Working Princeple:

This sequence starts from the can feeding machine, followed by an automatic filling process, and the filling amount can be customized. Next is the automatic valve insertion, stabilization, and fixation, as well as the automatic rolling sealing mechanism. Subsequently, inflation is carried out, followed by actuator fixed, and then the tube sticking machine is used for tube sticking, all of which are mechanically completed. Finally, these items are ready for manual packaging before shipment.

Technical Parameters:

Technical Parameter | Description |

Filling capacity (cans/min) | 40-50 |

Liquid filling volume (ml) | 10-600( can be customized) |

Gas filling volume (ml) | 10-600( can be customized) |

Filling heads | 2 heads |

Filling accuracy | ≤±1% |

Applicable cans diameter (mm) | 35 - 70( can be customized) |

Applicable cans height (mm) | 80 - 300( can be customized) |

Applicable valve | 1 inch |

Working pressure (Mpa) | 0.6 - 0.8 |

Max gas consumption (m3/min) | 5 |

Power (KW) | 7.5 |

Dimension (LWH) mm | 22000*3500*2000 |

Material | SS304 ( some parts can be SS316) |

Warranty | 1 year |

Key Selling Points | High speed fully automatic high production |

Maintenance Requirements | Recommended maintenance procedures and schedules |

Certifications and Standards | CE&ISO9001 |

Detailed Images:

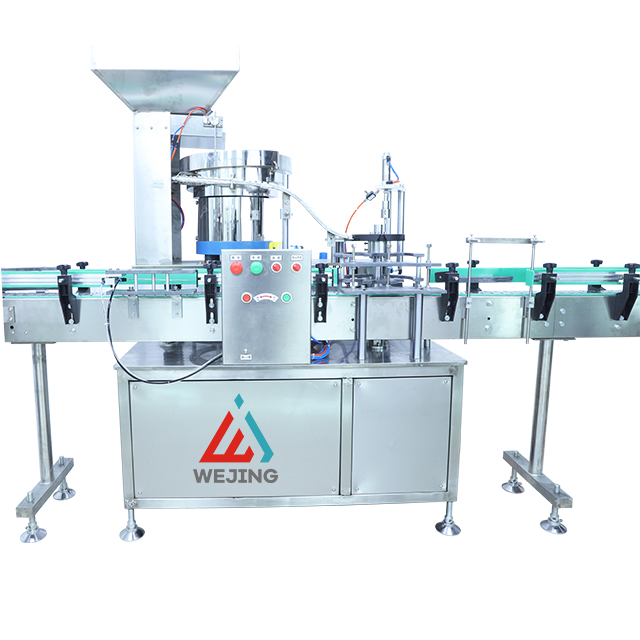

Auto Can Feeding Machine:

It is capable of ensuring the smooth operation of the bottles in the production line. High efficiency is achieved and labor intensity is decreased.

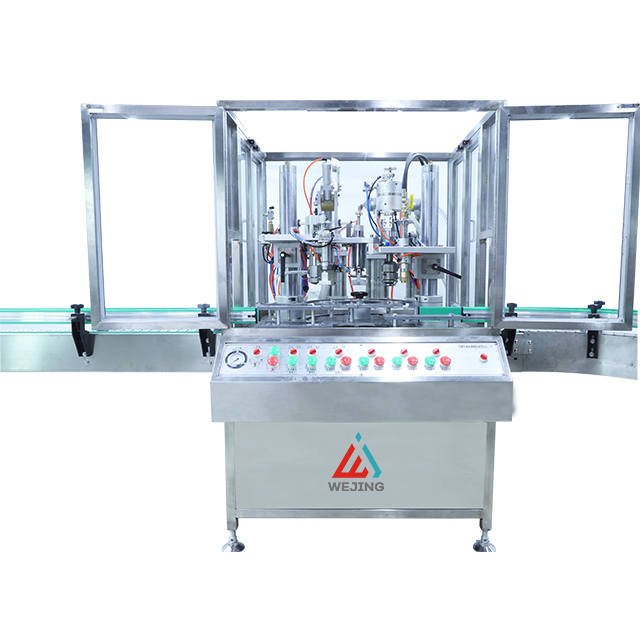

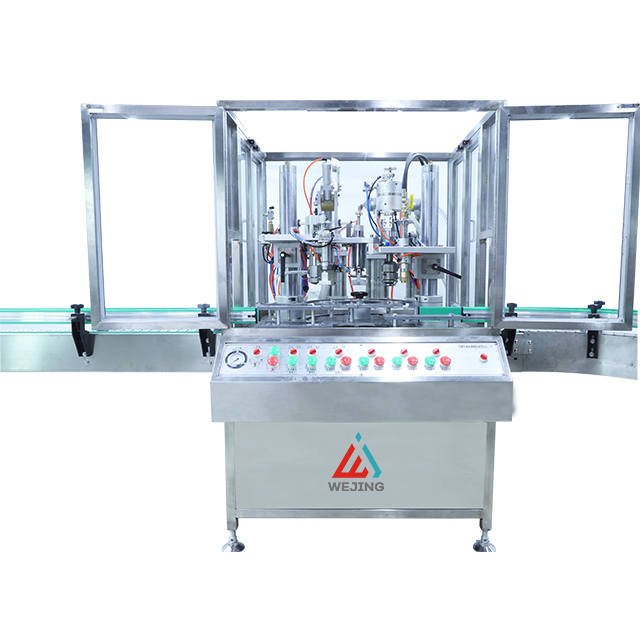

Aerosol Filling Sealing Production Line:

QGJ70 Automatic aerosol filling production line is made up of a rotary table featuring liquid filling heads, insert valves, crimping heads and gas filling heads, a compressed air piston pump, a conveyor belt, etc.

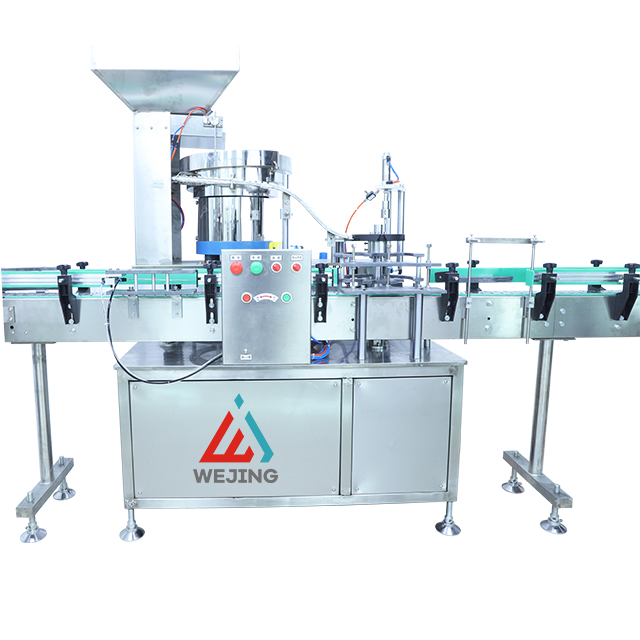

Auto Actuator Fixed Machine:

The auto actuator fixing machine is utilized for the installation of spray actuators of aerosol products.

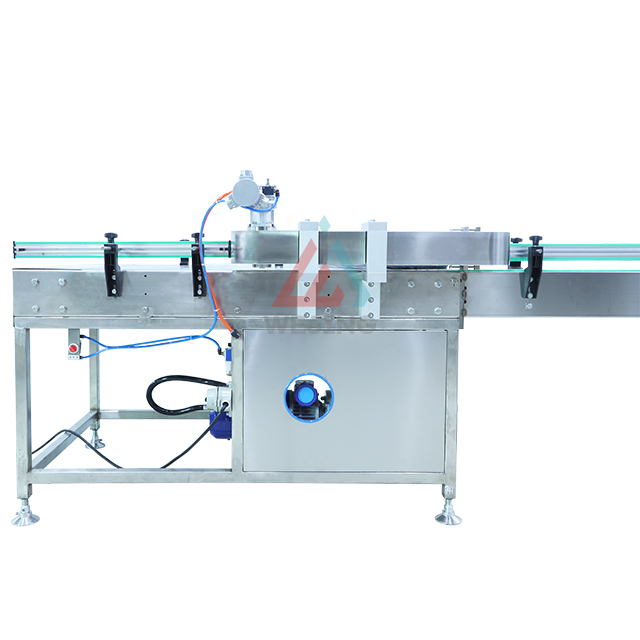

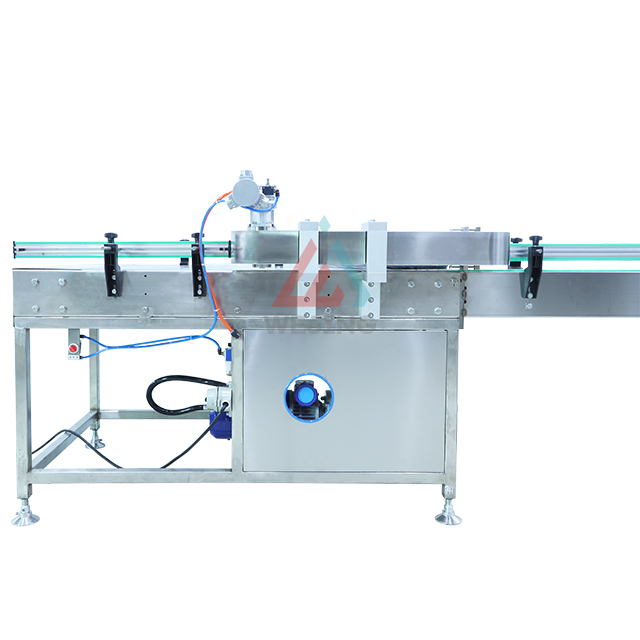

Auto Tube Stick Machine:

Automatically attach the tube to the aerosol bottle.

Products Show:

Our Service:

1. Quality Assurance: The machine is fabricated from stainless S304 material and features a novel design. The quality, specification, and functionality all comply with the requirements of the contract. We ensure a warranty period of at least one year.

2. Training: Our company provides technical training to customers. The training content covers the structure and maintenance of the equipment as well as its operation. Training is conducted in the format of online video. Qualified technicians will guide and establish the training course. After the training, the technicians of the buyer can master the operation and maintenance of the machine, and they can also master the adjustment of the process and handling various failures.

3. We are capable of customizing the machines based on customers' demands.

4. We can assist customers in handling the entire process of producing daily cosmetics, ranging from raw materials, packages, decoration machines, etc.

5. We have professional engineers ready to assist you with machine maintenance and installation problems at any time.

6. Our response is highly prompt. Our sales team works around the clock. If you have any questions about the machines, they will respond to you shortly and provide a solution within 8 hours.

7. Can assist with formulation, packaging, and raw material problems.

8. Can test the machine before placing an order.