|

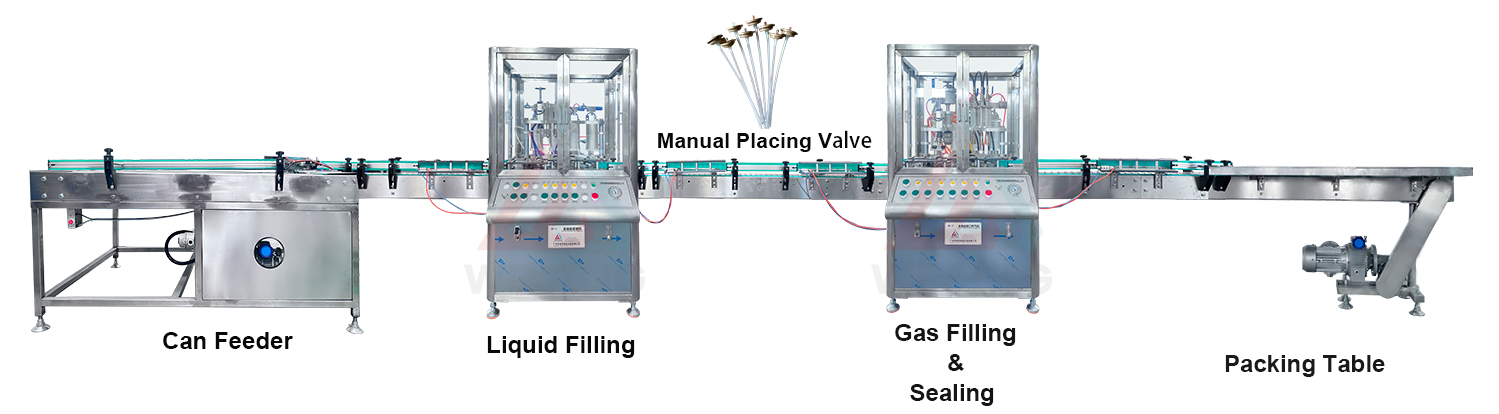

Product Introduction

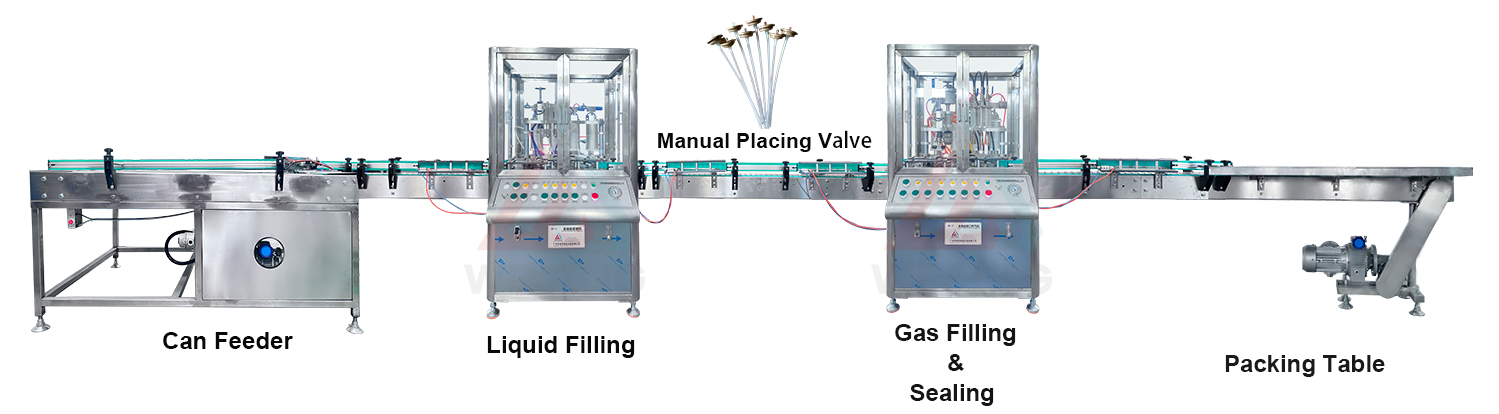

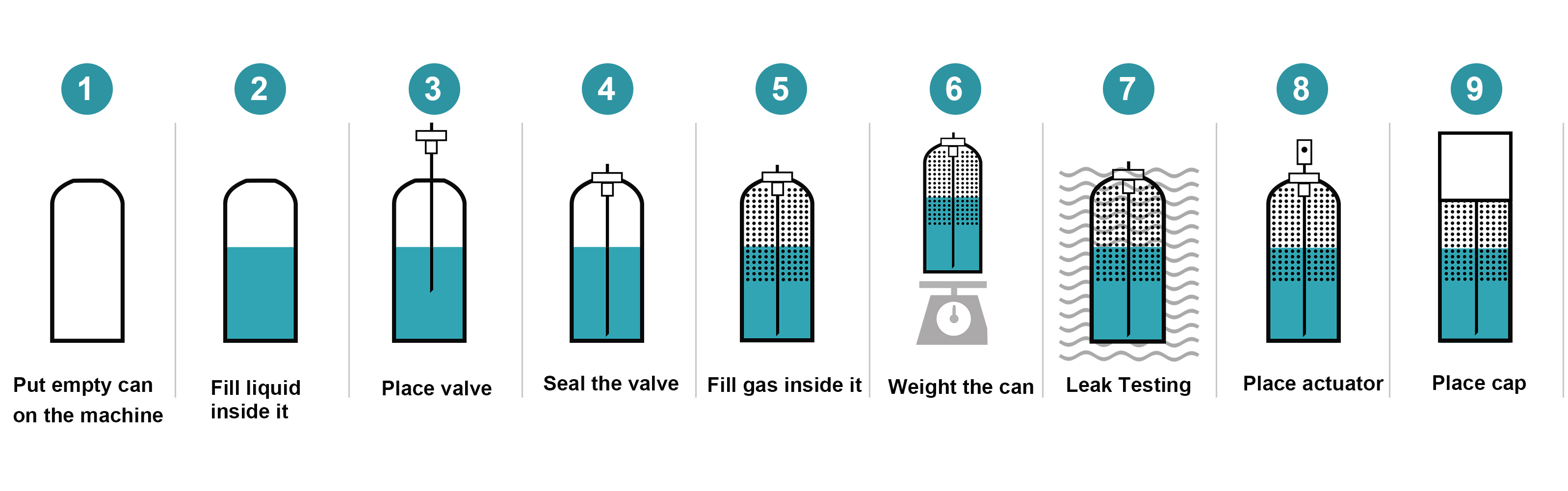

This Automatic aerosol filling production line is composed of ,index type four heads liquid filling machine, index type crimping head & four heads gas filling machine, conveyor, .it also could equipped with automatic weighing checker, , automatic printer, automatic actuator presser, automatic cap presser automatic water-bath leakage tester

|

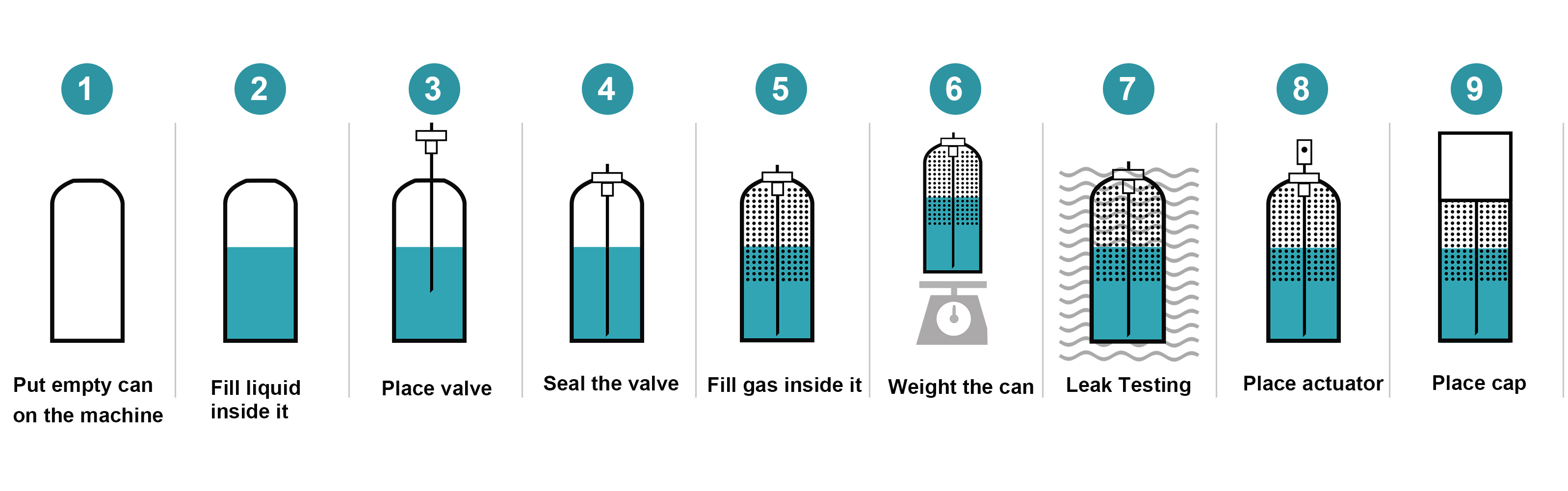

Process Flow

|

Parameter

NO. | Name | Description |

1 | Filling capacity | 60-70cans/min |

2 | Liquid filling volume | 10-1200 ml ( can be customized) |

3 | Gas filling volume | 10-1200ml( can be customized) |

4 | Filling heads | 4 liquid heads & 4 gas filling head |

5 | Filling accuracy | ≤±1% |

6 | Applicable cans diameter | 35 - 70mm( can be customized) |

7 | Applicable cans height (mm) | 80 - 300mm( can be customized) |

8 | Applicable valve | 1 inch |

9 | Working pressure | 0.6 - 0.8Mpa |

10 | Max gas consumption | 5m3/min |

11 | Material | SS304 ( some parts can be SS316) |

|

Feature

1) This machine is composed of a bottle arranging workbench, a fully automatic filling machine, an automatic valve loading machine, an automatic sealing and gas filling machine, an automatic weighing and rejection machine, an automatic nozzle loading machine, an automatic large cap loading machine, and a collection platform.

2) The liquid filling system adopts a piston working principle and is suitable for various viscous liquids. It is all made of 304 stainless steel. It has 4 liquid filling heads and can freely switch between point operation and automatic modes.

3) The sealing head adopts a guiding sealing method. If the sealing quality is not high, the machine will automatically stop. The inflation head adopts a guiding inflation method, which is accurate, efficient and consumes very little air.

4) The conveying system can be designed in a U-shaped rotary structure to save space.

5) This machine features high production efficiency, safety and reliability, simple operation and convenient maintenance.

|

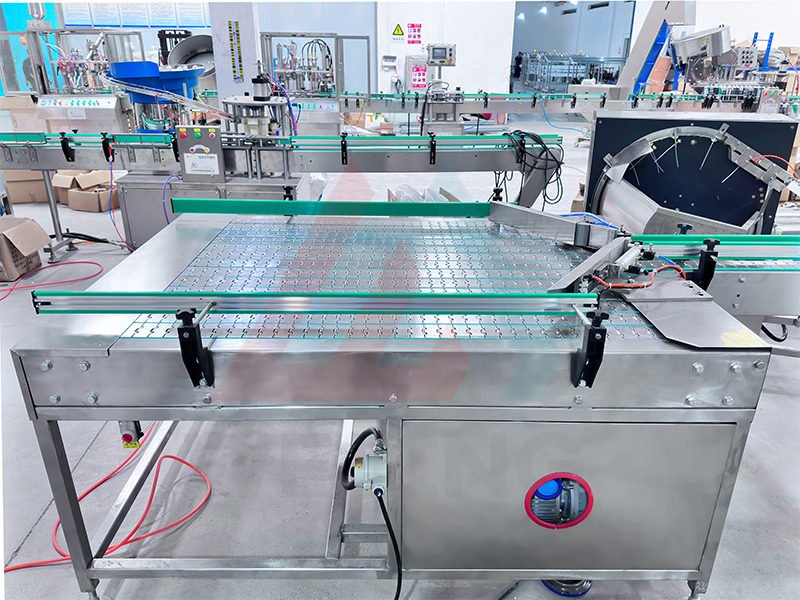

Machine Detail

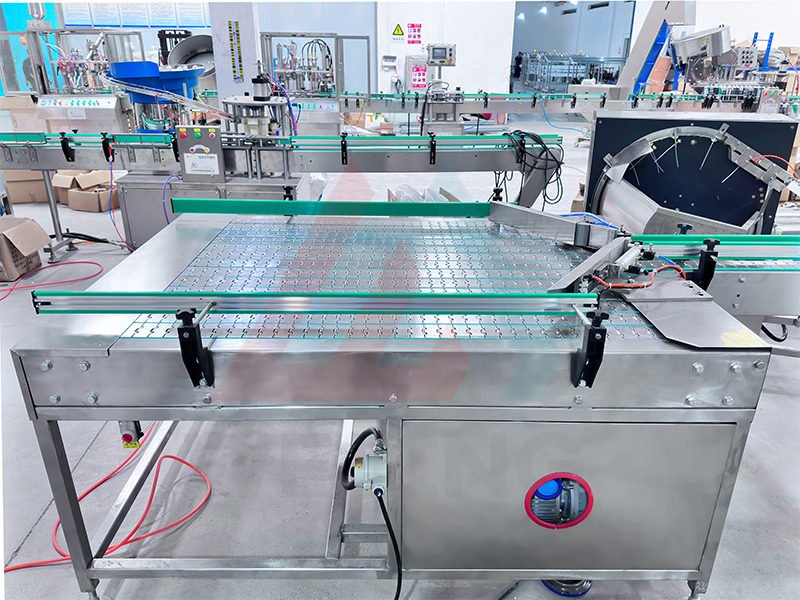

1.Empty cans feeder

Continuously transferring cans from the arranger to other equipment for automatic conveying.

The conveying speed is adjusted by adjusting the speed difference (e.g. speed differential) of the motors to meet different production requirements.

2.Filling and Valve Inserted Machine

1.Can detecter head. No can,No working

2.4 liquid filling heads

Speed:60-70 cans/min

Filling volume:10-1200 ml ( can be customized)

3.Gas filling machine

1.Valve centralized

2. Crimping head

3. 4 Gas filling heads

4. Each part can be controlled independently

Speed:60-70 cans/min

Filling volume:10-1200 ml ( can be customized)

|

Application

Suitable for filling paint sprays, deodorant sprays, lubricant sprays, hair styling sprays, insecticide aerosols, air fresheners, and cleaning and care sprays.

|

Product Description

Lubricant aerosol filling line

Wooden case protection

Transpotation

|

Product Description

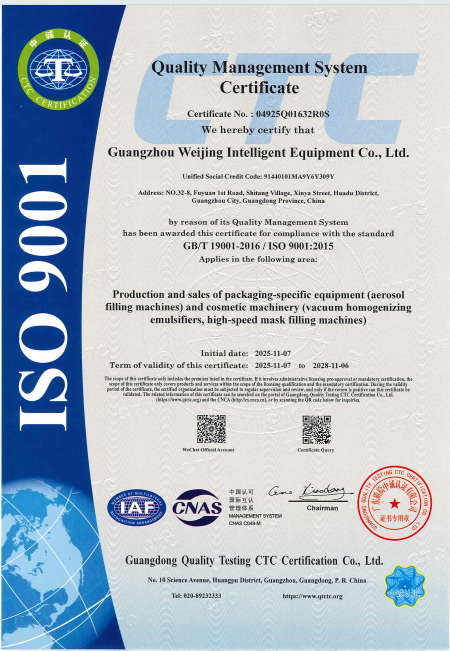

ISO9001

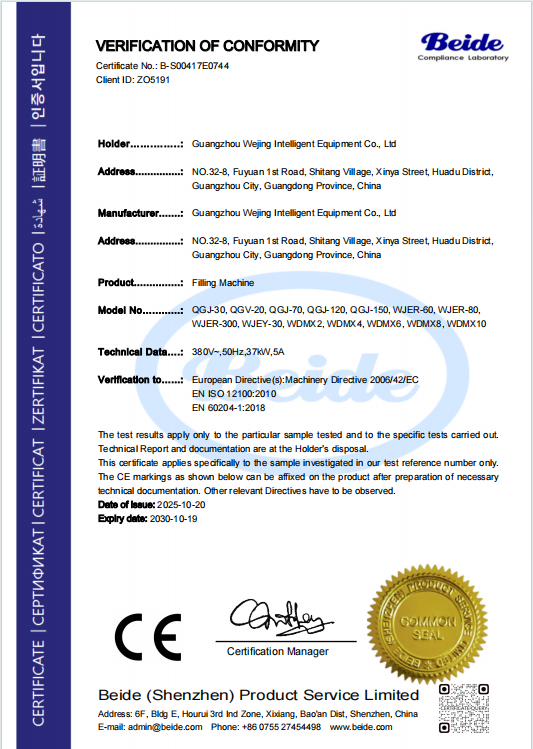

CE