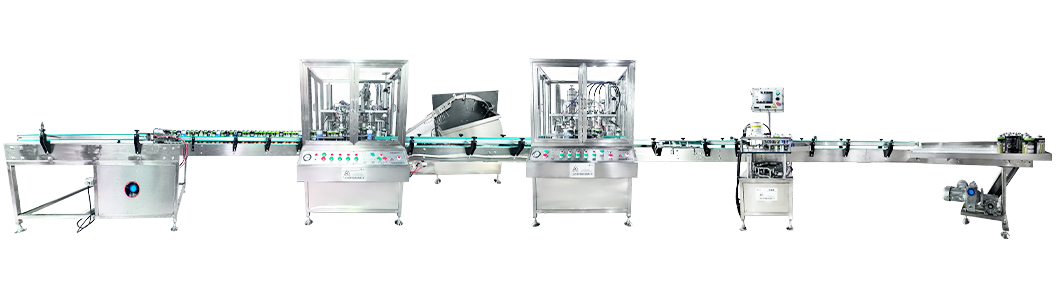

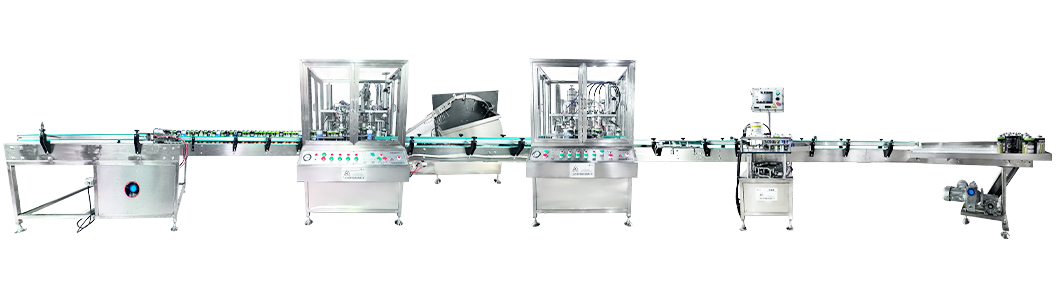

Operation Process:

Aerosol can feeding table --- Automatic conveyor cans input --- Can detector head & Automatic liquid filling & Automatic insert valve & Correcting valve --- Automatic air inflating and crimping --- Weight checking----Worktable

Technical Parameters:

Technical Parameter | Description |

Filling capacity (cans/min) | 60-70 |

Liquid filling volume (ml) | 10-1200( can be customized) |

Gas filling volume (ml) | 10-1200( can be customized) |

Filling heads | 4 heads |

Filling accuracy | ≤±1% |

Applicable cans diameter (mm) | 35 - 70( can be customized) |

Applicable cans height (mm) | 80 - 300( can be customized) |

Applicable valve | 1 inch |

Working pressure (Mpa) | 0.6 - 0.8 |

Max gas consumption (m3/min) | 5 |

Power (KW) | 7.5 |

Dimension (LWH) mm | 22000*3500*2000 |

Material | SS304 ( some parts can be SS316) |

Warranty | 1 year |

Key Selling Points | High speed fully automatic high production |

Maintenance Requirements | Recommended maintenance procedures and schedules |

Certifications and Standards | CE&ISO9001 |

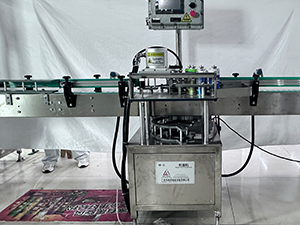

Detailed Images:

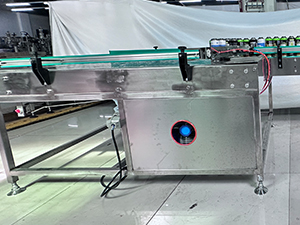

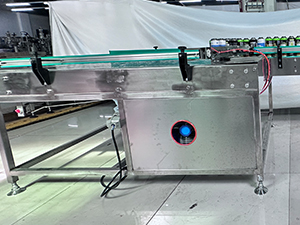

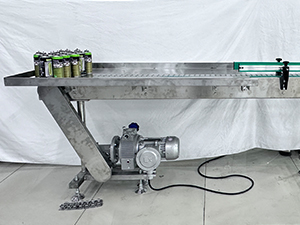

Auto Can Feeding Machine:

Aerosol products production normally needs to run fast from the cans feeder machine. To let the cans move quickly, there are 13 flat-roofed conveyor belts and an explosion-proof motor to change the transporting speed.

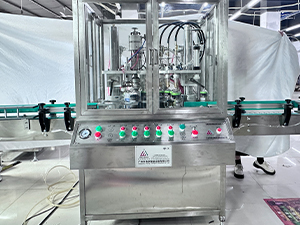

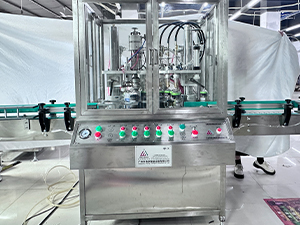

Liquid Filling Machine:

There are 4 liquid filling heads, which can meet the needs of users to fill materials of multiple colors or properties at the same time. Moreover, it is very easy to clean up each filling head. These two features make this automatic liquid filling machine is the best automatic filling equipment.

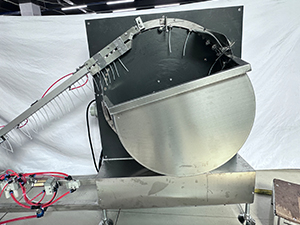

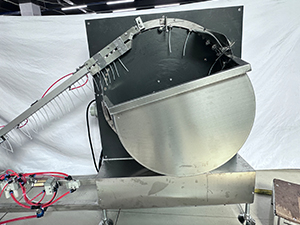

Insert Valve:

This automatic valve insert is divided into 3 parts which include valve sorting turntable, valve blowing part and valve placing part.

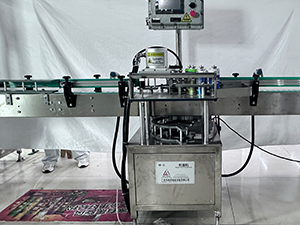

Crimping and Gas Filling Machine:

This automatic aerosol filling machine is equipped with 4 gas filling heads on one workbench respectively. Each filling head is controlled by the corresponding filling cylinder, the gas filling volume and filling speed, the smaller gas filling volume the higher filling accuracy. Users can filling 4 different kinds of gas or filling one kind of gas at the same time.

Weight Checking Machine:

This high-speed automatic aerosol weight check machine is designed with a stable and highly sensitive weighing sensor and signal acquisition instrument. It aimed to carry out high-speed operation processing by applying a PLC.

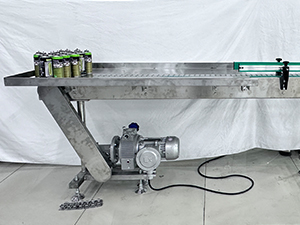

Packing Table:

Suitable for the production of various aerosol products in diverse industries including cosmetics, pharmaceuticals, household care, industrial & institutional care, auto care, etc.

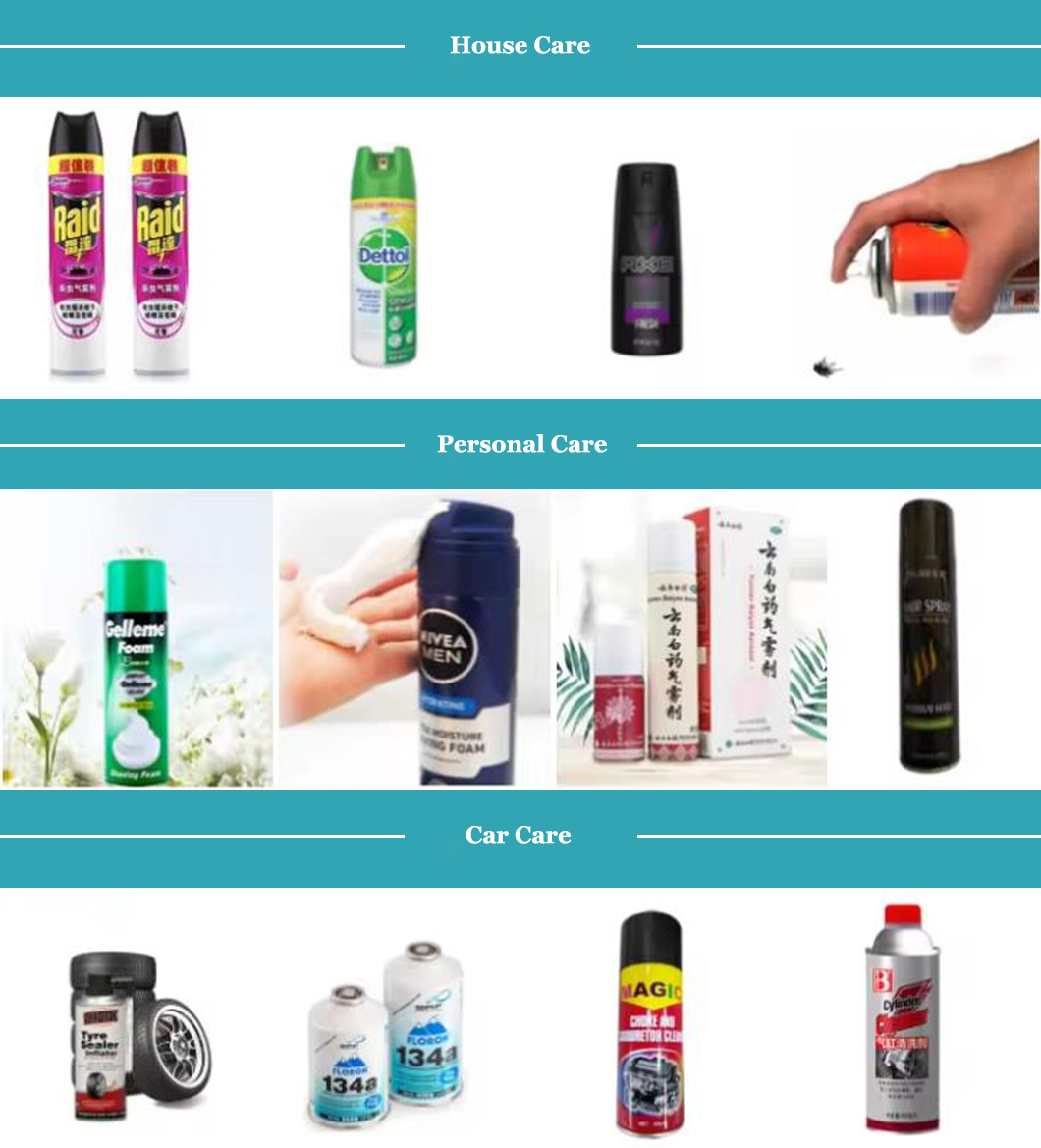

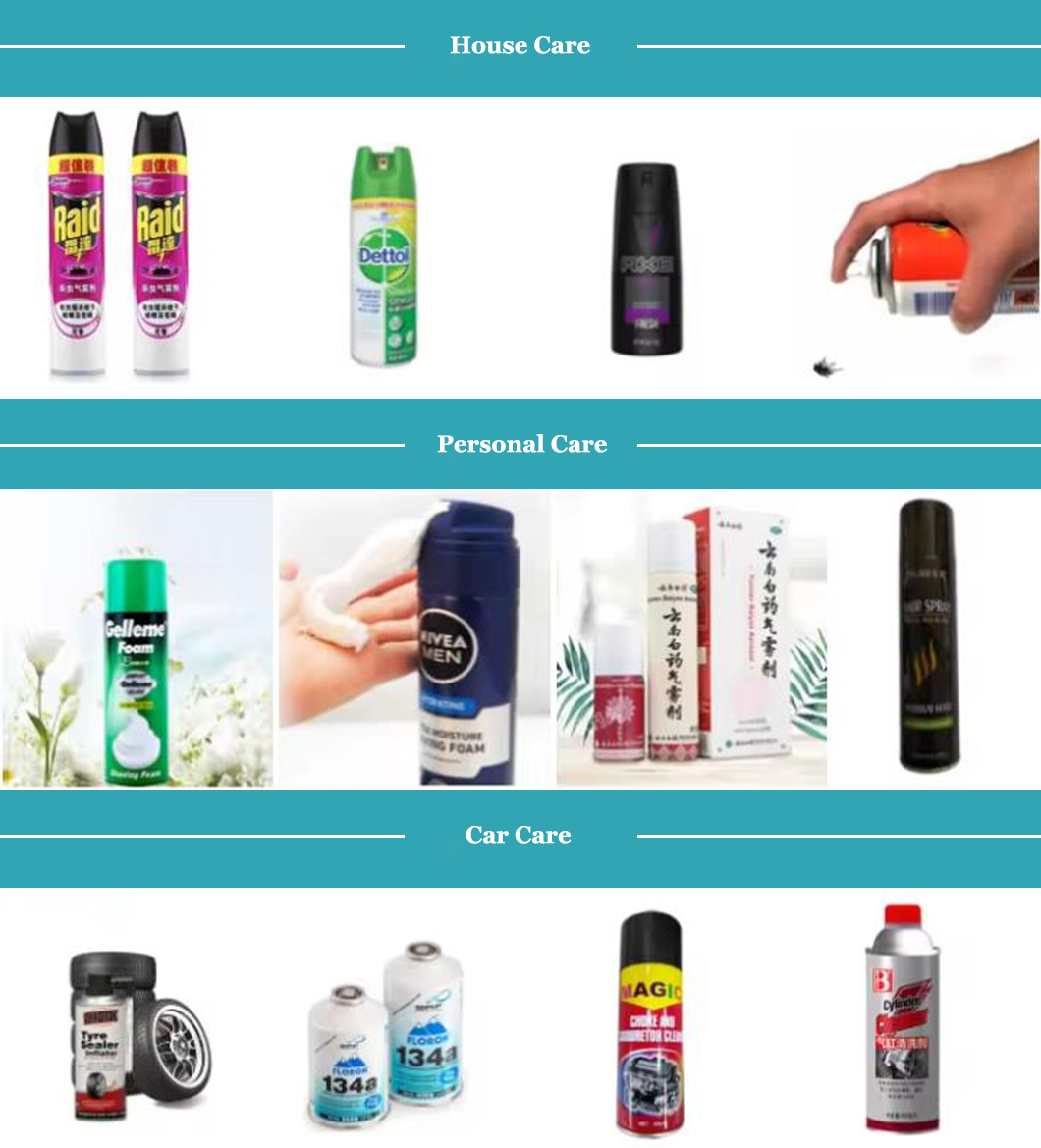

Products Show:

Food: Aerosol cans are also available for whipped cream, frosting,chocolate, and coffee powders, as well as cooking oils.

Home: Pesticides, dust and spot removers, and air fresheners are among the commonplace items that can be in aerosols.

Pharmaceutical: Nasal sprays, saline solutions, multi-dose injectables,and topical aerosols are filled using aerosol filling equipment in the pharmaceutical industry.

Cosmetics and Personal Care: Sunscreens, shaving gels, foams,deodorants, body sprays, and perfumes are just some of the cosmetics products that use aerosol filling machines.

Industrial: Products for auto maintenance and painting are two examples of industrial uses for these devices.

How to selecting an Aerosol Filling Machine?

When choosing an aerosol filling machine, consider factors such as:

1.Production Volume: Match the machine's capacity to your production needs.

2.Product Specifications: Ensure the machine can handle your specific formulation and propellant.

3.Automation Level: Decide between semi-automatic and fully automatic based on your budget and production scale.

4.Quality and Reliability: Choose a reputable manufacturer to ensure machine reliability and support.

Our Service:

Our service capabilities quarantees optima efficiency:

We offer for remote assistance, on-site service, training, and machine audits. Access to experienced OEM Parts Department and Modernization team.

We intimately know your machine, resulting in less downtime, extended equipment life, andincreased ROI.

After-sales service:

1.Two years warranty .

2.Engineers available to service machinery overseas.

3.Professional sellers are always at your service.

4.We can provide customer factory plan,layout, installation,training and so on.

5.We guarantee the machine 100% easy use because we would take video for every machine for test.