2024.6.6 update

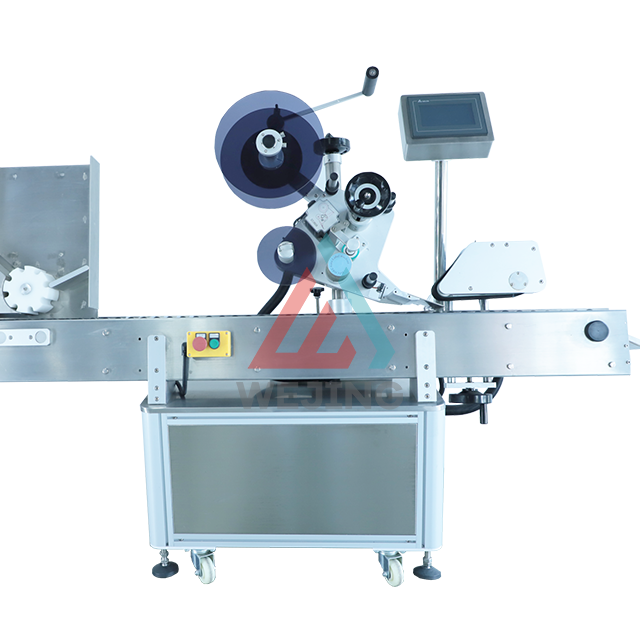

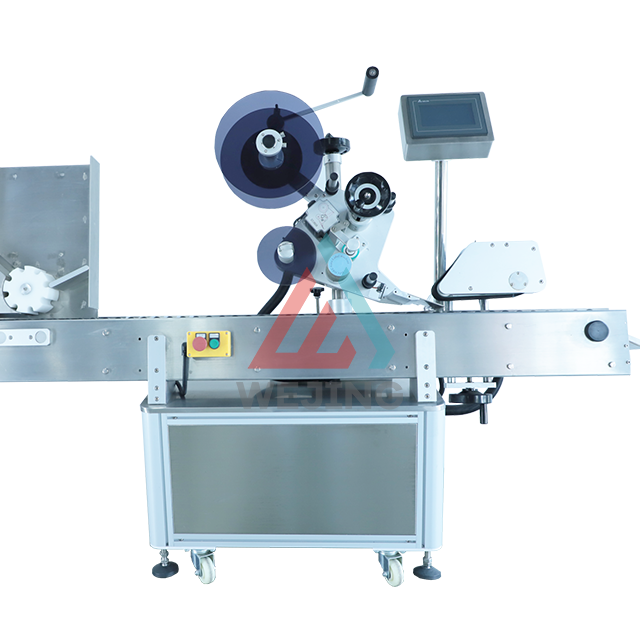

Equipment characteristics:

1. High labeling accuracy: The ampoule labeling machine adopts advanced labeling technology to ensure that the labels are accurately attached to the ampoules, without deviation or wrinkles.

2. High efficiency: This machine can automatically complete the labeling process of a large number of ampoules, which improves work efficiency and saves labor costs.

3. Easy to operate: The operation interface of the ampoule labeling machine is simple and intuitive, easy to operate and maintain.

4. Flexible adjustment: This machine can adjust the labeling position and speed according to different ampoule sizes and labeling requirements.

5. Safety and reliability: The ampoule labeling machine is made of high-quality materials and components, and has passed strict quality testing to ensure safe and reliable operation.

Technical Parameters:

Labeling speed | 0-100P/min (depending on product and label size) |

Labeling accuracy | ± 1mm (excluding errors such as product labels) |

Applicable product size | Diameter 15-35mm; Height 30-100mm; |

Applicable label range | Length 10-100mm, base paper width 10-100mm |

Maximum label supply | Within an outer diameter of 300 and an inner diameter of 76mm |

Environmental temperature/humidity | 0-50℃/15-85% |

Voltage | AC220V/50HZ |

Dimension | 2200*1000*1700mm(L*W*H) |

Weight | 190kg |

Product application:

1. Pharmaceutical industry: The ampoule labeling machine is widely used in the labeling of various liquid drugs, such as injections, syrups, and eye drops.

2. Cosmetic industry: This machine can be used to label various liquid cosmetics, such as essence, lotion, and foundation.

3. Food industry: The ampoule labeling machine can be used to label various liquid foods, such as juice, milk, and honey.

4. Chemical industry: This machine can be used to label various liquid chemicals, such as reagents, adhesives, and coatings.

5. Daily chemical industry: The ampoule labeling machine can be used to label various liquid daily chemicals, such as detergents, shampoos, and lotions.

Product operation:

1. Adjustment of labeling position: The labeling position of the ampoule labeling machine can be adjusted according to the size and shape of the ampoule to ensure accurate labeling.

2. Adjustment of labeling speed: The labeling speed of the ampoule labeling machine can be adjusted according to the production requirements to meet the needs of different production lines.

3. Automatic feeding: The ampoule labeling machine can automatically feed the ampoules, which saves labor and improves production efficiency.

4. Automatic labeling: This machine can automatically label the ampoules, which ensures the accuracy and consistency of the labeling.

5. Automatic rejection: If the ampoule labeling machine detects that the labeling is not correct or the ampoule is defective, it can automatically reject it to ensure the quality of the product.

Maintenance methods:

1. Use a cleaning agent and a clean cloth to clean the mechanical parts.

2. Avoid getting water and cleaning agent on the electronic components.

3. Check for sundries before starting the machine every day.

4. Observe the power supply conditions and avoid objects falling into the machine.

5. Do not use the labeling machine in a humid, dusty, or polluted environment.