Product Advantage:

The Stainless Steel 304 And 316 Vacuum Mixer with Homogenizer Tank offers several key advantages. It is constructed with high-quality stainless steel, ensuring durability and resistance to corrosion. The vacuum mixer creates a controlled environment, preventing air incorporation and bubble formation during mixing. The homogenizer tank enhances mixing efficiency, achieving a uniform and consistent blend. With its precise control system, the mixer allows for accurate temperature and speed regulation. These features make it ideal for applications in the chemical, pharmaceutical, food, and cosmetic industries.

Technical Parameters:

| Type | Volume(L)

| Power of vaccum pump(kw) | Hydraulic pump

(kw) | Lifting height of vessel cover (mm) | Dimension(L*W*H)

(mm)

| Weight(kg) |

WJ-TP100

| 100

| 3

| 1.1

| 800

| 2450*1500*2040

| 2500 |

| WJ-TP700 | 700 | 4 | 1.5 | 1000 | 4530*3800*2480

| 3000 |

| WJ-TP1300 | 1300 | 7.5 | 2.2 | 1000 | 1920*3910*3200

| 4500 |

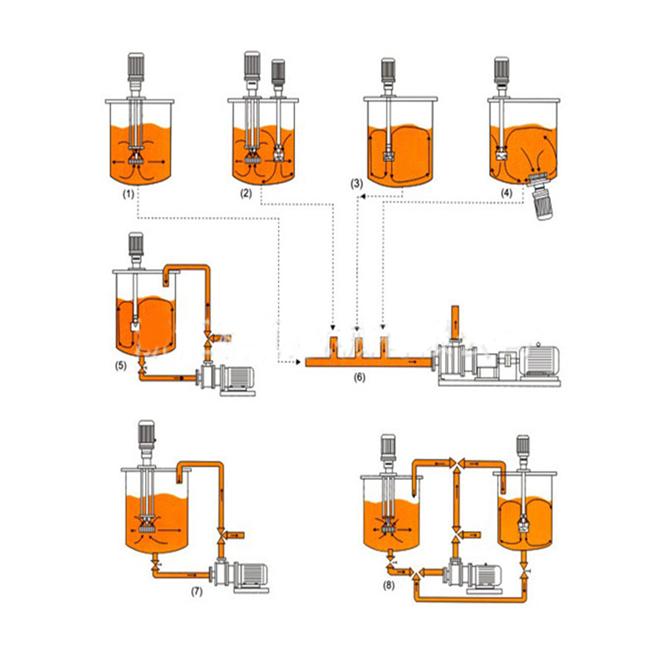

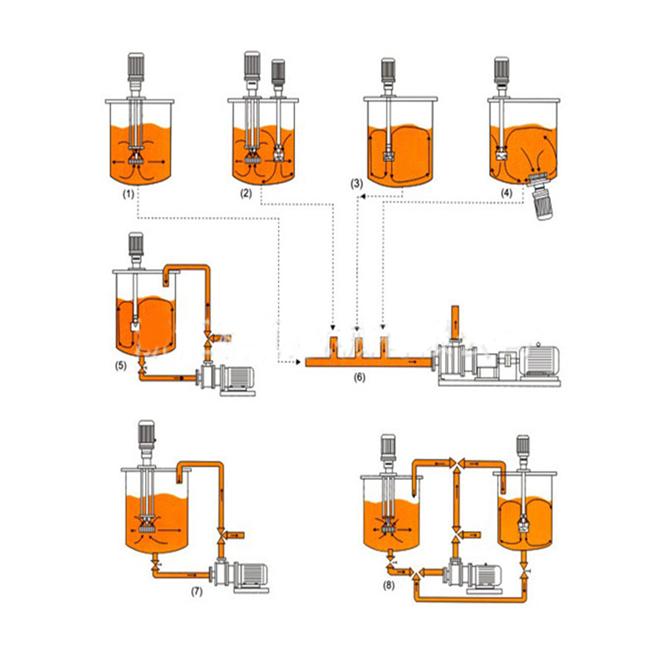

Product Uses:

304 and 316 stainless steel vacuum mixers and homogenizer tanks can be applied in various industries. It is widely used in the chemical industry for mixing and blending chemicals. In the pharmaceutical industry, it contributes to the production of suspensions and lotion. The food industry uses it to mix and homogenize ingredients. In addition, it is also used in the cosmetics industry to manufacture uniform formulas. Its vacuum mixing ability makes it suitable for handling sensitive materials, ensuring product quality and consistency.

Using Intruduction :

1. Prepare the ingredients and load them into the homogenizer tank.

2. Ensure a tight seal by closing the lid.

3. Connect the vacuum pump and turn it on to create a vacuum environment.

4. Adjust the mixing speed and time as per your formula requirements.

5. Start the mixer and monitor the process until the desired consistency is achieved.

FAQ:

1. What are the materials used in the construction of this mixer?

This mixer is constructed using high-quality stainless steel 304 or 316, ensuring durability and resistance to corrosion.

2. What is the function of the homogenizer tank?

The homogenizer tank helps to achieve a uniform and consistent mixture by breaking down particles and reducing viscosity.

3. Can this mixer handle vacuum mixing?

Yes, this mixer is designed to handle vacuum mixing, creating a controlled environment to prevent air incorporation and bubble formation.

4. How does the mixer ensure precise temperature control?

The mixer features a precise control system that allows for accurate temperature regulation during the mixing process.

5. Is the mixer easy to clean and maintain?

Yes, the mixer is designed for easy cleaning and maintenance, with accessible components and simple disassembly procedures.