Choosing the right bag-on-valve supplier is very important. It affects your product's safety and if it follows the rules. It also helps your business grow. You should look at important things like quality and certifications. You also need a supplier with strong production power. Bag on valve technology makes products last longer. It lets you spray from any angle. It also helps your products meet tough environmental rules. This technology keeps the inside clean and cuts down on waste. People like this because they want safe and green packaging. Your supplier's new ideas and help matter a lot. They affect how well your products work and how easy your business runs.

Bag-on-valve systems use air or nitrogen. This makes them safer and better for the planet than old ways.

Key Takeaways

Bag-on-valve technology keeps products clean and safe. It makes spraying easy from any angle. It also cuts down on waste and helps the environment.

Picking a supplier with good quality checks is important. They should have certifications and strong production skills. This keeps your products safe and helps your business grow.

Good suppliers let you customize your packaging. This makes your packaging special. It helps your brand get noticed in the market.

New ideas and caring for the planet make bag-on-valve systems better. They help products work well and lower harm to the environment.

Top suppliers give global support and reliable tools. This helps your business work well and meet customer needs everywhere.

Bag on Valve Technology

What Is Bag-on-Valve?

Bag-on-valve technology is used in lots of industries. This system keeps your product clean and safe. It uses a special bag-on-valve setup. The product stays away from the propellant. This means you get a cleaner spray each time.

Bag-on-valve technology helps you use almost all your product. You can spray it from any direction, even upside down.

Here's how the bag-on-valve system works:

The product is inside a foil bag with many layers. The bag is attached to the valve.

Air or nitrogen fills the space between the bag and the can. This is the propellant.

When you press the actuator, the gas pushes the bag. The product comes out through the valve.

You can spray in every direction and waste very little.

The system uses gases that are good for the environment and materials you can recycle.

Component | Description/Material | Function/Working Principle |

Bag on Valve | Multi-layer laminated foil bag (3-4 layers) | Holds the product; welded to the valve; flexible to be squeezed by external pressure |

Lined Can | Aluminum or tin with coatings | Contains the bag and propellant; protects product; material choice affects cost and performance |

Actuator/Cap | Plastic or compatible material | User interface to press and release product through valve and nozzle |

Valve | Female or male type with stem construction | Controls product release; female valves allow faster filling but cost more |

Propellant | Compressed air or nitrogen | Fills space between bag and can; applies external pressure to squeeze bag and dispense product |

Bag-on-valve technology works for many things. You see it in food sprays, medicine, glue, cleaners, and personal care. It keeps food fresh and medicine safe from germs. It also helps cleaners and lotions come out smoothly. You get safe and clean use every time.

Bag-on-valve technology is safe, works well, and is good for the planet. You can use it for both liquids and thick stuff. It gives a steady spray and keeps your product clean. It also helps with green packaging.

Why Supplier Choice Matters

Product Quality

You need a bag-on-valve supplier who cares about quality. The right supplier uses special steps to keep products safe. They close and seal each valve tightly to stop leaks. This keeps the product inside safe. The product stays away from the propellant, so it stays clean. Every can gets tested in water to find leaks before shipping. The actuator and cap are put on to make sure the spray works right.

Top suppliers use machines to crimp and seal valves. These machines make sure every valve is tight. They check the weight and pressure during filling. This way, every can has the right amount inside. They watch for problems as they fill the cans. This helps keep your products safe and stops big mistakes.

Good quality means your product lasts longer and is safer. It also makes your brand stronger.

Big suppliers like Aptar Group and WEJING use their own machines. They work with other companies to fill cans. They bring new ideas and check quality closely. You get a bag-on-valve system that sprays well, works upside down, and wastes almost nothing. This level of care protects your money and keeps customers happy.

Production Efficiency

Production efficiency affects your costs and profits. The best suppliers use machines instead of people to fill cans. This saves money and makes products faster. You get your products sooner and pay less.

Modern machines break down less and make fewer mistakes. They use less material and make less waste. You get your products faster and on time. When your supplier buys new machines, you get a big advantage. You can meet orders, save money, and make more profit.

Benefit | Impact on Your Business |

Automated valve lines | Faster production, lower cost |

Real-time monitoring | Fewer errors, better safety |

Less waste | Higher ROI, greener operation |

A good supplier gives you both quality and speed. You get safe, strong bag-on-valve products that help your business grow.

Key Supplier Criteria

Picking the best bag-on-valve supplier means looking at a few important things. You want your products to be safe and work well. You also want them to be special in the market. Good suppliers help you by having strong certificates, letting you change things, making lots of products, coming up with new ideas, caring about the planet, and helping you in many places.

Certifications & Compliance

Certificates show a supplier follows tough world rules. You need proof that every valve and bag-on-valve system is safe. This helps your products get into new places without problems.

Suppliers should have:

FDA approval for food and medical use.

ISO 9001:2015 for quality checks.

CE marking for selling in Europe.

ASTM and EN for material and safety.

UL/FM for fire safety valves.

NACE for stopping rust.

Certification Type | Description | Relevance to Bag On Valve Suppliers |

ISO Certification | Quality management and product conformity | Required for global market access |

API Certification | Oil and gas valve standards | Needed for industrial applications |

ASTM Standards | Material and safety criteria | Ensures safe, reliable valves |

EN Standards | European valve standards | Mandatory for EU markets |

ASME Standards | High-pressure valve standards | For demanding environments |

UL/FM Approval | Fire protection system standards | For safety-critical uses |

CE Marking | EU health, safety, and environment | Required for European sales |

NACE Certification | Corrosion resistance | For harsh environments |

Tip: Always ask your supplier for their newest certificates. This keeps your business safe and makes customers trust you.

Customization Options

Customization lets you make packaging that fits your brand. Good suppliers give you many choices for bag-on-valve systems. You can pick bag sizes, valve types, and actuator styles. This helps your products look different and work better.

Common customization options include:

Bag sizes from small to big.

Special valve and bag shapes for easy use.

Features like leak stops and eco-friendly parts.

Pouches with special shapes, notches, and holes.

Matte or shiny looks for your brand.

Printing for logos and info.

Anti-UV for outdoor storage.

Many actuator and cap styles.

Works with many container shapes and tools.

These choices help your brand stand out and make products easier to use. Customization also helps keep products safe and lets you spray in any direction.

Production Power

Production power means how many bag-on-valve units a supplier can make each day. You need a supplier who can make big orders and deliver fast. High production power means fewer delays and a better supply chain.

Shining Aluminum Packaging can make up to 300,000 bag-on-valve pieces every day. This helps big brands and fast-growing companies.

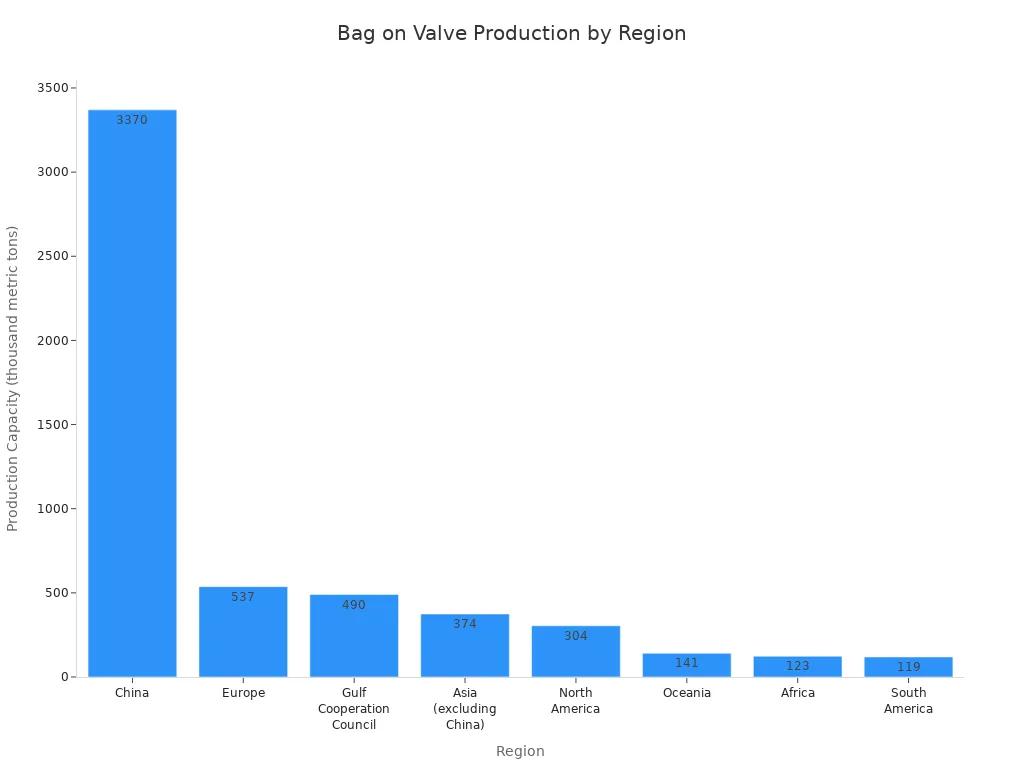

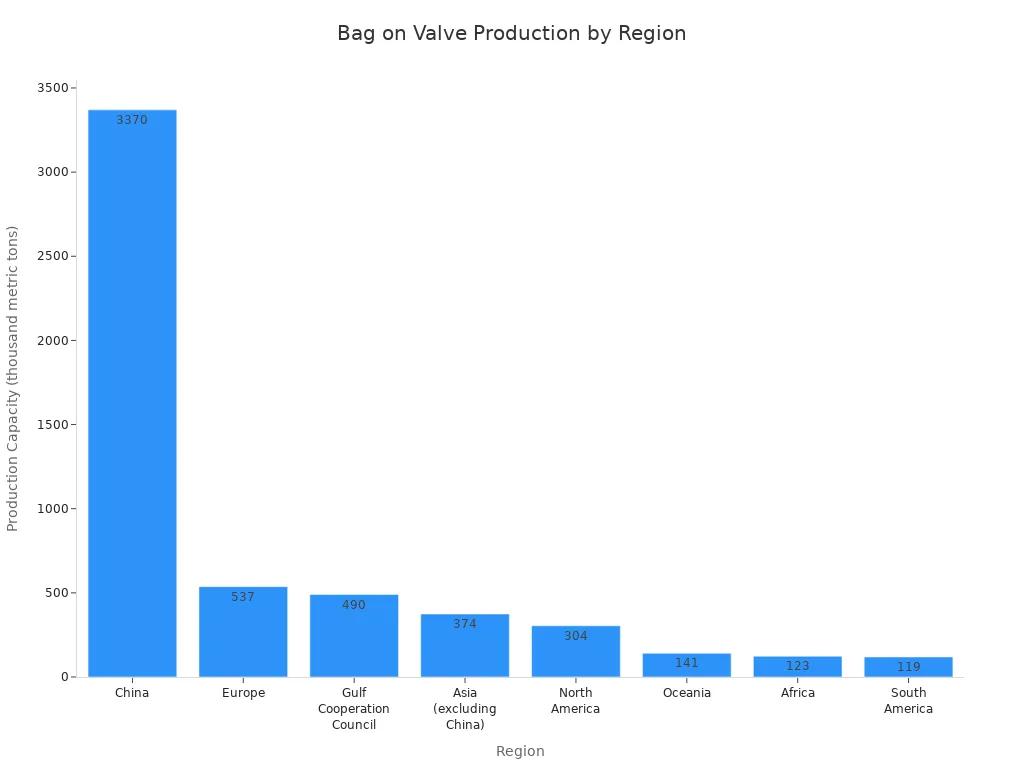

Region | Production Capacity (thousand metric tons) |

China | 3,370 |

Europe | 537 |

Gulf Cooperation Council | 490 |

Asia (excluding China) | 374 |

North America | 304 |

Oceania | 141 |

Africa | 123 |

South America | 119 |

Note: High production power helps you fill big orders and not run out.

Innovation & R&D

Innovation helps your products stay ahead of others. Good suppliers spend money on research to make better valves and bag-on-valve systems. They make new things like 360-degree spray and no-sediment use.

You get:

New actuator styles for better control.

Better bag materials for longer use.

Safety features to stop leaks.

Faster and better filling machines.

Suppliers who care about R&D help you make new products fast and follow trends.

Sustainability

Sustainability is very important for many companies now. Bag-on-valve technology helps the planet by using recyclable materials and safe gases like air or nitrogen. Suppliers make lighter cans and better valves to cut waste.

Key sustainability practices:

Use of recyclable and biodegradable packaging.

No bad gases or VOCs.

Up to 99% of the product gets used.

Longer shelf life means less spoilage.

Lighter packaging lowers shipping pollution.

Aspect | Traditional Aerosol | Eco-friendly Bag on Valve (BoV) |

Manufacturing Cost | Lower | Higher |

Consumer Price | Cheaper | Premium |

Product Wastage | High | Minimal |

Dispensing Angles | Limited | 360-degree capability |

Environmental Impact | Harmful propellants, hard to recycle | Air/nitrogen, recyclable, no CFCs |

Product Integrity | Mixed with propellant, shorter shelf life | Separated, longer shelf life |

Spray Performance | Uneven, noisy | Consistent, quiet |

Eco-friendly bag-on-valve systems may cost more, but they are safer, better for the planet, and work well.

Global Reach & Support

Global reach means you get help wherever you are. Top suppliers like Aptar Group, Coster, and Precision Valve Corporation have factories and teams all over the world. This means you get fast delivery, local help, and expert advice.

What you get from global suppliers:

Local labs for testing products.

Help with setting up and fixing equipment.

Faster delivery and lower shipping costs.

Same quality everywhere.

Help with launching products in many places at once.

Key Supply Chain Strategies | Description |

Strategic Manufacturing Networks | Sites in key regions for fast delivery |

Advanced Logistics Optimization | Efficient shipping and flexible response |

Digital Transformation & Connectivity | Real-time tracking and demand forecasting |

Sustainability & Regulatory Compliance | Meets global standards and reduces risk |

Product Flexibility & Customization | Adapts to customer needs quickly |

Good suppliers use smart tools to keep your supply chain strong and working well.

When you look at these important things, your business can do well. The right supplier gives you quality, choices, and help, so you can grow in a busy market.

Supplier Comparison

Leading Brands

You should pick suppliers that many people trust. These companies are leaders in the bag on valve industry. They always try to make better, safer, and greener products. They help you save money and get more value by giving you good valve solutions. Here are some top companies you should know:

Aptar Group

Amcor plc

Precision Valve Corporation

TUNAP Group

Lindal Group

Summit Packaging Systems

Gualapack S.p.A.

Coster Tecnologie Speciali S.p.A

Chicago Aerosol, LLC

Wipf Doypak

Farrag Packaging

KOH-I-NOOR Mladá Vožice a.s.

You can find these brands in lots of different businesses. They care about making packaging better for the planet. They also work hard to make new valve technology. Because they are well known, many big brands choose them as suppliers.

Strengths & Specialties

Every top supplier has something special to offer. Their valve systems keep your product safe and fresh. You can spray from any direction. They use air or nitrogen, which is cheaper and better for the earth. Their bag on valve technology works for beauty, food, and health. You can use it for things like deodorant, cooking spray, or medicine gel.

Bag Type | Unique Strengths and Specialties | Ideal Applications |

Poly R-Pac/Back Valve | Strong, easy to fill, can add handles and designs | Powdered chemicals, ice melt, fertilizers |

Poly Side Seal Open Mouth | Special pictures, handles, extra space, made for easy use | Sand, stone, fertilizer, halite |

Bottom Seal Open Mouth | Tough, stops leaks, can pick film, seals well | Salt pellets, fertilizer |

ADSL/Poly Valve Bags | Hard to break, closes by itself, fills fast, keeps stuff in, stacks well | Petrochemicals, minerals, fertilizers, salts |

Printed Poly Tubing | Reliable, few seals, easy for machines, can print designs | Petrochemicals, minerals, pelleted salt |

These trusted suppliers help many types of companies. For example, a medicine company started using bag on valve systems. Their products stayed safe and lasted longer. A personal care brand used a new valve to waste less and attract green buyers. These stories show how a good supplier helps you follow rules, save money, and get more value.

If you pick a manufacturer with lots of happy customers, you get valve solutions that really work for you.

Choose the Right Valve Bagging Equipment

Equipment Compatibility

Picking the right valve bagging equipment helps your business do well. The valve bag packer must fit your bag on valve system. If you pick the wrong one, you might get leaks or waste product. You want your valve bag fillers to work well with your bags and valves.

Here are some things to think about:

The valve bag packer should fill bags quickly and still do a good job.

The valve bag fillers must seal each bag tight so nothing leaks out.

The valve bag packer should work with your product's flow and feel.

The valve bag fillers need to fit your bag size and valve shape.

The valve bag packer should connect to your other machines.

The valve bag fillers must change for different bag sizes and valve types.

The right valve bag packer saves energy and cuts costs.

Look for safety stops and guards on your valve bagging equipment.

Easy controls help your team use the valve bag packer with less training.

A good valve bag packer keeps your work fast, safe, and clean. It also helps you stop costly problems.

Filling & Packing Needs

You need valve bag fillers that fit your special packing needs. The right valve bag packer lets you control speed, accuracy, and safety. Valve bag fillers use different ways to fill bags, like gravity, air, impeller, or auger. Each way works best for certain products and bags.

Valve bag fillers that match your product and bag will:

Stop spills and dust.

Keep bags closed and clean.

Keep production moving fast.

Let you change bag sizes or valve types easily.

A good valve bag packer also fits your space and budget. You want valve bagging equipment that grows with your business. Top suppliers help with setup, care, and fixing problems. They give training, spare parts, and remote help to keep your valve bag fillers working.

Service Type | What You Get |

Installation | Experts set up and test your valve bag packer |

Maintenance | Regular checks and care |

Troubleshooting | Fast help in person or online |

Training | Lessons for using valve bag fillers |

Spare Parts Supply | Quick delivery of needed parts |

Pick the right valve bagging equipment and you get speed, safety, and peace of mind. Your valve bag packer becomes a trusted part of your work.

Picking the right bag on valve supplier is a big deal. It can change how your product does in the future. You should care about quality, following rules, and getting good help. Here is a simple checklist to help your business:

Look at the supplier's certificates and make sure they are real.

Ask for papers that show how they check quality.

Set up checks by other companies or ask for video proof.

Find out what help you get after buying and how to get new parts.

Make sure the safety parts are right for what you need.

Check if there are training guides you can use.

Go over these steps many times. Work with your supplier so you can grow and stay ahead of others.

FAQ

What is the main benefit of bag-on-valve technology?

Bag-on-valve technology keeps your product clean and safe. The product does not mix with the propellant. You can spray it from any direction you want. This system helps you waste less product. It is also better for the environment.

How do I know if a supplier meets quality standards?

You should ask for certificates like ISO 9001 or FDA. You can also ask for test results or outside checks. Good suppliers will give you these papers fast.

Can I customize bag-on-valve systems for my brand?

Yes, you can make changes for your brand. Suppliers let you pick bag sizes, valve types, and actuator styles. You can add your logo, pick colors, and choose special features.

What support should I expect after buying equipment?

You should get help with setting up and training. Good suppliers give you spare parts and fix problems fast. They help you keep your machines working well.

Are bag-on-valve systems safe for food and medicine?

Yes, they are safe for food and medicine. Many suppliers make these systems for food and medical use. They use safe materials and follow strict rules. Always look for FDA or CE certificates.