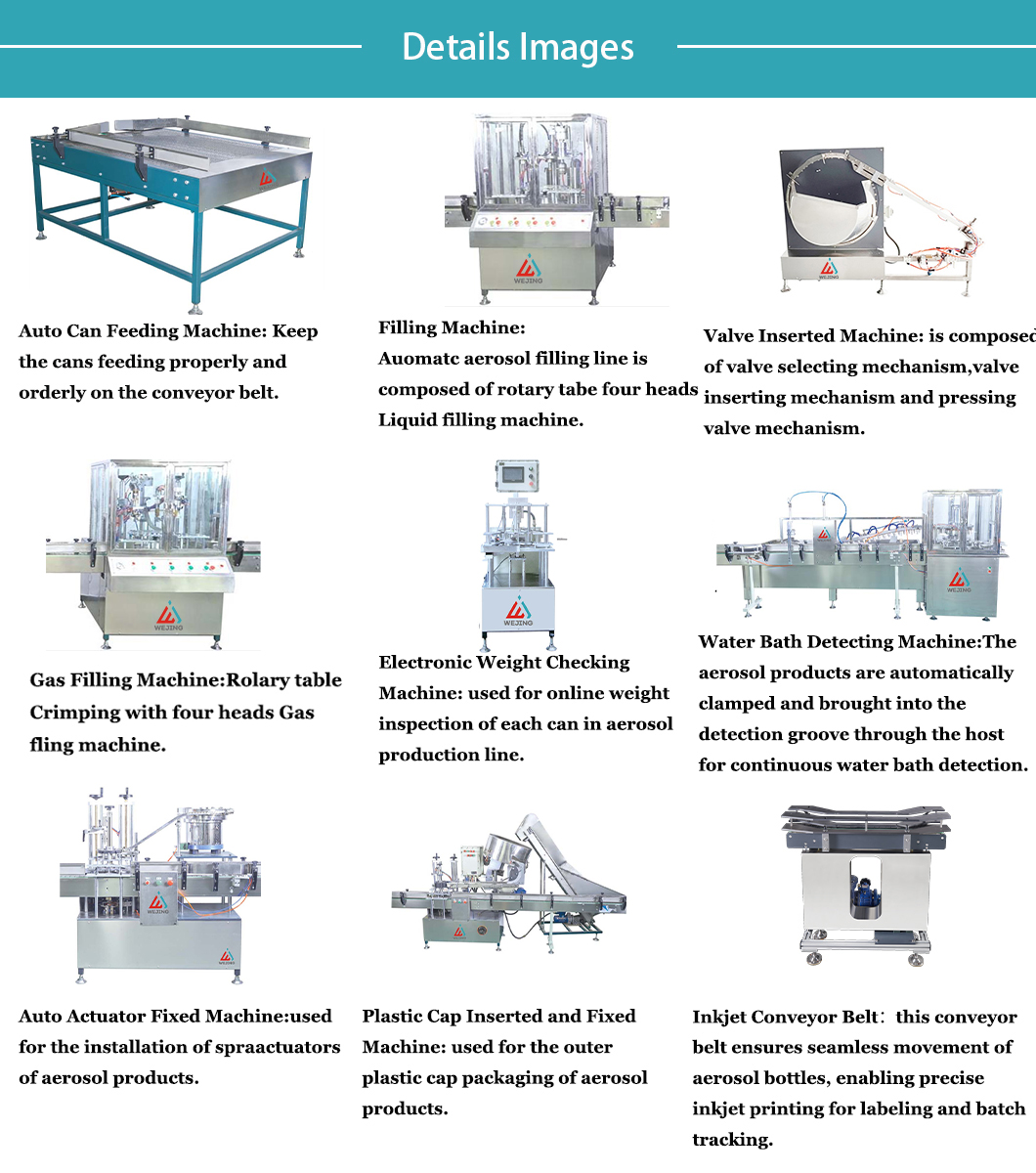

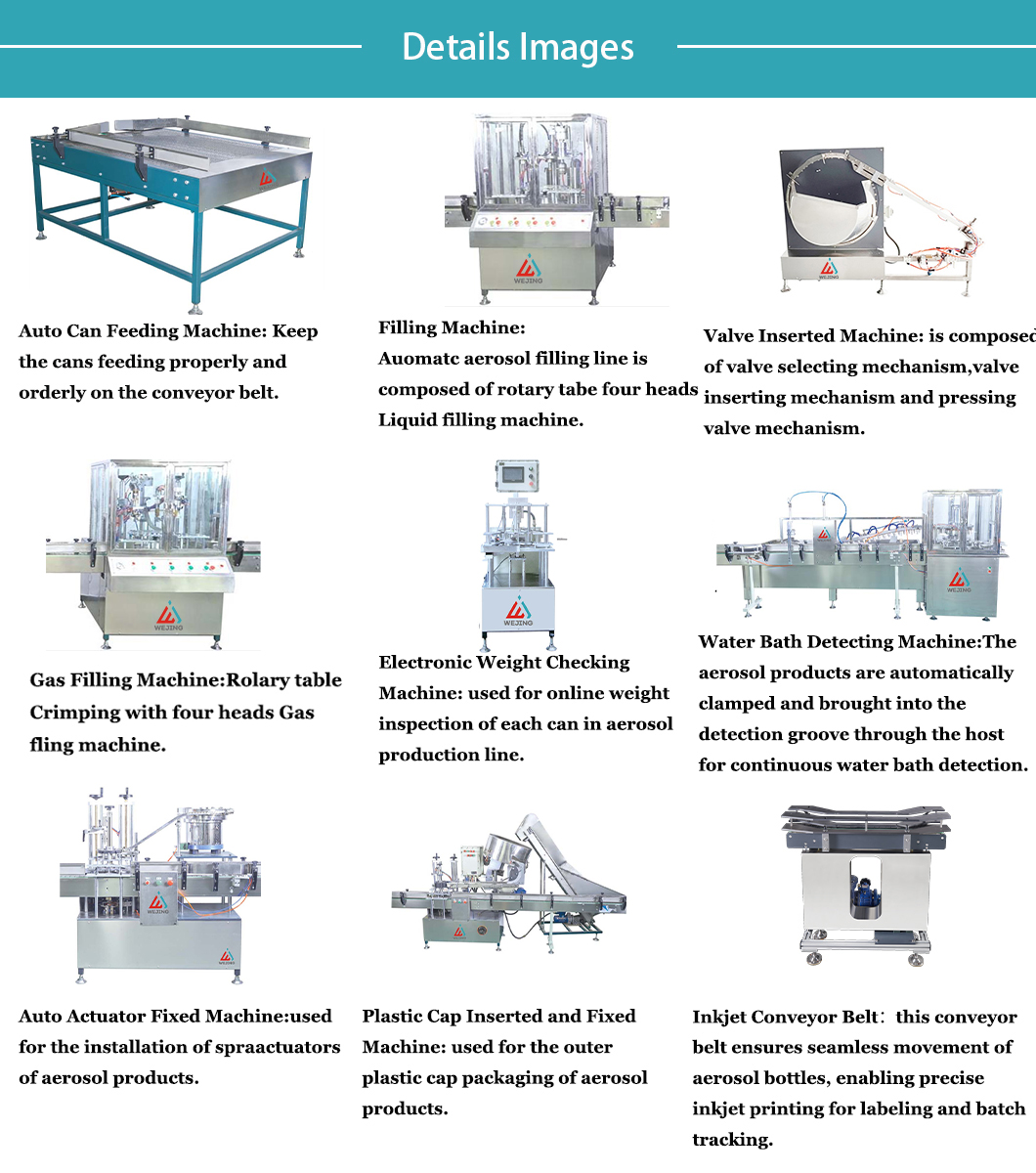

Detailed Images:

Product Uses

1. Weighing and filling: Precisely measures and fills aerosol products to ensure accurate dosing.

2. Quality control: Helps maintain consistent product weight and quality.

3. Production monitoring: Tracks production data for better process control.

4. Adjustment and calibration: Facilitates quick adjustments and calibrations for different product specifications.

5. Compliance: Ensures compliance with weight regulations and standards.

Product Operate Guide

1. Power on/off: Switch on the machine and wait for it to boot up.

2. Calibration: Calibrate the machine using standard weights for accurate measurements.

3. Product setup: Select the appropriate product settings and parameters.

4. Weighing and filling: Place the aerosol product on the weighing platform, and the machine will automatically weigh and fill it.

5. Maintenance and cleaning: Regularly clean and maintain the machine to ensure its proper functioning.

FAQ

1. What is the Electronic Weight Checking Machine used for?

It is designed for aerosol products filling lines to ensure accurate weight measurement.

2. How does the machine work?

It uses electronic sensors to weigh the aerosol products and checks if the weight is within the specified range.

3. Can the machine be integrated with other equipment?

Yes, it can be easily integrated into the production line to enhance efficiency.

4. Is the machine easy to operate and maintain?

Yes, it has a user-friendly interface and requires minimal maintenance.

5. Does the machine come with a warranty?

Most models come with a warranty to cover any manufacturing defects or malfunctions.