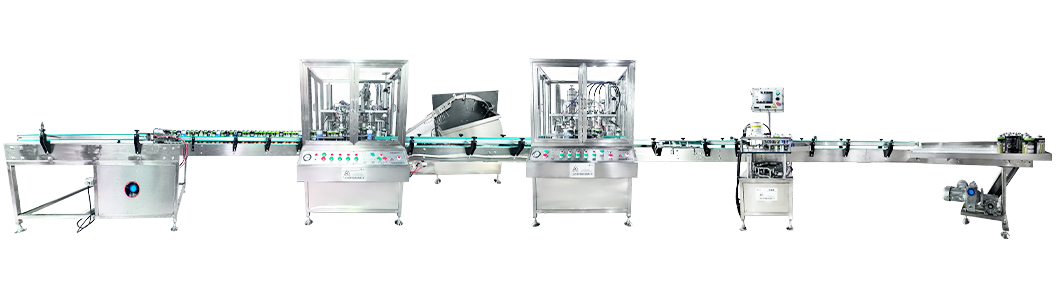

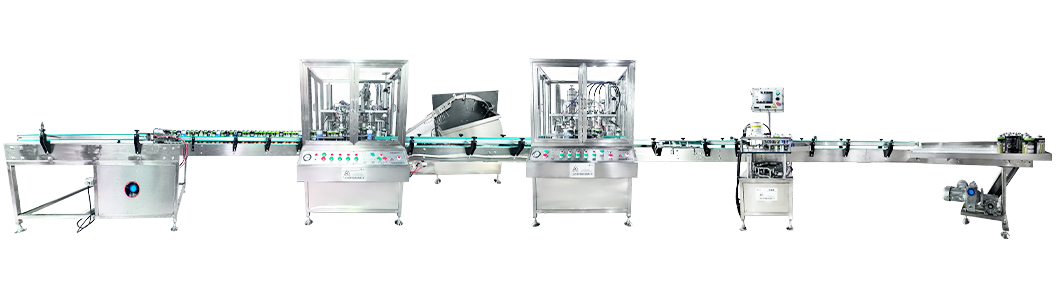

Operation Process:

Aerosol can feeding table --- Automatic conveyor cans input --- Can detector head & Automatic liquid filling & Automatic insert valve & Correcting valve --- Automatic air inflating and crimping --- Weight checking----Worktable

Technical Parameters:

Technical Parameter | Description |

Filling capacity (cans/min) | 60-70 |

Liquid filling volume (ml) | 10-1200( can be customized) |

Gas filling volume (ml) | 10-1200( can be customized) |

Filling heads | 4 heads |

Filling accuracy | ≤±1% |

Applicable cans diameter (mm) | 35 - 70( can be customized) |

Applicable cans height (mm) | 80 - 300( can be customized) |

Applicable valve | 1 inch |

Working pressure (Mpa) | 0.6 - 0.8 |

Max gas consumption (m3/min) | 5 |

Power (KW) | 7.5 |

Dimension (LWH) mm | 22000*3500*2000 |

Material | SS304 ( some parts can be SS316) |

Warranty | 1 year |

Key Selling Points | High speed fully automatic high production |

Maintenance Requirements | Recommended maintenance procedures and schedules |

Certifications and Standards | CE&ISO9001 |

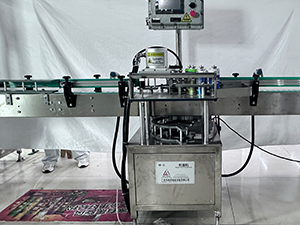

Detailed Images:

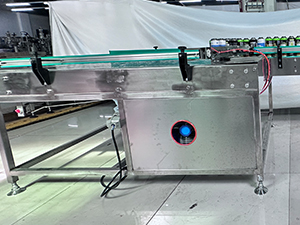

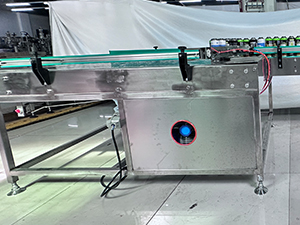

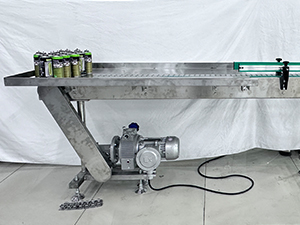

Auto Can Feeding Machine:

It consists of 13 flat-roofed conveyor belts, an explosion-proof motor and relevant control parts. It can feed the cans to the next station automatically with changeable speed availability.

Features:

Completely pneumatic driven parts make sure safe operation.

Necessary configuration and optional parts are available.

Suitable for customers who have demand for mass production of aerosol products.

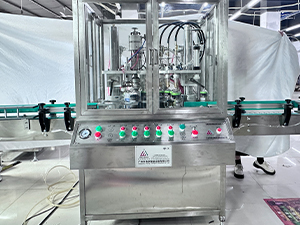

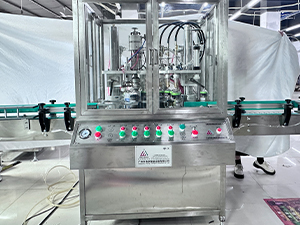

Liquid Filling Machine:

It is designed at one working table. It consists of 4 liquid filling heads, can detector head, insert valve and correcting valve. It features no can, no working. For the correcting valve, it works after the valves are placed and it will stop work if there is a missing valve.

Features:

Completely pneumatic driven parts make sure safe operation.

Users can choose how many liquid filling heads to work.

No can no filling.

Stable performance to make sure achieve high productivity.

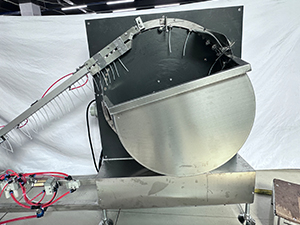

Insert Valve:

Completely pneumatic driven parts make sure safe operation.

Flexible valve insert .

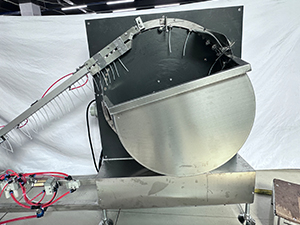

Crimping and Gas Filling Machine:

Features:

Completely pneumatic driven parts make sure safe operation.

The number of gas filling heads and dosage of gas filling volume can be customized.

Vide variety of propellant applicable: Compressed air, LPG, DME, CFC, Nitrogen, Carbon dioxide, etc.

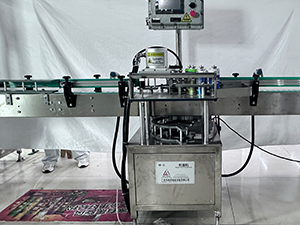

Weight Checking Machine:

Instant weight display, parameter adjustment is visual and convenient, also with simple weight calibration and adjustment function for various demand of check speed.

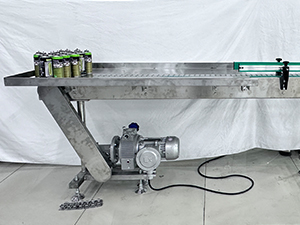

Packing Table:

This Accumulating Table is the final machine of QGJ70 Aerosol Filling Machine. It takes in completed cans and allows operators to gather and pack them.

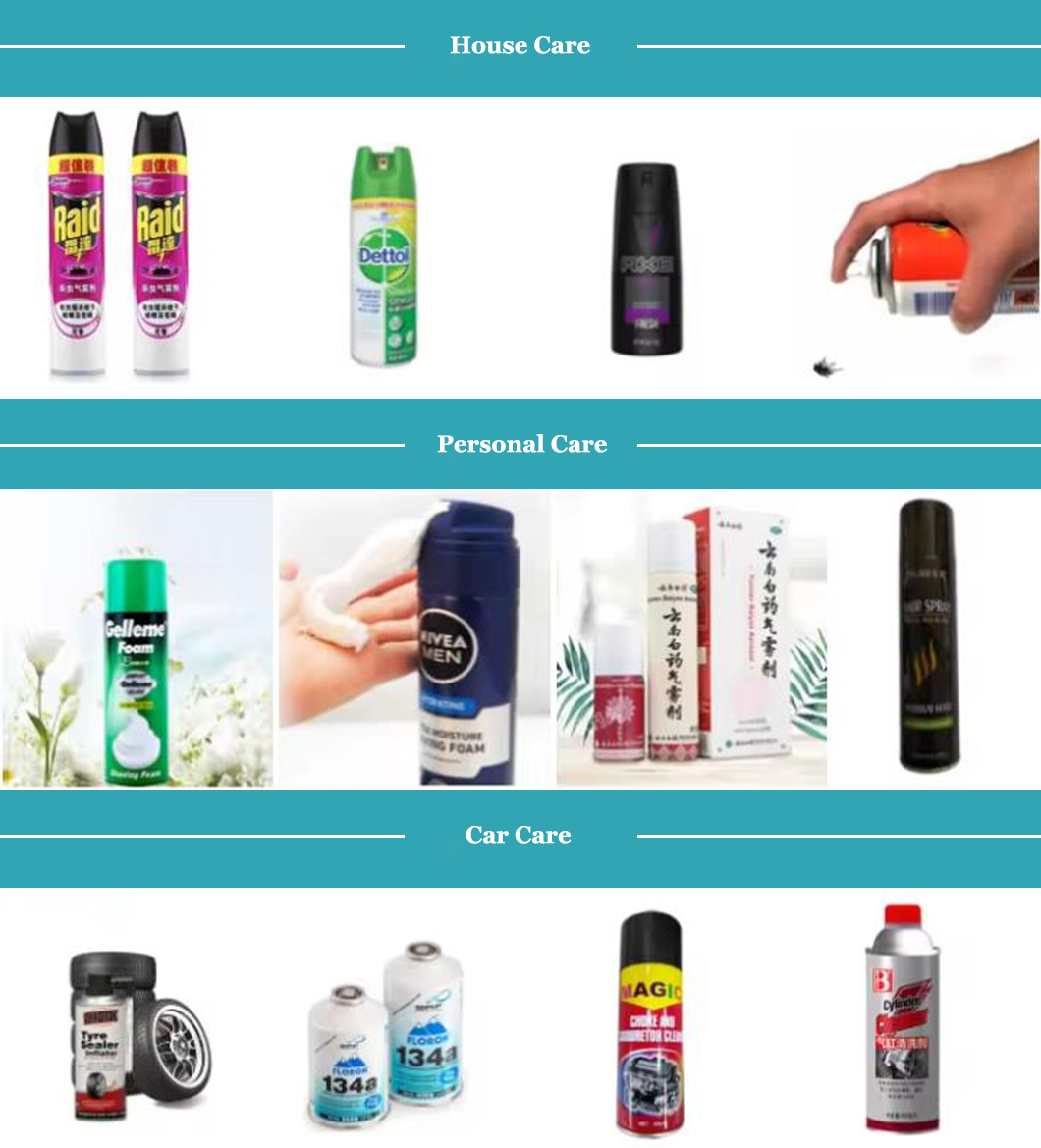

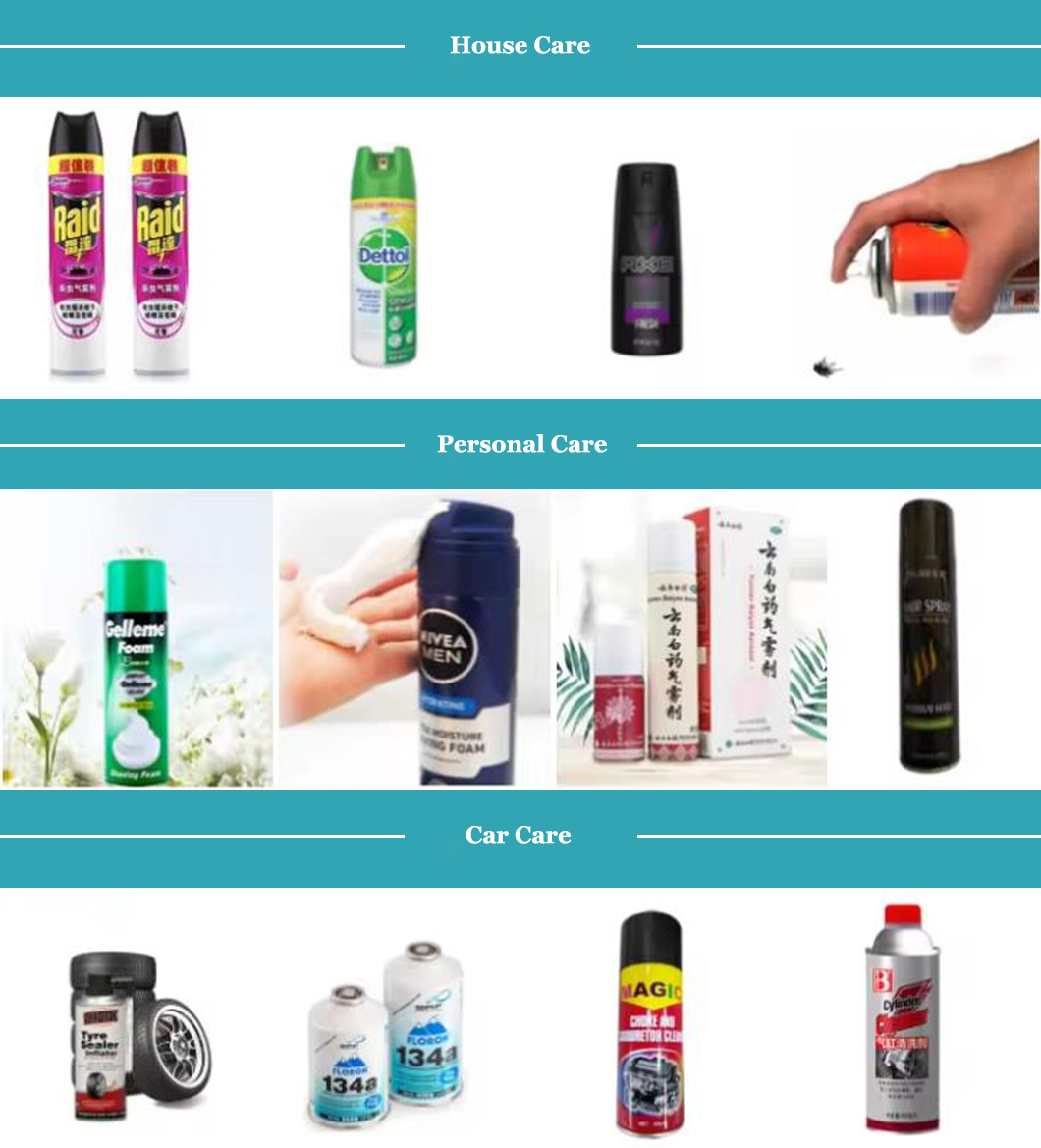

Products Show:

Food: Whipped cream, frosting, chocolate, and coffee powders, as well as cooking oils can also be available in aerosol cans.

Home: Among the commonplace items that can be in aerosols are pesticides, dust and spot removers, and air fresheners.

Pharmaceutical: In the pharmaceutical industry, nasal sprays, saline solutions, multi-dose injectables, and topical aerosols are filled by aerosol filling equipment.

Cosmetics and Personal Care: Some of the cosmetics products that use aerosol filling machines are sunscreens, shaving gels, foams, deodorants, body sprays, and perfumes.

Industrial: Auto maintenance and painting products are two examples of industrial uses of these devices.

How to selecting an Aerosol Filling Machine?

1.Production Volume: The capacity of the machine should be in line with your production requirements.

2.Product Specifications: Make sure the machine is capable of handling your specific formulation and propellant.

3.Automation Level: Based on your budget and production scale, determine whether to choose a semi-automatic or fully automatic machine.

4.Quality and Reliability: Select a reputable manufacturer to guarantee machine reliability and support.

Our Service:

Our service capabilities ensure optimal efficiency:

We provide remote assistance, on-site service, training, and machine audits. You have access to an experienced OEM Parts Department and Modernization team. We have an in-depth understanding of your machine, leading to less downtime, a longer equipment lifespan, and increased return on investment.

After-sales service:

1. There is a two-year warranty.

2. Engineers are available to service machinery overseas.

3. Professional sellers are always ready to serve you.

4. We can offer customer factory plans, layouts, installations, training, and more.

5. We guarantee that the machine is 100% easy to use as we would take a video of each machine for testing.