Product Advantage:

1. Production Capacity Surge: Full automatic aerosol filling machines, with their expedited functioning, significantly enhance production potential when juxtaposed with manual or semi-automatic alternatives.

2. Precise Fill Management: The integration of sophisticated automation into these machines guarantees exact fill volumes in every canister, curbing waste, sustaining homogeneity between batches, and thereby boosting product superiority.

3. Optimal Labor Deployment: Automation greatly diminishes reliance on manual labor, lowering operational expenditures and redirecting workforce to more skilled assignments, collectively enhancing the operational fluidity.

4. Enhanced Safety Framework: Specifically constructed to isolate potentially dangerous procedures and materials, these machines markedly decrease operator risk exposure and conform to strict safety regulations outlined by industry bodies.

5. Adaptive and Scalable Design: Accommodating a range of can dimensions and product categories, full automatic aerosol filling systems deftly adapt to market fluctuations. Their upgrade potential ensures your production line stays ahead, prepared for future industry demands.

Technical Parameters:

Technical Parameter | Description |

Filling capacity (cans/min) | 60-70 |

Liquid filling volume (ml) | 10-1200( can be customized) |

Gas filling volume (ml) | 10-1200( can be customized) |

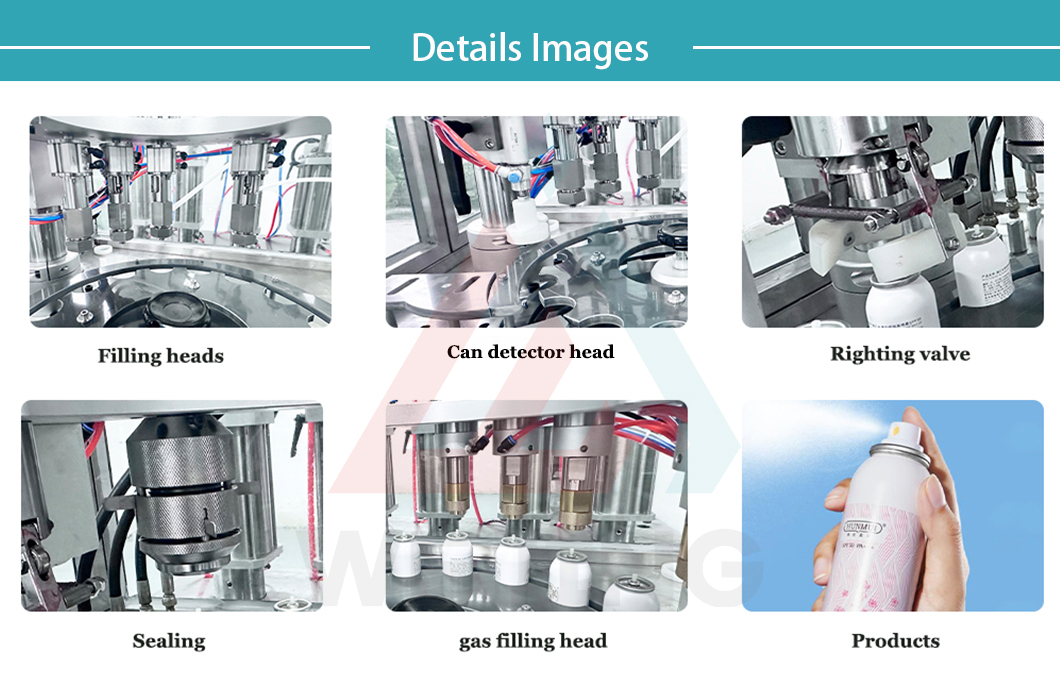

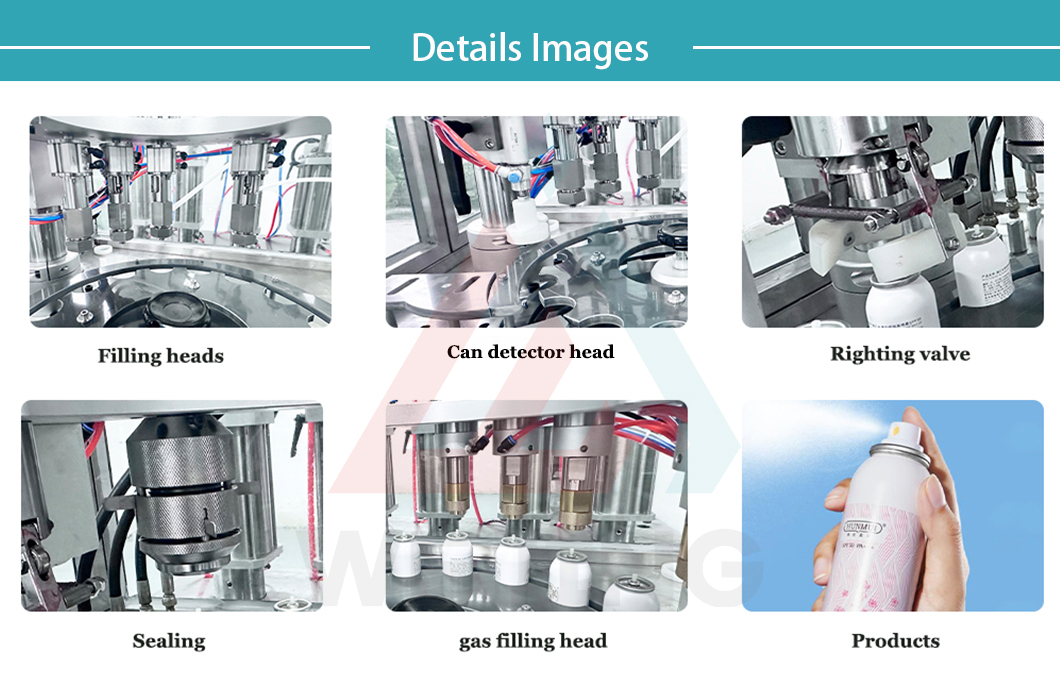

Filling heads | 4 heads |

Filling accuracy | ≤±1% |

Applicable cans diameter (mm) | 35 - 70( can be customized) |

Applicable cans height (mm) | 80 - 300( can be customized) |

Applicable valve | 1 inch |

Working pressure (Mpa) | 0.6 - 0.8 |

Max gas consumption (m3/min) | 5 |

Power (KW) | 7.5 |

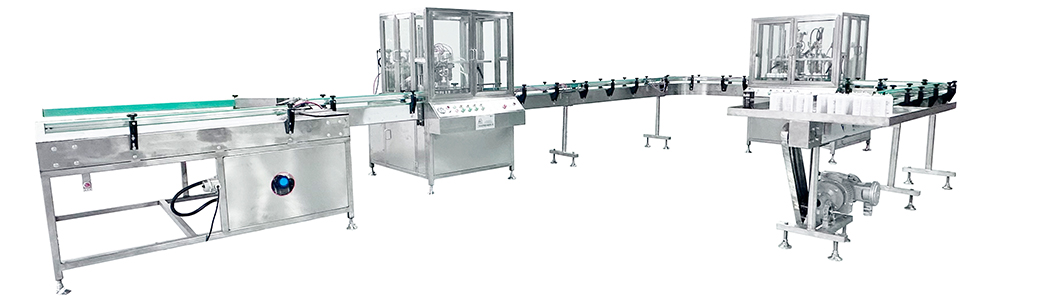

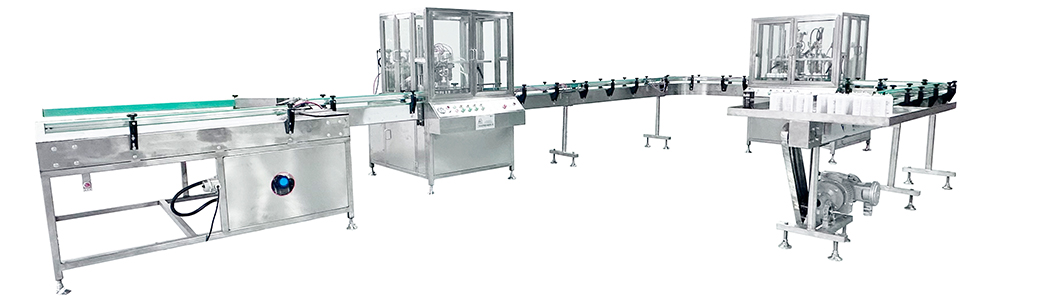

Dimension (LWH) mm | 22000*3500*2000 |

Material | SS304 ( some parts can be SS316) |

Warranty | 1 year |

Key Selling Points | High speed fully automatic high production |

Maintenance Requirements | Recommended maintenance procedures and schedules |

Certifications and Standards | CE&ISO9001 |

Detailed Images:

Product Operate Guide:

1. Preliminary Inspection Routine: Prior to startup, ascertain that all parts are pristine, adequately lubricated, and perfectly aligned. Validate material levels and perform an exhaustive visual check of the entire equipment.

2. Calibration & Settings Tuning: Harness the Human-Machine Interface (HMI) to input exact filling parameters, specifically volume, pressure settings, and conveyor velocity, customized to the precise needs of your product.

3. Can Loading Protocol: Gently introduce cans into the feeding mechanism, confirming their correct alignment and absence of damage. If prerequisite, attach lids securely in anticipation of the filling stage.

4. Commencement of Production Run: Initiate the manufacturing cycle by activating the 'start' command on the control panel, prompting the machinery to autonomously execute a pre-established sequence of filling, sealing, and gas-infusion tasks.

5. Ongoing Quality Assurance & Optimization: Regularly examine finished aerosols for leak tightness, uniform weight, and secure crimping. Keep vigilant oversight of the machine's operation and leverage instantaneous data analysis to facilitate necessary adjustments.

FAQ:

1. Space Requirement for U-shaped Aerosol Filler:

No, its space-efficient U-layout minimizes the footprint, rendering it ideal even for space-constrained production environments.

2. Versatility in Handling Product Thickness:

Indeed, the machine is engineered to manage a broad viscosity spectrum, from thin to thick fluids, enhancing production flexibility.

3. Ease of Cleaning and Upkeep:

Certainly, its design with accessible components and modularity facilitates effortless cleaning and streamlined maintenance procedures.

4. Method for Achieving Filling Precision:

The employment of high-resolution sensors and advanced control mechanisms ensures uniform filling volumes and reduces product loss, thereby maintaining accuracy.

5. Customization for Particular Production Demands:

Yes, numerous manufacturers provide customization services to adapt the machine to individual production demands, assuring peak performance.