2024.6.5update

Product Advantages:

1. Accuracy: Achieves unparalleled fill weight precision, ensuring regulatory compliance and customer satisfaction with consistent product performance.

2. Scalability: Facilitates easy expansion or adjustment of production capacity to meet fluctuating market demands or introduce new product lines.

3. Traceability: Integrates seamlessly with existing track-and-trace systems, enabling thorough documentation and quick response to potential recalls or quality issues.

4. Environmental Sustainability: Minimizes propellant loss and waste generation, contributing to reduced environmental impact and enhanced corporate sustainability efforts.

5. Maintenance & Upgradability: Features modular design and accessible components for simplified maintenance, with potential for future upgrades to accommodate technological advancements or process innovations.

ance and regulatory conformity.

Technical Parameters:

Technical Parameter | Description |

Filling capacity (cans/min) | 60-70 |

Liquid filling volume (ml) | 10-1200( can be customized) |

Gas filling volume (ml) | 10-1200( can be customized) |

Filling heads | 4 heads |

Filling accuracy | ≤±1% |

Applicable cans diameter (mm) | 35 - 70( can be customized) |

Applicable cans height (mm) | 80 - 300( can be customized) |

Applicable valve | 1 inch |

Working pressure (Mpa) | 0.6 - 0.8 |

Max gas consumption (m3/min) | 5 |

Power (KW) | 7.5 |

Dimension (LWH) mm | 22000*3500*2000 |

Material | SS304 ( some parts can be SS316) |

Warranty | 1 year |

Key Selling Points | High speed fully automatic high production |

Maintenance Requirements | Recommended maintenance procedures and schedules |

Certifications and Standards | CE&ISO9001 |

Product Uses:

1. Cosmetics & Hygiene: Expedites manufacture of fragrances, deodorants, emollients, preserving meticulous dose control and asepsis.

2. Household & Cleaning: Efficiently packages air fresheners, cleaning agents, insect repellents, ensuring homogeneous spray distribution and efficacy.

3. Pharma & Medical: Vital for encapsulating inhalers, ointments, disinfectants; upholds exact dosing, sterility to protect patient health.

4. Food & Drink: Food-grade systems encapsulate whipped toppings, cooking oils, flavor enhancers; adheres to safety standards, preserves taste integrity.

5. Automotive & Engineering: Dispenses lubricants, degreasers, anti-corrosives; guarantees precise amounts, product stability for optimal functionality.

6. Agri & Horticulture: Contain pesticides, fungicides, growth stimulants; fosters uniform application, supports crop management.

7. Arts & Crafts: Fills art sprays, adhesives, texturizing mediums; ensures uniform viscosity, color consistency, and precision delivery for professional results.

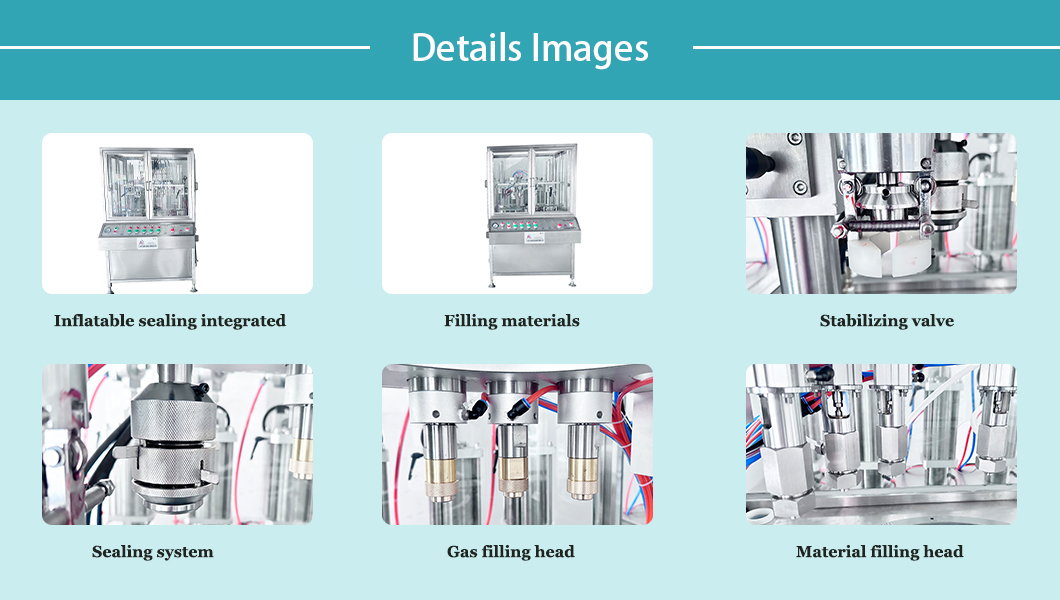

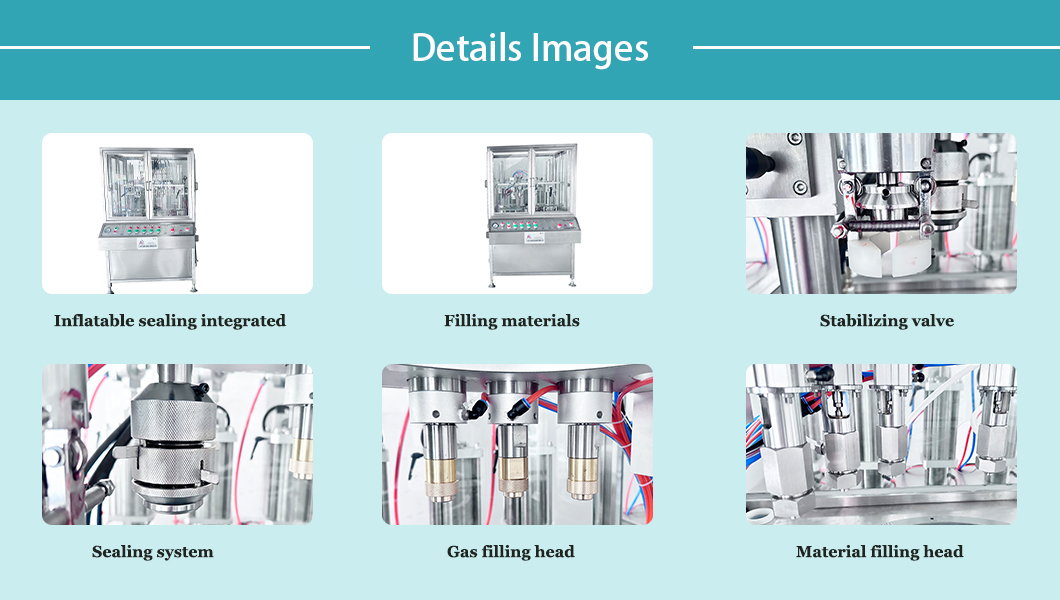

Detailed Images:

FAQ:

1. How does an automatic aerosol filler elevate product quality?

Through consistent delivery of precise quantities, maintenance of optimal internal pressures, and secure sealing, it enhances product consistency, performance, and shelf life.

2. Can an automatic aerosol filler handle diverse product types simultaneously?

Yes, its quick-change features and versatile filling heads enable seamless transitions between distinct formulations and packaging configurations.

3. How does the machinery maintain hygiene during filling operations?

Employing stainless steel construction, Clean-in-Place (CIP) systems, and HEPA air filtration, it minimizes contamination risks and rigorously conforms to sanitation standards.

4. What is the typical throughput rate of an automatic aerosol filler?

Depending on the model and configuration, these machines can fill anywhere from several hundred to thousands of cans per hour, offering adaptable production capacities.

5. Are automatic aerosol fillers customizable to address specific production needs?

Absolutely, they can be tailored with additional functionalities like labeling, coding, or inspection modules to suit individual client requirements and seamlessly integrate into existing production lines.